Tebipenem pivoxil preparation and preparation method thereof

A technology of tipipenem ester and preparation, which is applied in the field of tipipenem ester preparation and its preparation, can solve the problems of not being listed in the domestic market, and achieve the effects of high mechanical strength, less water absorption, and reduced pharmaceutical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

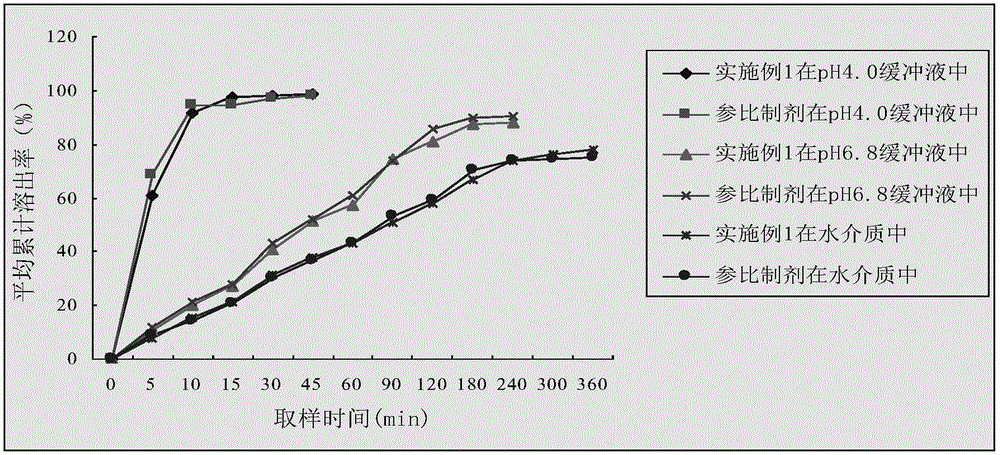

Embodiment 1

[0036] Tipipenem ester preparation of the present invention, described tipipenem ester preparation is made of granule, first coating layer and second coating layer, and described first coating layer and second coating layer increase weight average 4% by weight of pellets;

[0037] Expressed in g by weight, the granules are composed of raw materials tipipenem ester 131g (13.94%), D-mannitol 400g (42.55%) microcrystalline cellulose 300g (31.91%), sucrose 100g (10.64%) and hydroxypropyl Cellulose 9g (0.96%) composition;

[0038] Expressed in weight g, the first coating layer consists of raw material ethyl cellulose suspension 115g (55.29%), talcum powder 8g (3.85%), hydroxypropyl cellulose 5g (2.40%) and purified water 80g ( 38.46%) composition;

[0039] Expressed in weight g, the second coating layer is composed of raw material ethyl acrylate-methyl methacrylate copolymer aqueous dispersion 132g (49.77%), talcum powder 8g (3.02%), hydroxypropyl methylcellulose 4g (1.51%), asp...

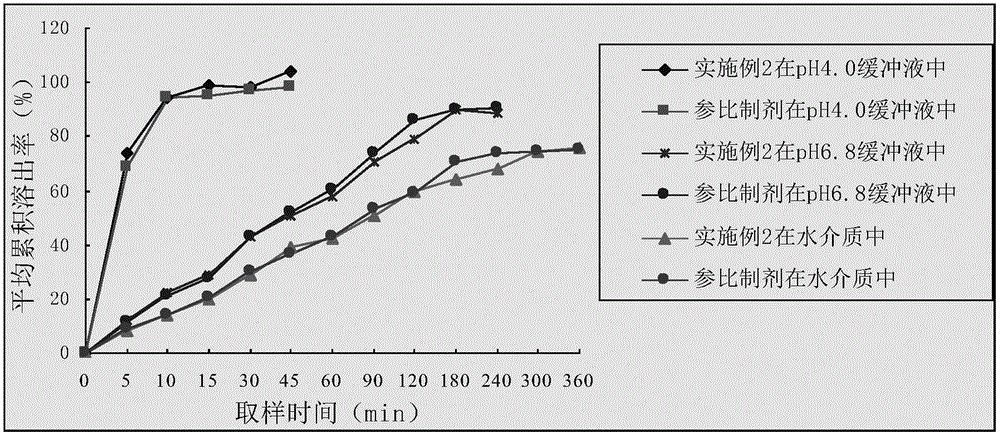

Embodiment 2

[0041] Tipipenem ester preparation of the present invention, described tipipenem ester preparation is made of granule, first coating layer and second coating layer, and described first coating layer and second coating layer increase weight average 3.5% by weight of the pellets;

[0042] Expressed in g by weight, the granules are composed of raw materials tipipenem ester 131g (13.94%), D-mannitol 380g (40.43%) microcrystalline cellulose 320g (34.03%), sucrose 100g (10.64%) and hydroxypropyl Cellulose 9g (0.96%) composition;

[0043] Expressed in weight g, the first coating layer consists of raw material ethyl cellulose suspension 115g (55.29%), talcum powder 8g (3.85%), hydroxypropyl cellulose 5g (2.40%) and purified water 80g ( 38.46%) composition;

[0044] Expressed in weight g, the second coating layer is composed of raw material ethyl acrylate-methyl methacrylate copolymer aqueous dispersion 132g (49.77%), talcum powder 8g (3.02%), hydroxypropyl methylcellulose 4g (1.51%...

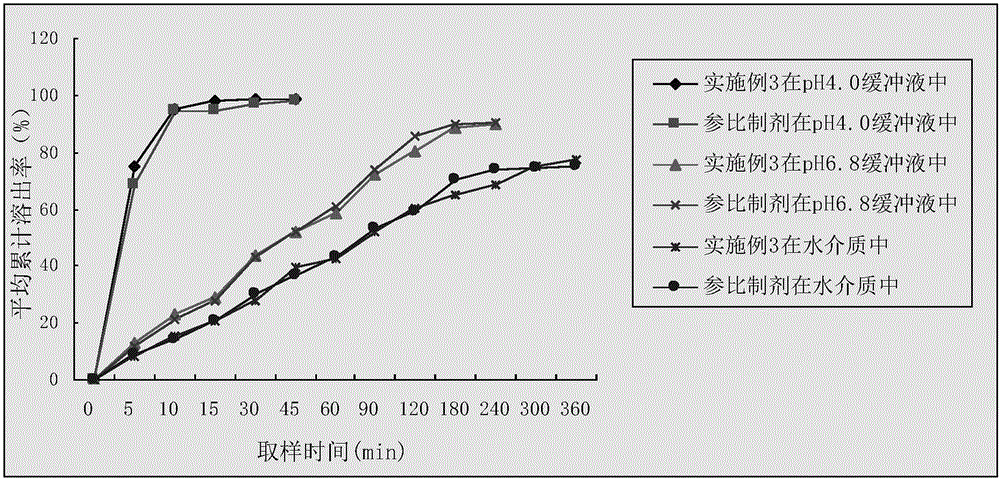

Embodiment 3

[0046] Tipipenem ester preparation of the present invention, described tipipenem ester preparation is made of granule, first coating layer and second coating layer, and described first coating layer and second coating layer increase weight average 3% by weight of pellets;

[0047] Expressed in g by weight, the granules are composed of raw materials tipipenem ester 131g (13.94%), D-mannitol 420g (44.68%) microcrystalline cellulose 280g (29.78%), sucrose 100g (10.64%) and hydroxypropyl Cellulose 9g (0.96%) composition;

[0048] Expressed in weight g, the first coating layer consists of raw material ethyl cellulose suspension 115g (55.29%), talcum powder 8g (3.85%), hydroxypropyl cellulose 5g (2.40%) and purified water 80g ( 38.46%) composition;

[0049] Expressed in weight g, the second coating layer is composed of raw material ethyl acrylate-methyl methacrylate copolymer aqueous dispersion 132g (49.77%), talcum powder 8g (3.02%), hydroxypropyl methylcellulose 4g (1.51%), asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com