Preparation method of titanium dioxide according to chlorination method

A technology of titanium dioxide and chlorination method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of excessive cooling time, uneven particle size distribution, and affecting the quality of pigments, so as to prevent high-temperature shutdown accidents, particle Good dispersion and uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

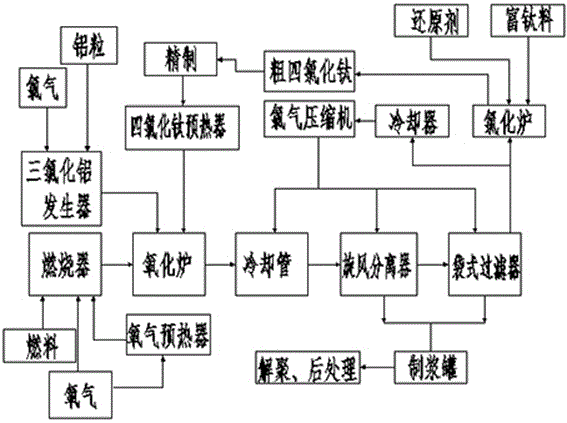

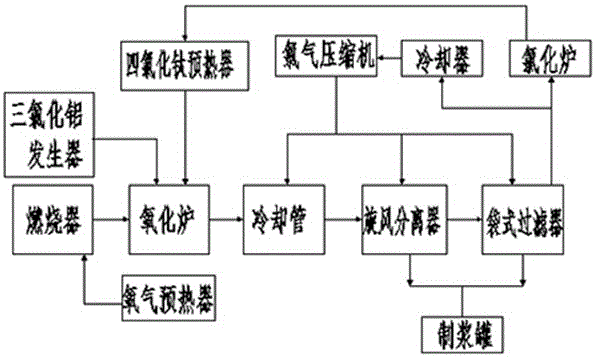

[0030] Such as figure 1 The preparation method of the chlorination method titanium dioxide of the present invention comprises the following steps:

[0031] 1. Mix high-titanium slag and petroleum coke evenly, put it into a chlorination furnace, and inject chlorine gas to carry out boiling chlorination at a temperature of 900°C.

[0032] 2. Separating and purifying the crude titanium tetrachloride obtained after chlorination to remove impurities such as magnesium, iron, silicon and vanadium to obtain refined titanium tetrachloride.

[0033]3. The obtained refined titanium tetrachloride liquid is preheated in a preheater and converted into a gas phase.

[0034] 4. Indirect heating, vaporization and preheating of titanium tetrachloride passing through the preheater to 400°C by combustion of natural gas, etc.; gaseous titanium tetrachloride continues to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com