Quantum dot surface purification method for improving luminous efficiency of perovskite LED

A technology of luminous efficiency and quantum dots, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of complex operation, can not improve device performance well, achieve good crystallinity, simple surface treatment method, reduce ligands effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

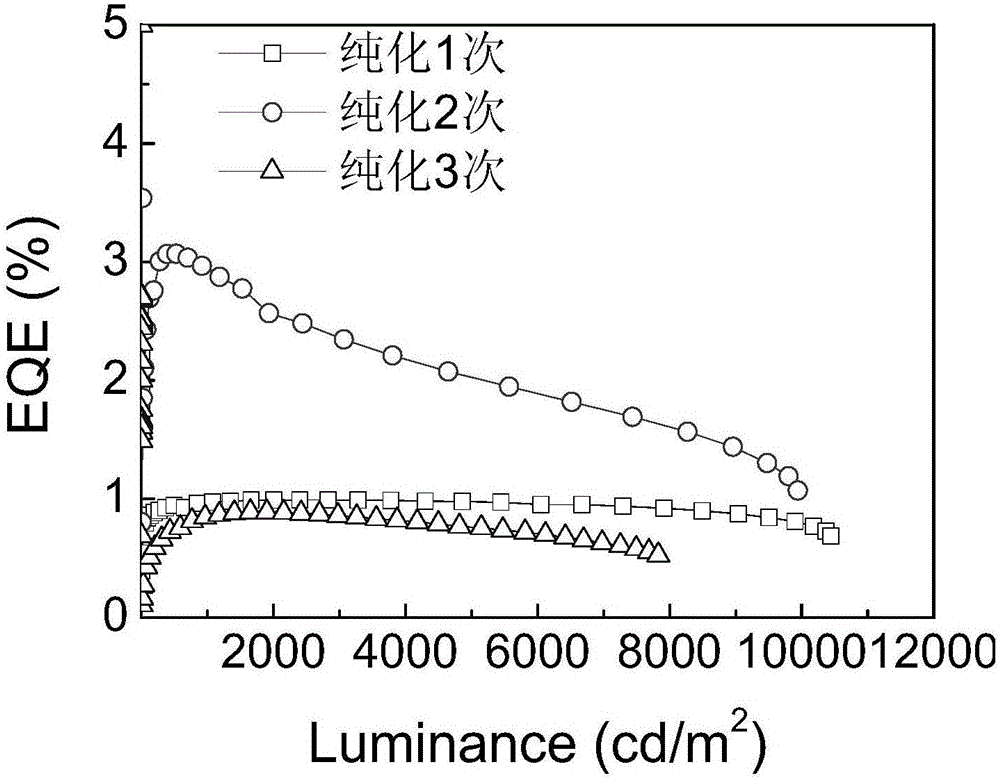

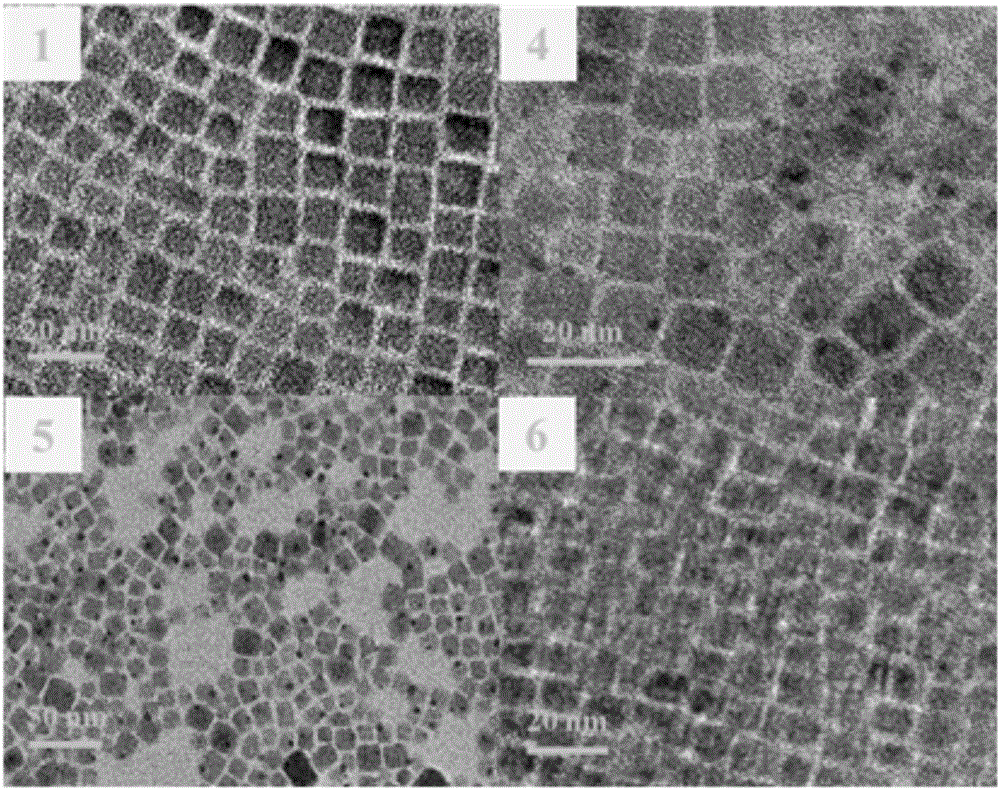

Embodiment 1

[0029] 1) Dissolve 2.5g of Cs(st) in 40mL of octadecene, heat and stir to dissolve completely, and make a cesium precursor solution;

[0030] 2) Add 0.198g of PbBr 2 Dissolve in a mixed solution of 1.5mL oleic acid, 1mL oleylamine and 15mL octadecene, repeatedly evacuate-fill with argon, cycle for 10min, exhaust oxygen and water, and ensure that the reaction system is protected by an inert atmosphere;

[0031] 3) Heat and stir at 120°C, continue heating for 10 minutes until the reactants are fully dissolved, then raise the temperature to 170°C;

[0032] 4) Take 0.55g of the cesium precursor solution in step 1), quickly inject it into the mixed solution, react for 5s, and quickly ice-bath to room temperature to obtain the CsPbBr3 quantum dot stock solution;

[0033] 5) In CsPbX 3 Add 20mL acetone and 20mL ethyl acetate to the stock solution of quantum dots, centrifuge at 10000rpm / 1min, pour off the supernatant, and take the precipitate;

[0034] 6) Dissolve the precipitate i...

Embodiment 2

[0038] Using the same process as in Example 1, the difference is that step 6) in Example 1 is not operated, and the precipitate obtained in step 5) is directly combined with step 7), and other conditions remain the same.

Embodiment 3

[0040] The same process as in Example 1 was adopted, except that step 6) was repeated before step 7) in Example 1, and other conditions remained the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com