Method for efficiently treating plant protein wastewater

A plant protein and treatment method technology, which is applied in the field of protein wastewater treatment, can solve problems such as high SS content, unstable water pH, and difficult microbial degradation of suspended matter, so as to promote dissolution and destruction, improve SS removal rate, and solve the problem of SS removal. Incomplete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

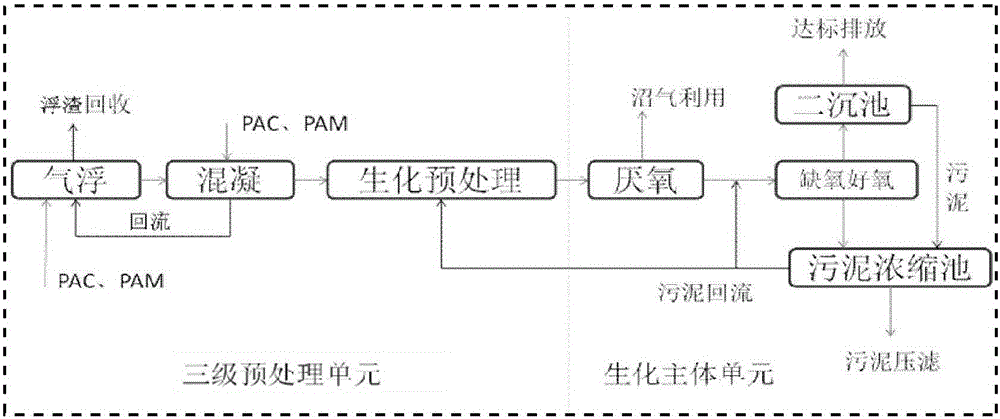

[0035] combined with figure 1 , a process technology method for efficient treatment of vegetable protein wastewater of the present embodiment, the steps are:

[0036] (A) The production wastewater of a vegetable protein company in Shandong first enters the air flotation unit. The air flotation tank adopts the conventional dissolved air flotation process, the reflux ratio is 80%, and 600mg / L polyaluminum chloride (PAC for short) is added to the air flotation tank. , and then add 10mg / L of polyacrylamide (referred to as PAM), the scraped scum in the air flotation tank is recovered through the filter press device, and the filtrate is returned to the air flotation tank;

[0037] (B) The effluent of the air flotation tank enters the coagulation reaction tank of the coagulation unit. The coagulation unit adopts a conventional coagulation sedimentation process, including a coagulation reaction tank and a coagulation sedimentation tank. The coagulation reaction tank adopts mechanical...

Embodiment 2

[0043] A kind of technological method of the high-efficiency treatment of vegetable protein waste water of the present embodiment, its steps are:

[0044] (A) The production wastewater of a vegetable protein company in Shandong first enters the air flotation unit. The air flotation tank adopts the conventional dissolved air flotation process, and the reflux ratio is 80%. 1000mg / L of PAC is added to the air flotation tank, and then 20mg / L is added. PAM, the scraped scum is recovered through the filter press device, and the filtrate is returned to the air flotation unit;

[0045] (B) The effluent of the air flotation tank enters the coagulation reaction tank of the coagulation unit. The coagulation unit adopts a conventional coagulation sedimentation process, including a coagulation reaction tank and a coagulation sedimentation tank. The coagulation reaction tank adopts mechanical stirring with a stirring rate of 400 Turn per minute, maintain the pH condition of the raw water, a...

Embodiment 3

[0051] A kind of technological method of the high-efficiency treatment of vegetable protein waste water of the present embodiment, its steps are:

[0052] (A) The production wastewater of a vegetable protein company in Shandong first enters the air flotation unit. The air flotation tank adopts the conventional dissolved air flotation process, and the reflux ratio is 80%. 50mg / L of PAC is added to the air flotation tank, and then 2mg / L is added. PAM, the scraped scum is recovered through the filter press device, and the filtrate is returned to the air flotation unit;

[0053] (B) The effluent of the air flotation tank enters the coagulation reaction tank of the coagulation unit. The coagulation unit adopts a conventional coagulation sedimentation process, including a coagulation reaction tank and a coagulation sedimentation tank. The coagulation reaction tank adopts mechanical stirring with a stirring rate of 400 Turn per minute, maintain the pH condition of the raw water, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com