Method for preparing nickel-boron alloy coating on continuous casting crystallizer copper plate surface

A technology for continuous casting mold and nickel-boron alloy, which is applied in the field of preparing nickel-boron alloy coating on the surface of continuous casting mold copper plate, can solve the problem that nickel-boron alloy is not fully suitable for mold copper plate coating, etc., so as to improve the surface quality of the coating and ensure The effect of normal operation and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

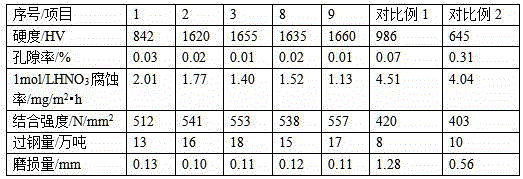

Examples

Embodiment 1

[0036] The method for preparing the nickel-boron alloy coating on the surface of the copper plate of the continuous casting crystallizer in this embodiment, the specific steps are as follows:

[0037] Step S1, pretreatment: cleaning the machined copper plate with an organic solvent, sandblasting, electrolytic degreasing, ultrasonic cleaning and acid activation treatment to obtain the base material of the copper plated plate;

[0038] Step S2, electroplating: inject the electroplating solution into the electroplating tank, adjust the pH of the electroplating solution to 4.0, heat the electroplating solution, and raise the temperature to 55° C., then put the base material of the plate to be copper-plated as the cathode into the electroplating tank, and put Put the anode into the electroplating tank, turn on the power and start electroplating, until the thickness of the nickel-boron alloy coating reaches the set value, the electroplating ends;

[0039] Step S3, post-processing: t...

Embodiment 2

[0045] In the method for preparing a nickel-boron alloy coating on the surface of a continuous casting crystallizer copper plate in this embodiment, the composition of the electroplating solution and the electroplating conditions are the same as in Example 1, steps S1 to S2 are the same as in Example 1, and step S3 also includes:

[0046] Place the electroplated copper plate in a vacuum furnace with a vacuum degree of 6.67×10 -3 Pa, heat treatment at 400°C for 4h.

[0047] The mass fraction of boron in the nickel-boron alloy obtained by the method of this embodiment is 4.2%.

Embodiment 3

[0049] In the method for preparing the nickel-boron alloy coating on the surface of the continuous casting crystallizer copper plate of the present embodiment, the composition of the electroplating solution is:

[0050] Nickel sulfamate 60g / L, boric acid 40g / L, sodium borohydride 5g / L, ethylenediamine 42g / L, sodium dodecylsulfonate 0.06g / L, benzyl-alkenylpyridine inner salt 0.010g / L L, propynyl alcohol 0.025g / L, sodium allyl sulfonate 1.5mg / L;

[0051] The pH value of the electroplating solution is 4.0, the temperature is 55°C, the copper substrate is the cathode, the nickel beads are the anode, and the current density is controlled at 2.0A / dm 2 .

[0052] The specific preparation method is the same as in Example 2, and will not be repeated. The mass fraction of boron in the nickel-boron alloy obtained by the method of this embodiment is 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average wear | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com