Modified nano carbon material, carbon material/polymer composite material and preparation method thereof

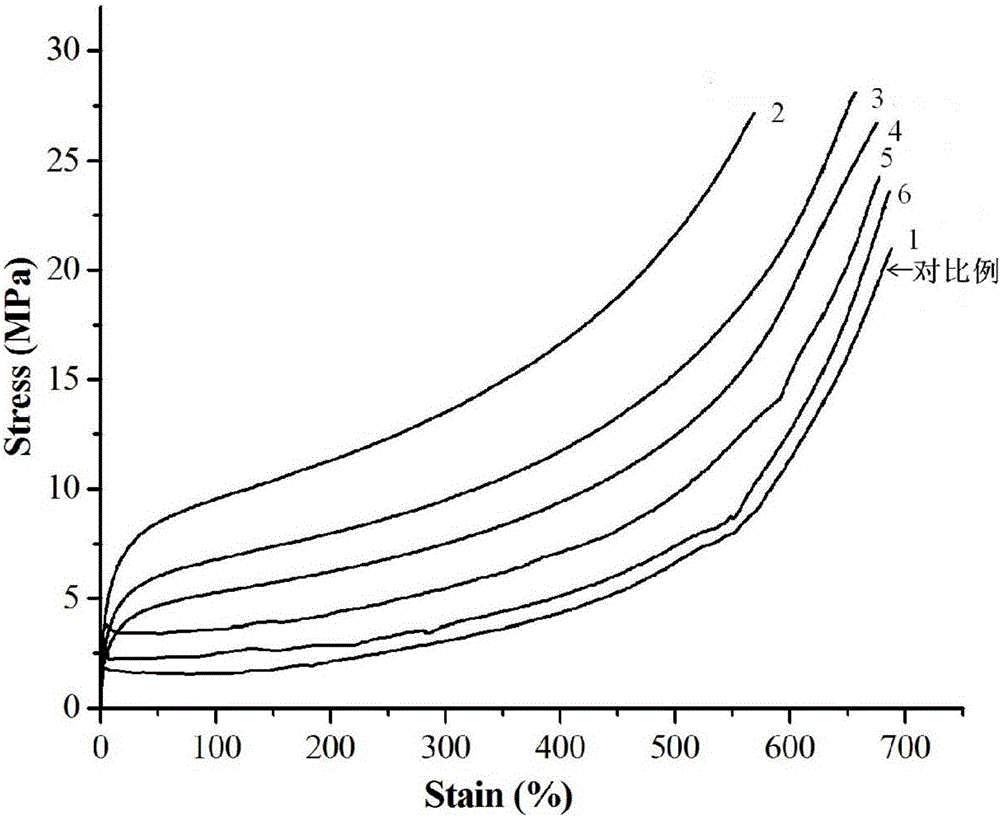

A technology of nano-carbon materials and composite materials, which is applied in the field of modified carbon materials, carbon materials/polymer composite materials and their preparation, can solve the problems of poor dispersion and compatibility of nano-carbon materials, and achieve improved mechanical properties and thermal properties. Effects of stability, method simplicity, and low permeation threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The modified carbon material provided in this example includes a polycyclic aromatic hydrocarbon-terminated polymer containing a functional group and a carbon nanomaterial, and the polycyclic aromatic hydrocarbon-terminated polymer containing a functional group and the carbon nanomaterial are dispersed in an organic solvent .

[0052] The preparation method of the modified carbon material provided by this embodiment comprises the following steps:

[0053] Add functional group-containing polycyclic aromatic hydrocarbons into the polymer, and react to obtain functional group-containing polycyclic aromatic hydrocarbon-terminated polymers; then disperse the functional group-containing polycyclic aromatic hydrocarbon-terminated polymers and carbon materials in organic solvents to obtain modified carbon materials.

[0054] The carbon material / polymer composite material provided in this embodiment includes the above-mentioned modified carbon material and polymer.

[0055] Th...

Embodiment 2

[0058] The modified carbon material provided in this embodiment includes perylene anhydride-capped polyisoprene (PBIPI) and nano-graphite material, and the PBIPI and nano-graphite material are dispersed in tetrahydrofuran.

[0059] Specifically, the preparation method of the modified carbon material provided in this embodiment includes the following steps:

[0060] S21. Using butyl lithium to initiate the polymerization of isoprene monomer to obtain a polymer, and then adding perylene anhydride to the polymer, and reacting at 60° C. for 5 hours to obtain perylene anhydride-capped polyisoprene ( PBIPI);

[0061] S22. Add PBIPI and nano-carbon material into tetrahydrofuran, stir at room temperature for 3 hours, centrifuge, remove the lower precipitate and re-add it into tetrahydrofuran for dispersion, repeat 3 times, and obtain the modified carbon material.

[0062] The carbon material / polymer composite material provided in this embodiment includes the above-mentioned modified ...

Embodiment 3

[0066] The modified carbon material provided in this embodiment includes perylene anhydride-capped polypiperylene (PBIPPD) and nano-graphite material, and the PBIPPD and nano-graphite material are dispersed in tetrahydrofuran.

[0067] Specifically, the preparation method of the modified carbon material provided in this embodiment includes the following steps:

[0068] S31. Using butyl lithium to initiate the polymerization of piperylene monomer to obtain a polymer, and then adding perylene anhydride to the polymer, and reacting at 60° C. for 5 hours to obtain perylene anhydride-terminated polypiperylene ( PBIPPD);

[0069] S32. Add PBIPPD and nano-carbon material into tetrahydrofuran, stir at room temperature for 7 hours, centrifuge, remove the lower precipitate and re-add it into tetrahydrofuran for dispersion, repeat 5 times, and obtain the modified carbon material.

[0070] The carbon material / polymer composite material provided in this embodiment includes the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com