Novel ink melanin extraction method

A technology of ink melanin and a new method, which is applied in the field of ink melanin extraction, can solve the problems of difficult separation and purification, environmental pollution, waste of resources, etc., and achieve the effects of reducing environmental pollution, high purity, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

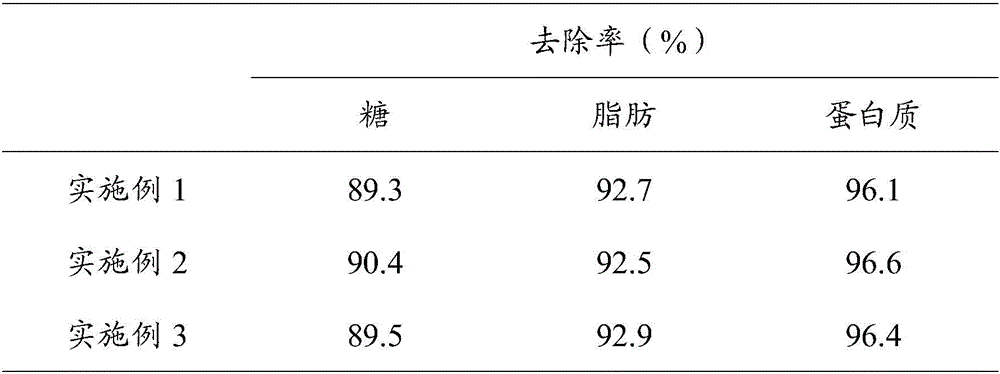

Examples

Embodiment 1

[0022] A new method for extracting melanin, the new method for extracting melanin comprises the following steps:

[0023] 1) Microwave removal of polysaccharides: Wash and mash squid ink sacs, rotate at a speed of 30r / min and apply 120uW / cm2 ultraviolet radiation for 5min, add sterile water at a material-liquid ratio of 1:12, and microwave for 15min at a power of 300W , centrifuge to remove the supernatant, and take the precipitate; during this period, the sugar content before and after the treatment of the squid ink sac is detected;

[0024] 2) Ultrasonic fat removal: add sodium lauryl polyoxyethylene ether carboxylate with a concentration of 1.8% to the precipitate obtained in step 1), the ratio of solid to liquid is 1:4, and ultrasonically treat for 40 minutes, wherein the ultrasonic power is 180W, and the supernatant is removed , the precipitate was rinsed with sterile water; during this period, the fat content of the squid ink sac before and after treatment was detected; ...

Embodiment 2

[0027] A new method for extracting melanin, the new method for extracting melanin comprises the following steps:

[0028] 1) Microwave removal of polysaccharides: wash and mash the octopus ink sacs, rotate at a speed of 40r / min and apply 135uW / cm2 ultraviolet radiation for 6.5min, add sterile water at a solid-liquid ratio of 1:14, microwave radiation at a power of 375W 12.5min, centrifuge to remove the supernatant, and take the precipitate; during this period, detect the sugar content of the squid ink sac before and after treatment;

[0029] 2) Ultrasonic fat removal: Add sodium lauryl polyoxyethylene ether carboxylate with a concentration of 1.65% to the precipitate obtained in step 1), the ratio of solid to liquid is 1:6, and ultrasonically treat for 60 minutes, wherein the ultrasonic power is 220W, and the supernatant is removed , the precipitate was rinsed with sterile water; during this period, the fat content of the squid ink sac before and after treatment was detected; ...

Embodiment 3

[0032] A new method for extracting melanin, the new method for extracting melanin comprises the following steps:

[0033] 1) Microwave removal of polysaccharides: wash and mash the squid ink sac, rotate at a speed of 50r / min and apply 150uW / cm2 ultraviolet radiation for 8min, add sterile water at a material-liquid ratio of 1:16, microwave radiation at 450W power 12.5 min, centrifuge to remove the supernatant, and take the precipitate; during this period, the sugar content before and after the treatment of the squid ink sac is detected;

[0034] 2) Ultrasonic fat removal: add sodium lauryl polyoxyethylene ether carboxylate with a concentration of 1.65% to the precipitate obtained in step 1), the ratio of solid to liquid is 1:5, and ultrasonically treat for 50 minutes, wherein the ultrasonic power is 200W, and the supernatant is removed , the precipitate was rinsed with sterile water; during this period, the fat content of the squid ink sac before and after treatment was detecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com