Silk fibroins with different degradation rates and use thereof

A technology of silk fibroin and degradation speed, applied in the field of biomedical materials, can solve the problems of nerve growth without support, complete repair, inflammatory response, etc., achieve non-toxic mechanical properties, promote nerve damage repair, and promote axis The effect of outgrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of the natural silk fiber of desericin

[0032] The electronic balance weighs 40-50g of natural silk fiber wrapped with sericin, and puts it into a stainless steel container of about 5L. Then, take 10.18g of anhydrous sodium carbonate and pour it into a container, pour 2000ml of triple distilled water (about 0.5% sodium carbonate alkaline solution), stir it fully with a glass rod to make it completely dissolve, press the floating silk with a glass rod The fibers are mostly submerged in the sodium carbonate solution. Then, heat it on the induction cooker until it boils, stir the silk with a glass rod, start timing from boiling, cook for about 30 minutes, and stir it properly with a glass rod during this period to make the silk fiber cook evenly. After cooking, pour off the sodium carbonate solution and wash twice with triple distilled water to expose the silk fibroin and increase the whiteness. In order to fully remove the sericin, carry o...

Embodiment 2

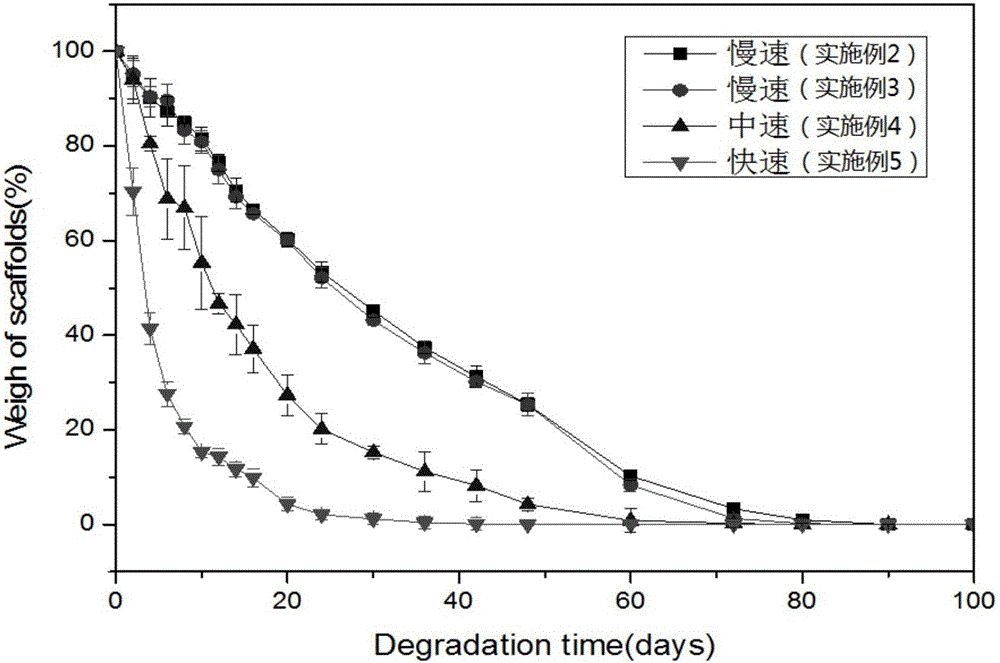

[0033] Embodiment 2: the preparation of slowly degrading silk fibroin

[0034] Weigh 40.45g of lithium bromide and pour it into a 50ml centrifuge tube, add triple distilled water to make it up to 50ml, after fully dissolving, add it to a 100ml beaker under stirring conditions, and add 2.5g of Example 1 at a mass volume ratio of 1:20 to obtain The silk fibroin protein (adding in several times), after adding completely, hydrolyze and stir under the conditions in Table 1, and stand still at room temperature for 30min. Then, dialysis (molecular weight cut off: 12000-14000) was performed for 3 days.

[0035] Table 1

[0036] Group

Hydrolysis temperature

Hydrolysis time

1

25℃

360min

2

70℃

10min

3

50℃

185min

4

70℃

500min

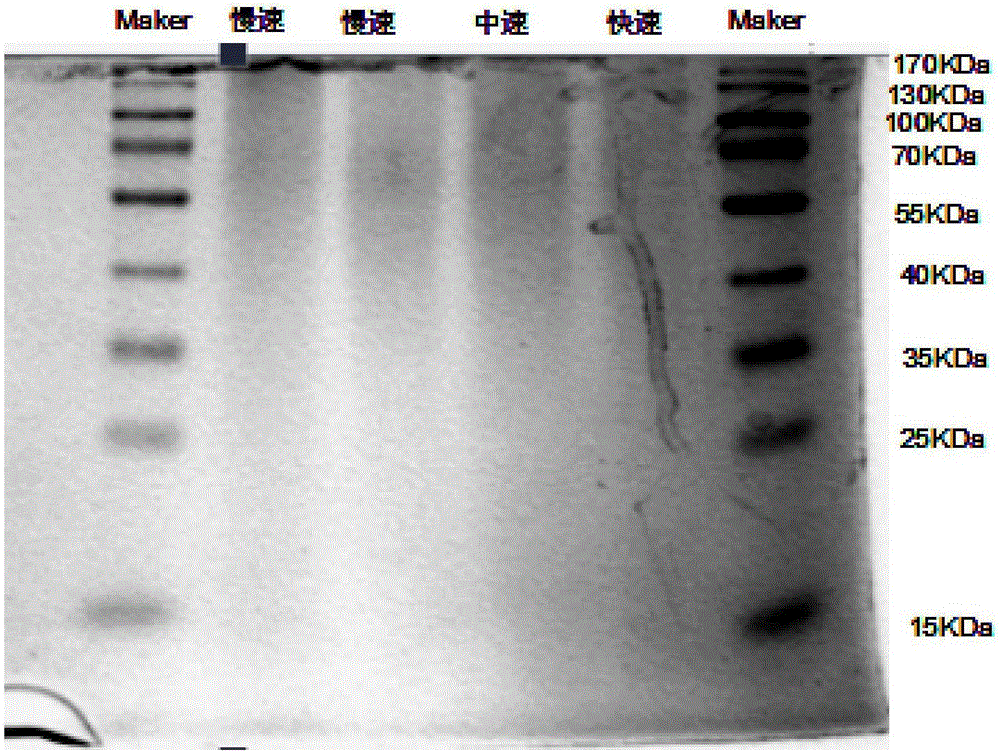

[0037] SDS-PAGE gel electrophoresis was used to test the molecular weight of silk fibroin in groups 1-4. Using 12% SDS-PAGE separating gel (Milli-Q water, 2ml; 30% Acr-Bis (29:1), 4ml; 1M ...

Embodiment 3

[0039] Embodiment 3: the preparation of slowly degrading silk fibroin

[0040] Weigh 37g of anhydrous calcium chloride, put it into a 250ml beaker, add 48ml of triple distilled water to dissolve all the calcium chloride, and heat the water bath to 75-80°C. Then, add 38.78ml of absolute ethanol, add the silk fibroin protein prepared in Example 1 according to the mass volume ratio of 1:20 (adding in several times), continue to stir at this temperature for 10-60min after adding completely (Table 2), Then let cool at room temperature, and perform dialysis (molecular weight cut-off: 12000-14000) for 3 days.

[0041] Table 2

[0042] Group

Hydrolysis temperature

Hydrolysis time

1

80℃

10min

2

78℃

30min

3

75℃

60min

[0043] SDS-PAGE gel electrophoresis was used to test the molecular weight of the silk fibroin in groups 1-3. The test results showed that the hydrolyzed silk fibroin with calcium chloride had a molecular weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com