Preparation and application of fluorescent probe for phiophenol

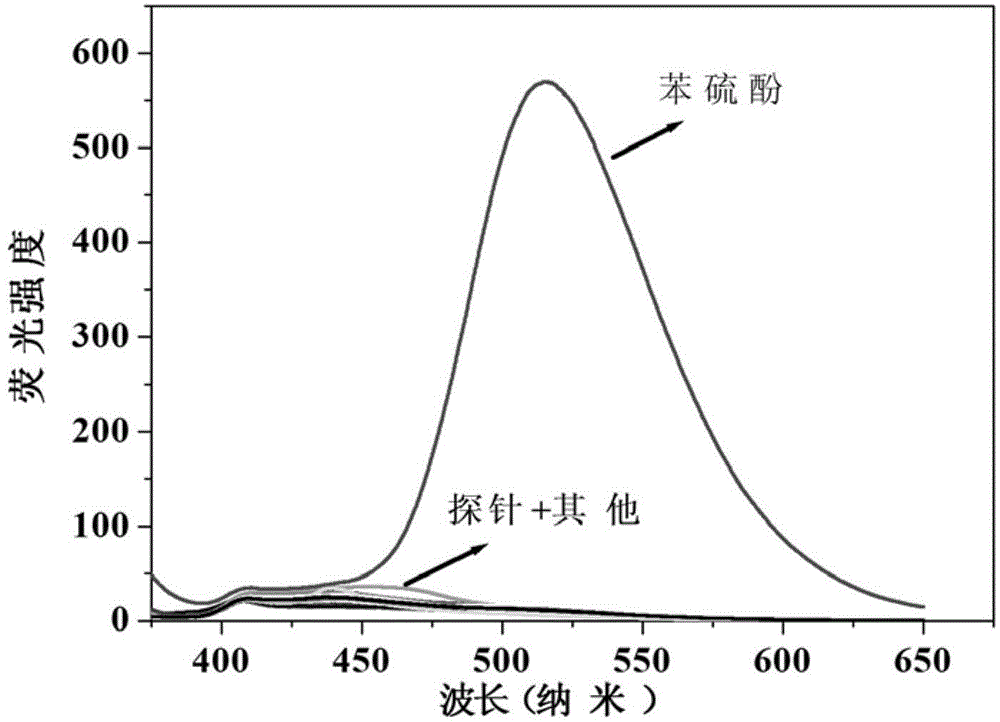

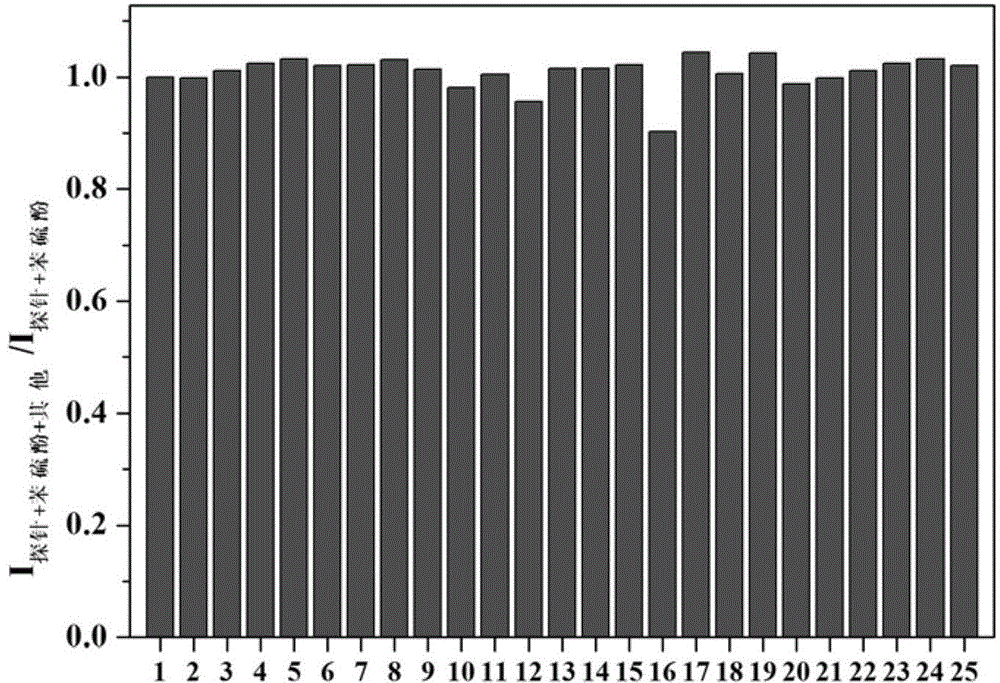

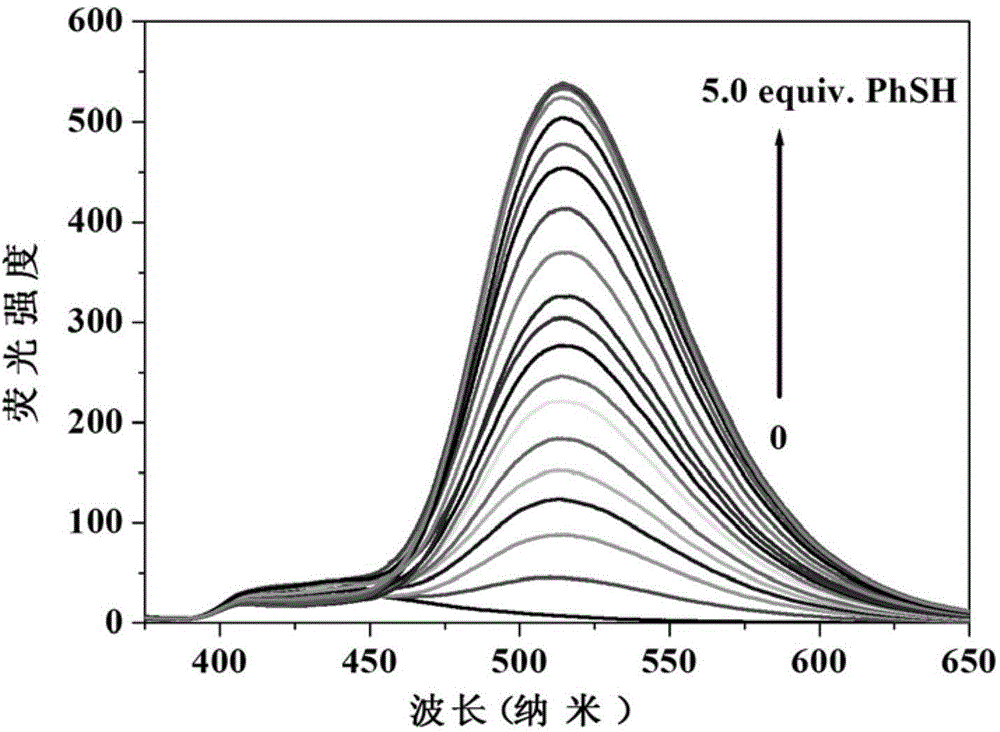

A fluorescent probe, thiophenol technology, applied in the field of chemical analysis and detection, to achieve the effects of fast response, good selectivity and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the synthesis of compound 1

[0023] 3-Nitrophthalic anhydride (1.9361g, 10mmol) was dissolved in 20ml of acetic acid, n-butylamine (1.0951g, 15mmol) was slowly added, stirred at room temperature for 10min, heated up, and refluxed at 120°C for 2.5h. After the reaction, cool to room temperature, pour the reaction solution into 50ml of cold water, and after the solid is completely precipitated, filter under reduced pressure, and wash the filter cake with cold water three times (9ml×3) to obtain compound 1 as a white solid. Yield: 2.1252 g. Yield: 85.7%. Compound 1 is characterized as follows: 1 H NMR(500MHz,DMSO):δ H 8.27(d, J=8.1Hz, 1H), 8.16(d, J=7.5Hz, 1H), 8.05(t, J=7.8Hz, 1H), 3.57(t, J=7.1Hz, 2H), 1.55– 1.61(m,2H),1.39–1.20(m,2H),0.90(t,J=7.4Hz,3H). 13 C NMR (126MHz, DMSO)δ C :166.51,163.86,144.63,136.54,134.05,128.62,127.17,123.50,38.13,30.24,19.94,13.94.

Embodiment 2

[0024] Embodiment 2: the synthesis of compound 2

[0025] Compound 1 (0.4964g, 2mmol) obtained in the previous step was dissolved in 15ml of methanol, 10%w / w Pd / C (0.0496g, 5mol%) was added, the system was vacuumed, hydrogen gas was introduced and stirred, and refluxed at 65°C for 12h. After the reaction was terminated, the solid catalyst was removed by suction filtration under reduced pressure, the obtained filtrate was rotary evaporated under reduced pressure to remove the solvent, and compound 2 was obtained by separation by chromatography column. Yield: 0.6240 g. Yield: 71.5%. Compound 2 is characterized as follows: 1H NMR (500MHz, CDCl3) δ7.42(dd, J=8.3,7.1Hz,1H),7.16(d,J=7.6Hz,1H),6.86(d,J=8.8Hz,1H),5.13(s ,1H),3.65(t,J=7.3Hz,2H),1.63–1.70(m,2H),1.35–1.42(m,2H).0.95(t,J=7.4Hz,3H). 13 C NMR (126MHz, DMSO)δ C :170.38,168.77,145.15,135.02,132.86,120.96,112.58,111.38,37.37,30.76,20.09,13.69.

Embodiment 3

[0026] Embodiment 3: the synthesis of compound 3

[0027] Compound 2 obtained in the previous step was dissolved in 10ml of 50% sulfuric acid, stirred under ice-water bath at 0°C, and aqueous sodium nitrite solution (0.0692mg, 1mmol, 2mL of water) was slowly added dropwise. After continuing to stir at 0°C for 30min, the mixture was heated to 90°C and the reaction was continued for 1h. After the reaction, pour the reaction solution into 50ml of water, extract 3 times with ethyl acetate (20mL×3), wash with saturated brine, dry over anhydrous sodium sulfate, remove the solvent by rotary evaporation, and separate by column chromatography after vacuum drying Compound 3. Yield: 0.1862 g. Yield: 85.4%. Compound 3 is characterized as follows: 1 H NMR (500MHz, CDCl3) δ7.70(s, 1H), 7.56(t, J=7.6Hz, 1H), 7.36(d, J=7.2Hz, 1H), 7.15(d, J=8.4Hz, 1H ),3.65(t,J=7.3Hz,2H),1.68–1.62(m,2H),1.40–1.32(m,2H),0.95(t,J=7.4Hz,3H). 13 C NMR (126MHz, DMSO)δ C :170.51,167.91,154.60,136.14,132.11,1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com