Non-asphalt-based high polymer self-adhered waterproof membrane with high peel strength and preparation method of non-asphalt-based high polymer self-adhered waterproof membrane

A self-adhesive waterproof membrane and polymer-based technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of not being able to obtain self-adhesive waterproof membranes, low peel strength, and poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

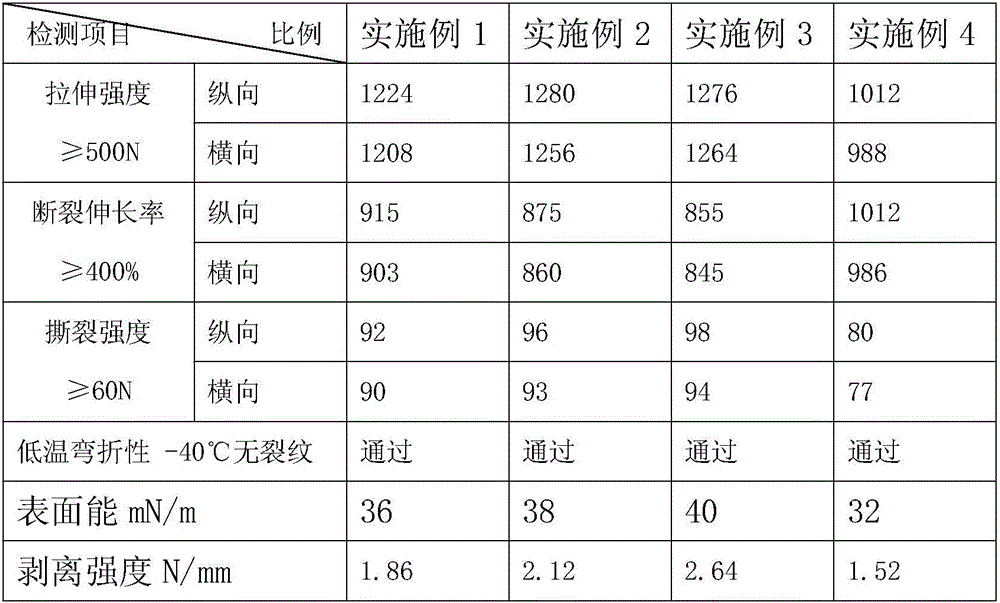

Examples

Embodiment 1

[0021] A preparation of high peel strength non-bitumen-based self-adhesive membrane polymer sheet: calculated in parts by weight, including: 70 parts of low-density polyethylene (LDPE), 5 parts of maleic anhydride graft modified polyethylene (MAH -g-PE), 25 parts of light calcium carbonate, 0.2 part of UV-9 ultraviolet absorber, 0.1 part of 1010 primary antioxidant, 0.2 part of 168 auxiliary antioxidant, 0.3 parts of stearic acid and 3 parts of iron dioxide.

[0022] The steps of a production process of a TPO waterproof coiled material are as follows:

[0023] a. Mixing: Mix the measured raw materials (mixing conditions) evenly:

[0024] b. Extrusion and calendering: the mixed raw materials are plasticized and extruded through a twin-screw extruder. At 220±10°C, the extruded sheet is calendered by a three-roller calender;

[0025] c. Glue coating: The calendered polymer sheet is glued on the glue coating machine, using SIS pressure-sensitive hot melt adhesive, the melting t...

Embodiment 2

[0028] A non-bitumen-based polymer self-adhesive waterproofing membrane with high peel strength. Under other conditions that are completely the same as in Example 1, and the total amount of resin remains unchanged, only the low-polarity resin and the modified resin are changed. The proportioning, the weight parts of other components do not change, take LDPE:MAH-g-PE=65:10 in embodiment 2, and produce according to the production process of waterproof roll material described in embodiment 1, prepare non- Bitumen-based polymer self-adhesive waterproofing membrane.

Embodiment 3

[0030] A non-bitumen-based polymer self-adhesive waterproofing membrane with high peel strength. Under other conditions that are completely the same as in Example 1, and the total amount of resin remains unchanged, only the low-polarity resin and the modified resin are changed. The proportioning, the parts by weight of other components do not change, take LDPE:MAH-g-PE=60:15 in embodiment 3, and produce according to the production process of waterproof roll material described in embodiment 1, prepare non- Bitumen-based polymer self-adhesive waterproofing membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com