Preparation method and application of carbon sphere loaded nanoscale zero valent iron composite material

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., to achieve environmental friendliness, easy promotion, and solve the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

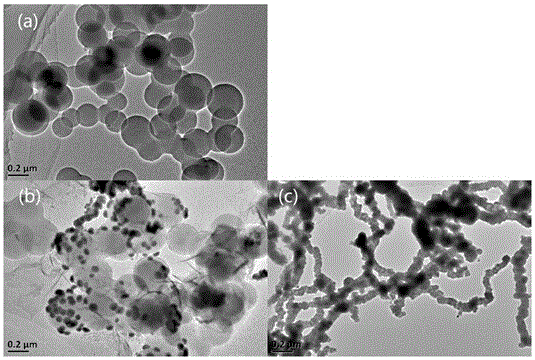

[0026] Example 1: Preparation of nano-zero-valent iron composite material supported by carbon spheres and its transmission electron microscope analysis

[0027] (1) Prepare a glucose solution with a concentration of 0.952 mol / L with deionized water, stir evenly, transfer the prepared solution to a reaction kettle, and react at a temperature of 180°C for 15 hours. After the reaction is completed, naturally cool to room temperature. Centrifuge the obtained black or brown product, rinse it with deionized water and absolute ethanol in turn, filter it to dryness, dry it at 70°C for 4 hours to obtain carbon spheres, and keep it sealed;

[0028] (2) 5.429g FeSO 4 Add 1g of carbon spheres prepared in step (1) into 100mL of ethanol aqueous solution (made by mixing ethanol and water at a volume ratio of 3:7), then add 0.15g of polyethylene glycol, place in Stir in a magnetic stirrer for 3 h to ensure that all Fe 2+ Chelated to the surface of carbon spheres;

[0029] (3) Add 100 mL of...

Embodiment 2

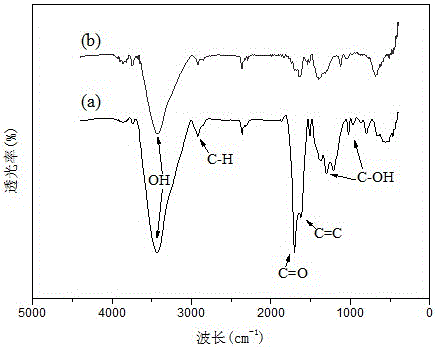

[0032] Example 2: Preparation of nano-zero-valent iron composite material supported by carbon spheres and its Fourier transform infrared analysis

[0033] (1) Prepare a glucose solution with a concentration of 0.463 mol / L with deionized water, stir evenly, transfer the prepared solution to a reaction kettle, and react at a temperature of 160°C for 18 hours. After the reaction is completed, naturally cool to room temperature. Centrifuge the obtained black or brown product, rinse it with deionized water and absolute ethanol in sequence, filter it to dryness, dry it at 60°C for 4 hours to obtain carbon spheres, and keep it sealed;

[0034] (2) 1.448g FeCl 3 Add 0.5g of carbon spheres prepared in step (1) into 50mL of ethanol aqueous solution (prepared by mixing ethanol and water at a volume ratio of 1:4), then add 0.1g of polyethylene glycol, and ultrasonically Stir in a magnetic stirrer for 2h to ensure that all Fe 3+ Chelated to the surface of carbon spheres;

[0035] (3) Ad...

Embodiment 3

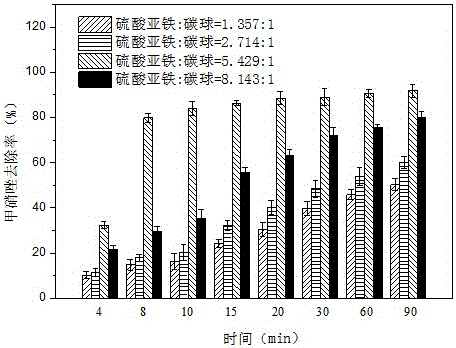

[0038] Example 3: Preparation of carbon sphere-loaded nano-zero-valent iron composites and the effect of different iron amounts on the removal rate

[0039] (1) Prepare a glucose solution with a concentration of 0.444mol / L with deionized water, stir evenly, transfer the prepared solution to a reaction kettle, and react at a temperature of 180°C for 12 hours. After the reaction is completed, cool down to room temperature naturally. Centrifuge the obtained black or brown product, rinse it with deionized water and absolute ethanol in turn, filter it to dryness, dry it at 50°C for 4 hours to obtain carbon spheres, and keep it sealed;

[0040] (2) 1.357g, 2.714g, 5.429g, 8.143g FeSO 4 Add 1g of carbon spheres prepared in step (1) into 100mL of ethanol aqueous solution (prepared by mixing ethanol and water at a ratio of 1:1 by volume), to obtain 4 mixtures of different proportions, and then add 0.1g of Polyethylene glycol, placed in a magnetic stirrer after sonication and stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com