Green plum enzyme and production process thereof

A greengage enzyme and greengage technology, applied in the direction of food science, etc., can solve the problems of reducing the absorption of nutrients, reducing the health care value of enzymes, and easily producing nitrite, etc., to achieve increased sugar content, stable quality, shortened time and product development cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

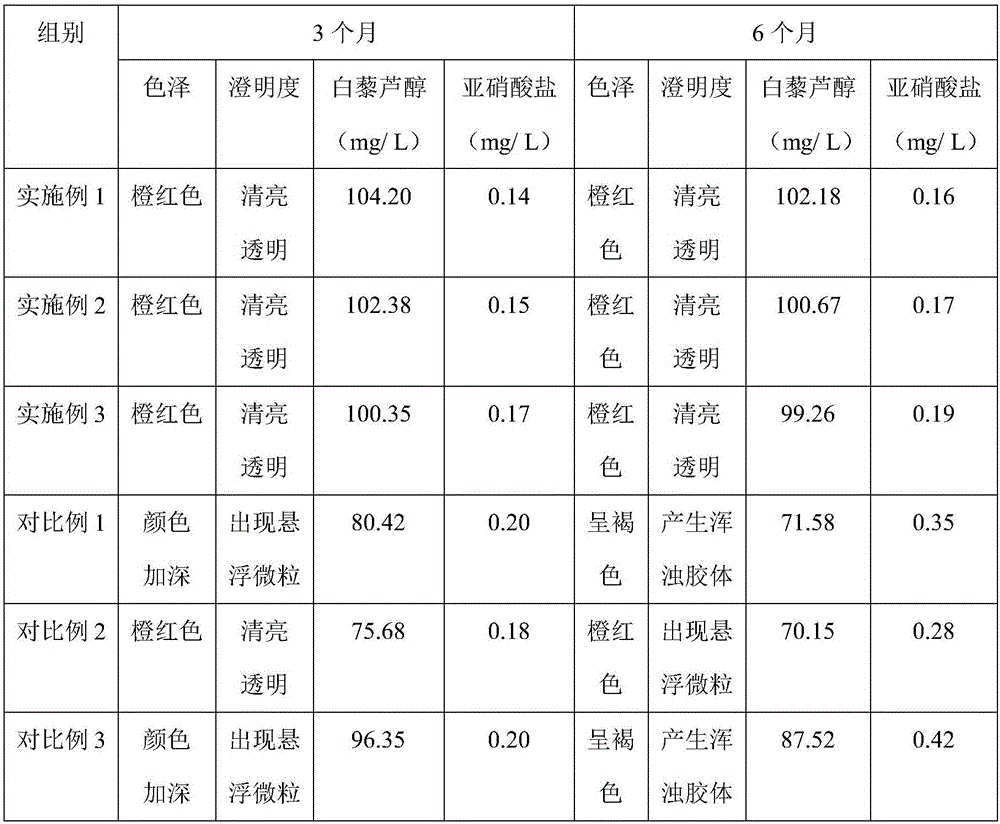

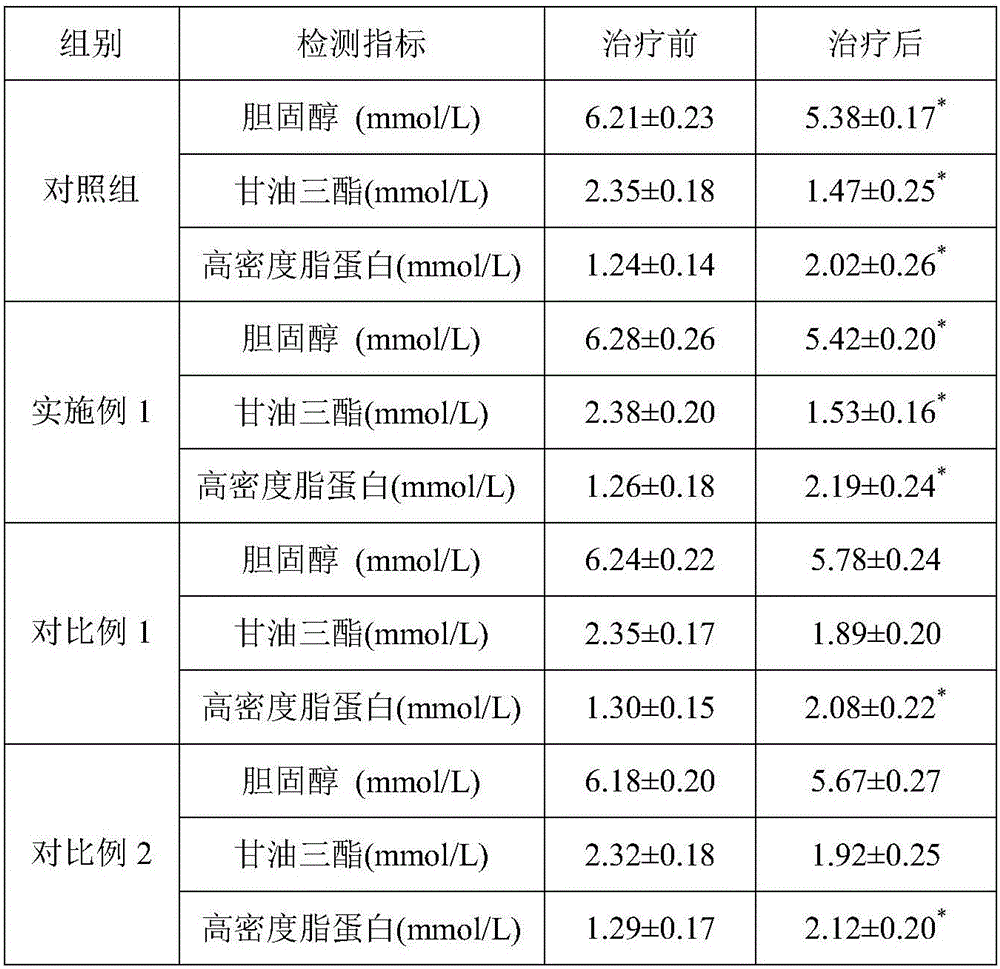

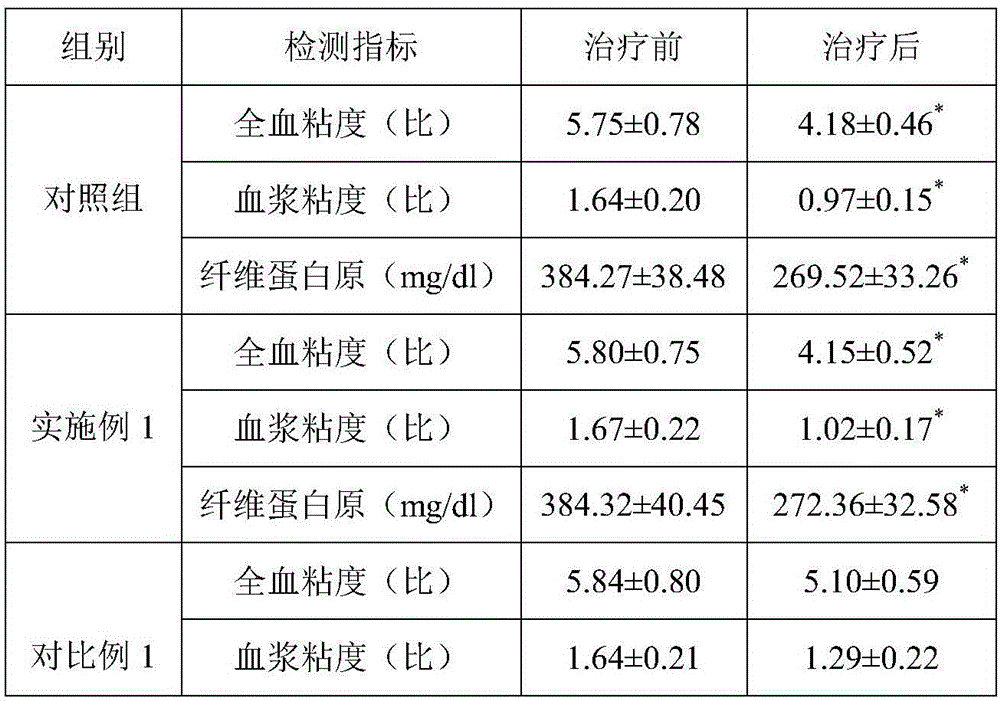

Examples

Embodiment 1

[0031] Example 1 of the present invention green plum enzyme comprises the following preparation raw materials in percentage by weight: green plum 25%, grape 15%, cranberry 15%, longan meat 10%, mulberry 10%, wheat germ powder 15%, polylysine 4 % and ascorbic acid 6%.

[0032] Preparation:

[0033] (1) Take grapes, cranberries, longan meat, and mulberries, place them at -10°C for 12 hours, then raise the temperature to 4°C, place them for 12 hours, and repeat this 3 times for later use;

[0034] (2) Take the greengage, wash it, blanch it in boiling water for 3 minutes, remove the core after letting it cool, cut the pulp and peel into small pieces, soak in ice water at 4°C for 5 days, change the water 3 times a day, and then put the greengage Mix with the grapes, cranberries, longan meat, and mulberry processed in step (1), add water at a ratio of 1:10 according to the material-to-liquid ratio, and homogenize to obtain a slurry, and add a compound enzyme to the slurry to obtain...

Embodiment 2

[0039]Example 2 of the present invention green plum enzyme includes the following preparation raw materials in percentage by weight: green plum 20%, grape 20%, cranberry 10%, longan meat 10%, mulberry 15%, wheat germ powder 15%, polylysine 5% % and ascorbic acid 5%.

[0040] Preparation:

[0041] (1) Take grapes, cranberries, longan meat, and mulberries, place them at -10°C for 12 hours, then raise the temperature to 4°C, place them for 12 hours, and repeat this 3 times for later use;

[0042] (2) Take the greengage, wash it, scald it in boiling water for 5 minutes, remove the core after letting it cool, cut the pulp and peel into small pieces, soak it in 4°C ice water for 3 days, change the water twice a day, and then put the greengage Mix with the grapes, cranberries, longan meat, and mulberry treated in step (1), add water at a ratio of 1:8 according to the material-to-liquid ratio, and homogenize to obtain a slurry, and add a compound enzyme to the slurry, and the Said c...

Embodiment 3

[0047] Example 3 of the present invention green plum enzyme comprises the following preparation raw materials in percentage by weight: green plum 15%, grape 20%, cranberry 20%, longan meat 10%, mulberry 10%, wheat germ powder 15%, polylysine 6 % and ascorbic acid 4%.

[0048] Preparation:

[0049] (1) Take grapes, cranberries, longan meat, and mulberries, place them at -10°C for 12 hours, then raise the temperature to 4°C, place them for 12 hours, and repeat this 3 times for later use;

[0050] (2) Take the greengage, wash it, scald it in boiling water for 4 minutes, remove the core after letting it cool, cut the pulp and peel into small pieces, soak it in 4°C ice water for 4 days, change the water 3 times a day, and then put the greengage Mix with the grapes, cranberries, longan meat, and mulberry processed in step (1), add water at a ratio of 1:10 according to the material-to-liquid ratio, and homogenize to obtain a slurry, and add a compound enzyme to the slurry to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com