Polycarbonate and optical member including same

A polycarbonate and optical component technology, applied in optical components, optical components, optics, etc., can solve the problems of low fluidity and poor formability of copolycarbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

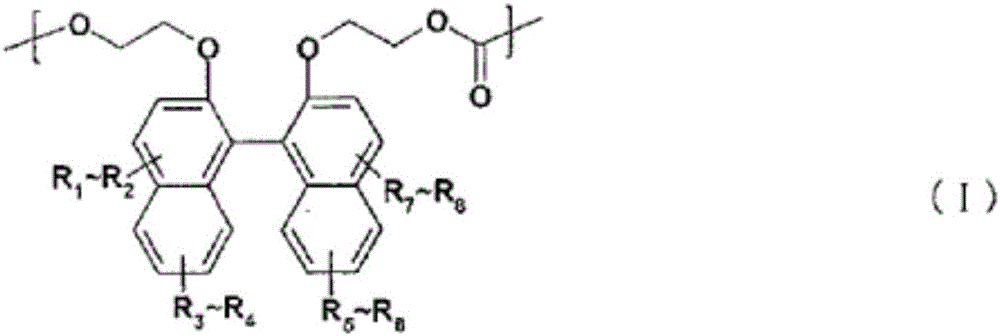

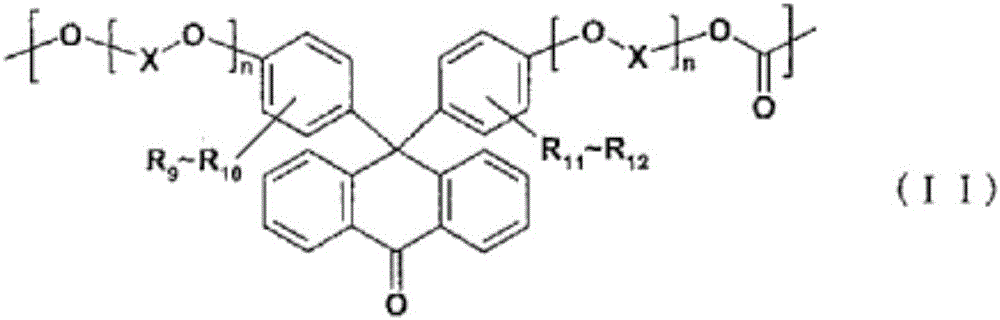

Method used

Image

Examples

Embodiment

[0109] Hereinafter, the present invention will be further described with reference to examples.

[0110] 1. A sample for evaluation was prepared by the following method.

[0111] (a) Cast film:

[0112] 5 g of the obtained polycarbonate was dissolved in 50 ml of methylene chloride, and cast on a glass dish. After sufficiently drying at room temperature, the polycarbonate was dried at a temperature of 20° C. or lower for 8 hours to produce a cast film.

[0113] (b) spherical lens:

[0114] After the obtained polycarbonate was vacuum-dried at 120°C for 8 hours, the molding temperature was set to Tg+110°C, the mold temperature was set to Tg-10°C, and the injection molding machine with a thickness of 0.2 mm, convex curvature radius 5mm, concave curvature radius 4mm, Φ5mm lens.

[0115] (c) Formed sheet

[0116] Molded sheets having a width of 2.5 cm, a length of 5 cm, and a thickness of 1, 2, and 3 mm were injection-molded in the same manner as in (b) above.

[0117] 2. Eval...

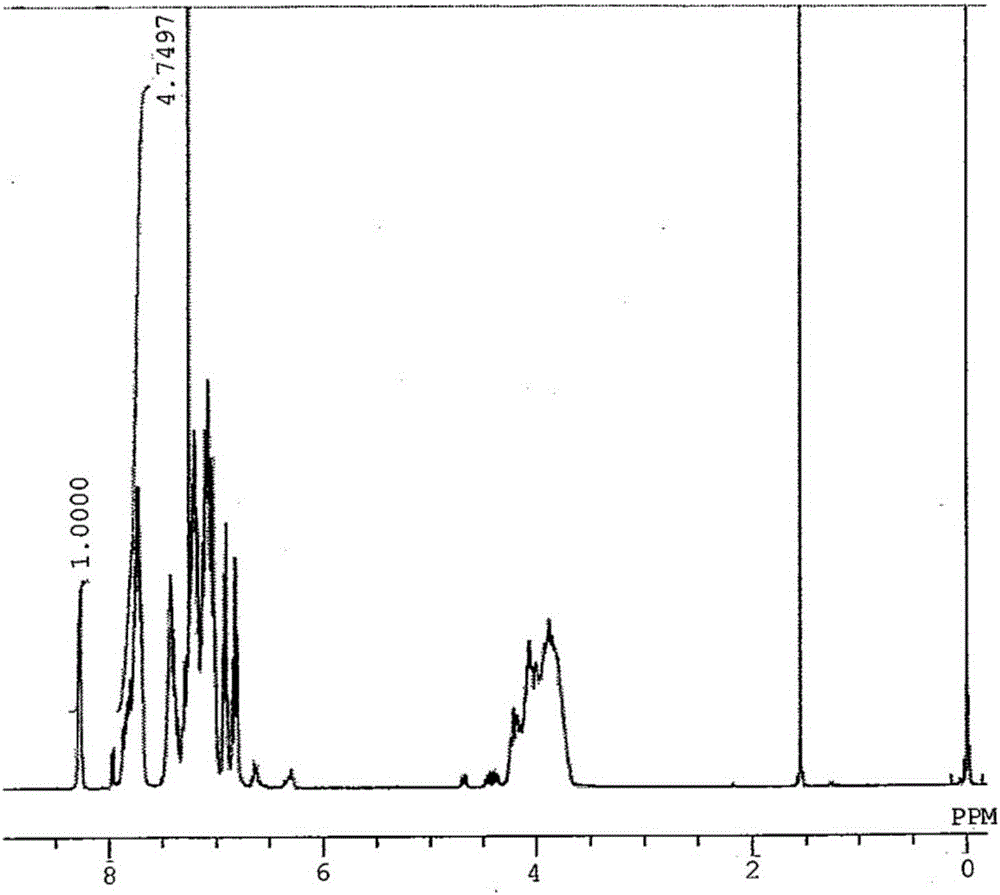

reference example 1

[0144] 374.44 parts by weight of 1,1-bi(2-(2-hydroxyethoxy)naphthalene (hereinafter sometimes abbreviated as "BL-2EO"), 222.79 parts by weight of diphenyl carbonate (DPC), and tetramethyl hydroxide Ammonium 1.82×10 -2 Put the parts by weight into a reaction kettle with a stirrer and a distillation device, heat to 180° C. under a nitrogen atmosphere and normal pressure, and stir for 20 minutes. Then, the degree of reduced pressure was adjusted to 20 to 30 kPa over 20 minutes, and the temperature was raised to 260° C. at a rate of 60° C. / hr to perform transesterification. Then, the pressure was reduced to 0.13 kPa or less over 120 minutes while maintaining the temperature at 260° C., and a polymerization reaction was performed under stirring for 1 hour at 260° C. and 0.13 kPa or less.

Embodiment 1

[0146] BL-2EO was 355.72 parts by weight, 10,10-bis(4-hydroxyphenyl)anthrone (hereinafter sometimes abbreviated as "BP-ANT") was 18.92 parts by weight, DPC was 222.79 g, Polymerization was carried out in the same manner as in Reference Example 1 except that the reaction time under conditions of 260° C. and 0.13 kPa or less was 0.5 hour.

[0147] The polycarbonate has a molar ratio of BL-2EO and BP-ANT of 95:5, a specific viscosity of 0.260, and a Tg of 123°C.

[0148] After vacuum-drying the polycarbonate produced at 123° C. for 4 hours, add 0.050% of bis(2,4-dicumylphenyl) pentaerythritol diphosphite based on the weight of the obtained polycarbonate composition , 0.10% of pentaerythritol tetrastearate was pelletized using a φ30 mm single-screw extruder with a vent. The heat and humidity resistance was good, and the specific viscosity retention rate after the heat and humidity test was 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com