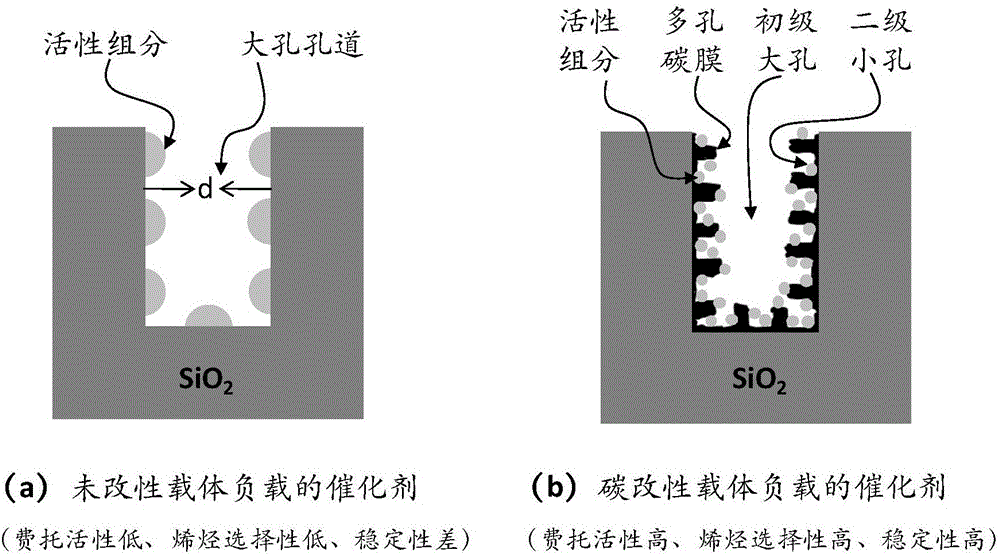

Preparation and application of carbon modified silicon dioxide carrier loaded iron-based catalyst for Fischer-Tropsch synthesis

An iron-based catalyst, silica technology, applied in the direction of catalyst activation/preparation, hydrocarbon production from carbon oxides, carbon compound catalysts, etc., can solve the problems of low Fischer-Tropsch activity, difficulty in improving activity and olefin selectivity, and achieve The effect of low cost, low requirements for raw material composition, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

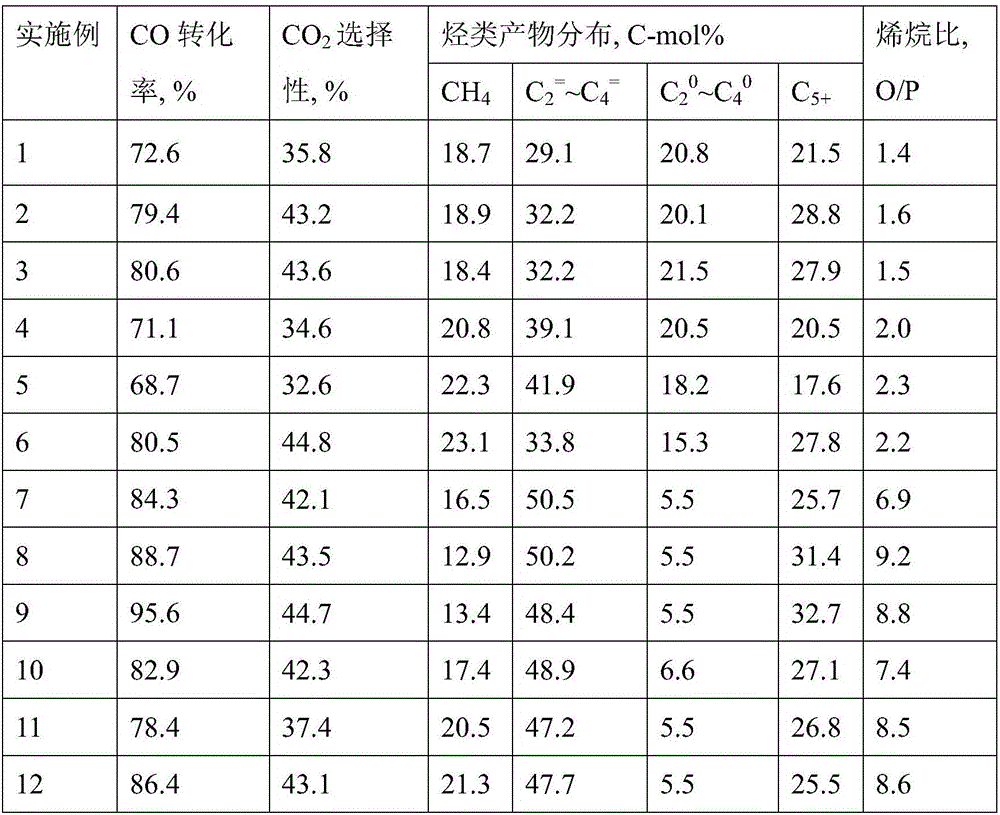

Embodiment 1

[0027] 1) Preparation of carbon-modified silica support 5C-S10. Make 1.189g sucrose into an aqueous solution, impregnate an equal volume in 10g SiO 2(S-10) on the carrier, impregnated at room temperature for 10h, then dried by rotary evaporation, and finally in a nitrogen atmosphere at 450°C for 4000h -1 Calcined at the bottom for 4 hours to obtain carbon-modified silica carrier 5C-S10.

[0028] 2) Preparation of 15Fe / 5C-S10 catalyst. 10.821g Fe(NO 3 ) 3 9H 2 O was made into an aqueous solution, and an equal volume was impregnated on 8.5 g of the carrier obtained in step 1). After impregnated at room temperature for 2 hours, it was rotated to dryness at 80°C under negative pressure and dried at 120°C for 12 hours. Finally, in nitrogen atmosphere, 300°C, 5000h -1 Calcined for 5 hours, the catalyst 15Fe / 5C-S10 was prepared.

[0029] 3) Activity test. The activity of the prepared catalysts was evaluated in a fixed bed reactor. The catalyst is first reduced in situ, and ...

Embodiment 2

[0031] 1) Preparation of carbon-modified silica support 10C-S10. Make 2.378g sucrose into an aqueous solution, impregnate an equal volume in 10g SiO 2 (S-10) on the carrier, impregnated at room temperature for 10h, then dried by rotary evaporation, and finally in a nitrogen atmosphere at 450°C for 4000h -1 Calcined at the bottom for 4 hours to obtain carbon-modified silica carrier 10C-S10.

[0032] 2) Preparation of 15Fe / 10C-S10 catalyst. 10.821g Fe(NO 3 ) 3 9H 2 O was made into an aqueous solution, and an equal volume was impregnated on 8.5 g of the carrier obtained in step 1). After impregnated at room temperature for 2 hours, it was rotated to dryness at 80°C under negative pressure and dried at 120°C for 12 hours. Finally, in nitrogen atmosphere, 300°C, 5000h -1 Under roasting for 5h, the catalyst 15Fe / 10C-S10 was prepared.

[0033] 3) The activity test is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0035] 1) Preparation of carbon-modified silica support 15C-S10. Make 3.567g sucrose into an aqueous solution, impregnate equal volume in 10g SiO 2 (S-10) on the carrier, impregnated at room temperature for 10h, then dried by rotary evaporation, and finally in a nitrogen atmosphere at 450°C for 4000h -1 Calcined at the bottom for 4h to obtain carbon-modified silica carrier 15C-S10.

[0036] 2) Preparation of 15Fe / 15C-S10 catalyst. 10.821g Fe(NO 3 ) 3 9H 2 O was made into an aqueous solution, and an equal volume was impregnated on 8.5 g of the carrier obtained in step 1). After impregnated at room temperature for 2 hours, it was rotated to dryness at 80°C under negative pressure and dried at 120°C for 12 hours. Finally, in nitrogen atmosphere, 300°C, 5000h -1 Calcined for 5 hours, the catalyst 15Fe / 15C-S10 was prepared.

[0037] 3) The activity test is the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com