Iron-plated graphene and preparation method

A graphene and iron plating technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve problems such as insufficient absorption strength, large thickness, and high structural requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

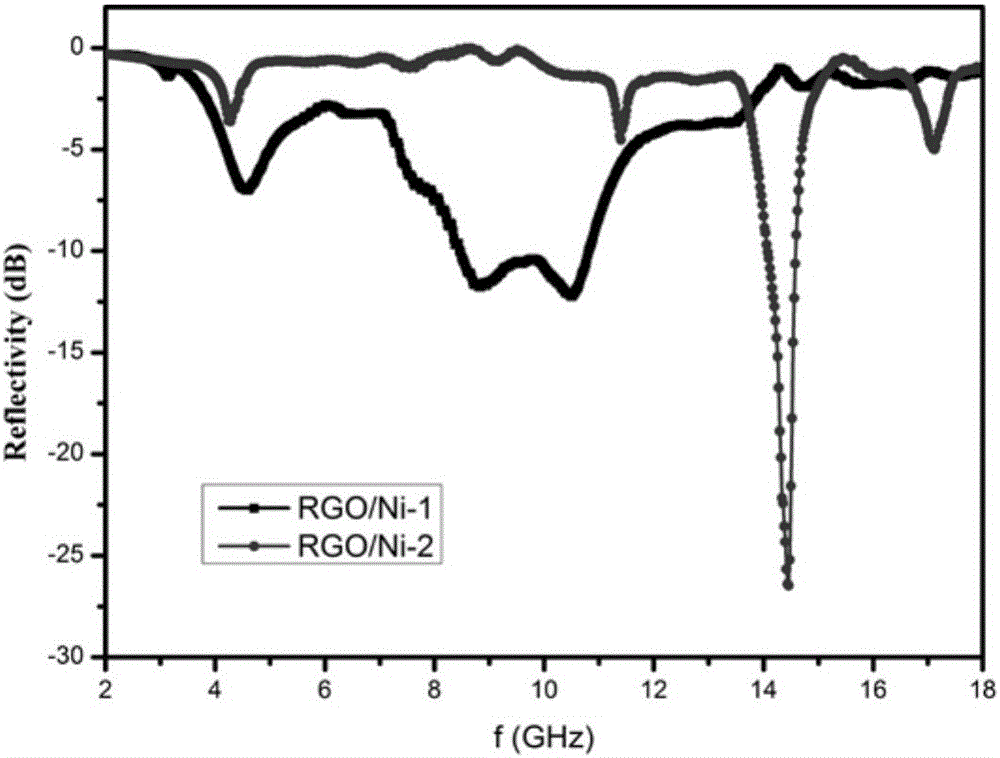

[0043] The preparation method of iron-coated graphene provided in this embodiment, the graphene used is prepared by the improved Hummer method, and the iron / graphene composite material is prepared with graphene, reducing agent, iron salt, stabilizer, complexing agent, surface treatment agent, pH The regulator is used as a raw material and prepared by an in situ reduction method. And the prepared iron / graphene composite material is prepared into a wave-absorbing layer and applied to the shielding layer of the anti-interference electric meter box. The specific preparation method is as follows:

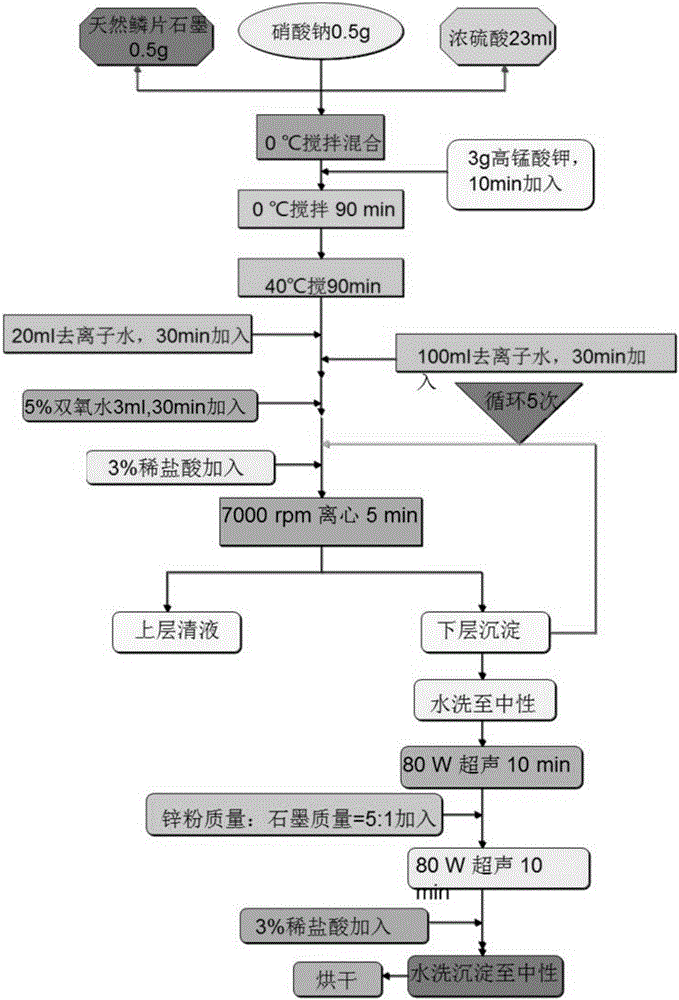

[0044] 0.5~0.8g graphite, 0.5~0.8g NaNo 3 and 23~30mL concentrated H 2 SO 4 Mix and stir under ice bath, add 3~5g KMnO 4 Graphite oxide; graphite oxide prepared by ultrasound can obtain graphene oxide; its specific flow chart is as follows:

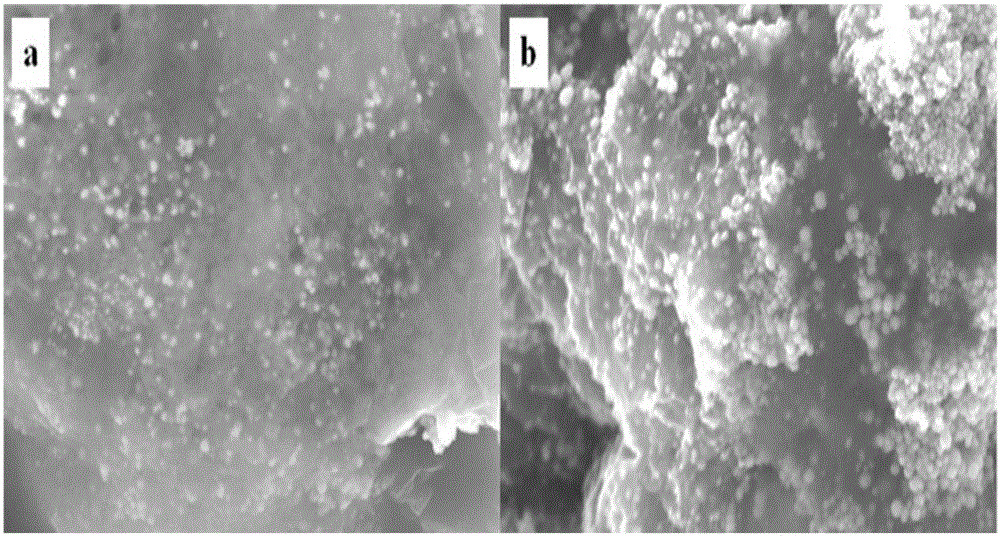

[0045] The iron-coated graphene is prepared by reacting graphene, a reducing agent, an iron salt, a stabilizer, a complexing agent, a surface ...

Embodiment 2

[0060] The preparation method of iron / graphene composite material in the present embodiment, comprises the following steps:

[0061] Prepare graphene:

[0062] Mix natural flake graphite, sodium nitrate and concentrated sulfuric acid under an ice bath and stir to form a mixed solution;

[0063] Add potassium permanganate to the mixed solution to prepare graphene oxide by ultrasonic;

[0064] Dissolve sodium borohydride, ferrous sulfate heptahydrate and sodium hydroxide in appropriate amount of deionized water respectively;

[0065] Sodium borohydride and sodium hydroxide solution are mixed to make A solution;

[0066] Graphene oxide and ferrous sulfate heptahydrate solution are mixed to make B solution;

[0067] Add solution A and solution B dropwise into the reaction tank for full reaction so that nano-iron particles grow on the surface of graphene;

[0068] The graphene coated with nano-iron particles was obtained by suction filtration, and dried in a vacuum oven to obta...

Embodiment 3

[0097] The graphene provided in this example is prepared by a redox method, and a layer of nanoparticles is coated on the surface of the obtained graphene by an in-situ reduction method; the specific preparation method is:

[0098] 0.5g graphite, 0.5g NaNo 3 and 23 mL concentrated H 2 SO 4 Mix and stir under ice bath, add 3 g KMnO 4 Graphite oxide; graphite oxide prepared by ultrasound can be used to obtain graphene oxide. The specific process is as follows:

[0099] Firstly, graphene is prepared by oxidation-reduction method, and then a layer of nanoparticles is coated on the surface of obtained graphene by in-situ reduction method; the specific preparation method includes the following steps:

[0100] Mix 0.5g of natural flake graphite, 0.5g of sodium nitrate and 423mL of concentrated sulfuric acid in an ice bath and stir for 10 minutes;

[0101] Add 3 g of potassium permanganate, mix and stir in an ice bath for 90 minutes;

[0102] Raise the temperature of the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com