Flame-retardant long-term ultraviolet aging resistant lapped aluminum alloy power cable

A technology of power cables and aluminum alloys, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems affecting the service life of aluminum alloy power cables, cracking and deformation of the cable surface, etc., to improve long-term UV aging resistance, long service life, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

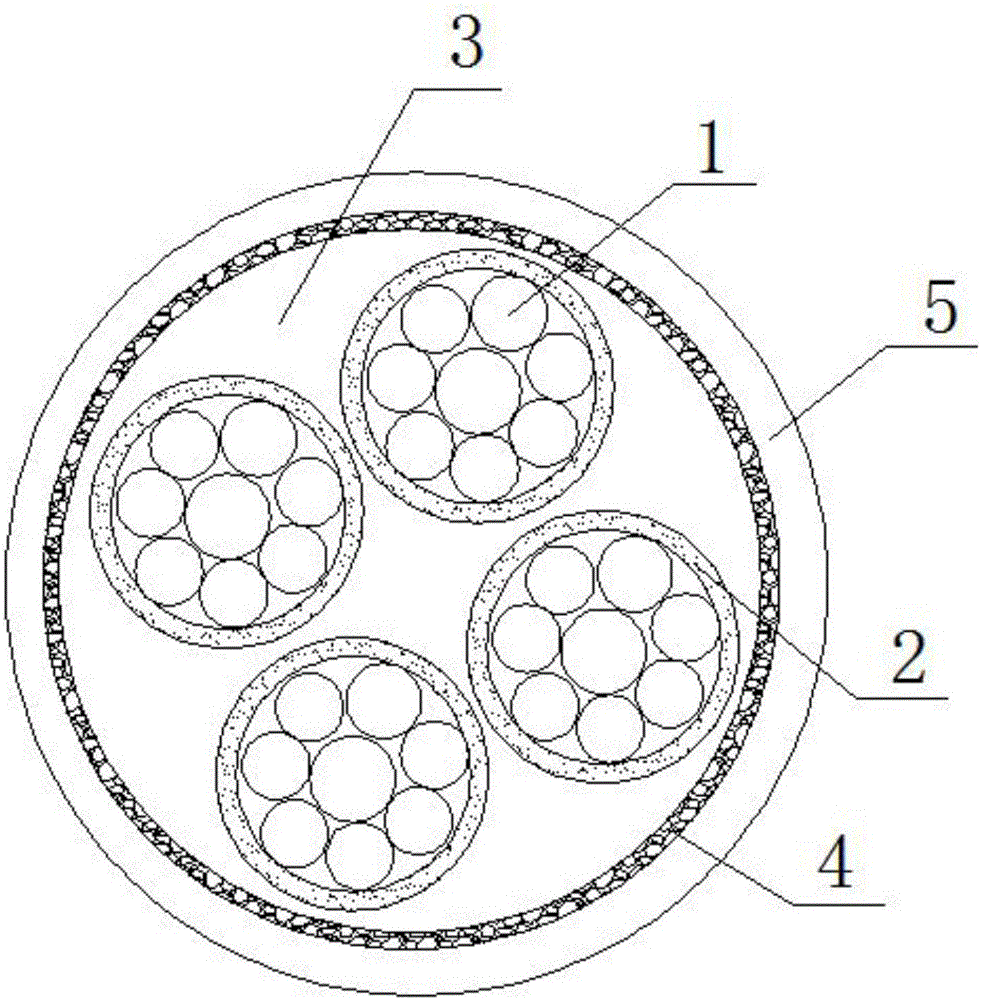

[0030] Such as figure 1 A flame-retardant and long-term UV-resistant wrapped aluminum alloy power cable is shown, including an insulated core composed of an aluminum alloy conductor 1 and an insulating layer 2 (cross-linked polyethylene), and a filler (3 glass fiber cords) , refractory mica tape around the cladding 4 and the PVC sheath 5, in parts by weight, the PVC sheath is made by mixing the following components: 100 parts of PVC resin, 15 parts of EPDM rubber, 10 parts of heat-resistant enhancer 5 parts of polyisobutylene, 20 parts of calcined clay, 1 part of stearic acid, 10 parts of paraffin oil, 1 part of heat stabilizer (dimethyl tin chloride), 1 part of light stabilizer (Tinuvin 622), antioxidant (Antioxidant 1010, Antioxidant 1076, Antioxidant 168) 1 part, toughening agent 5 parts, UV protective agent 0.5 part, molybdenum trioxide 2 parts.

[0031] The heat-resistant enhancer is obtained by modifying the mixture of nano-titanium dioxide and attapulgite, wherein the ...

Embodiment 2

[0040] Such as figure 1 A flame-retardant and long-term UV-resistant wrapped aluminum alloy power cable is shown, including an insulated core composed of an aluminum alloy conductor 1 and an insulating layer 2 (cross-linked polyethylene), and a filler (3 glass fiber cords) , refractory mica tape around the cladding 4 and the PVC sheath 5, in parts by weight, the PVC sheath is made by mixing the following components: 100 parts of PVC resin, 20 parts of EPDM rubber, 15 parts of heat-resistant enhancer 10 parts of polyisobutylene, 30 parts of calcined clay, 3 parts of stearic acid, 15 parts of paraffin oil, 2 parts of heat stabilizer (tin mercaptide), 3 parts of light stabilizer (Tinuvin 770), antioxidant ( Antioxidant 1076) 2 parts, toughening agent 8 parts, UV protective agent 1 part, molybdenum trioxide 4 parts.

[0041] The heat-resistant enhancer is obtained by modifying the mixture of nano-titanium dioxide and attapulgite, wherein the mass ratio of nano-titanium dioxide to...

Embodiment 3

[0050] Such as figure 1 A flame-retardant and long-term UV-resistant wrapped aluminum alloy power cable is shown, including an insulated core composed of an aluminum alloy conductor 1 and an insulating layer 2 (cross-linked polyethylene), and a filler (3 glass fiber cords) , refractory mica tape around the cladding 4 and the PVC sheath 5, by weight, the PVC sheath is made by mixing the following components: 100 parts of PVC resin, 18 parts of EPDM rubber, 12 parts of heat-resistant enhancer 8 parts of polyisobutylene, 25 parts of calcined clay, 2 parts of stearic acid, 12 parts of paraffin oil, 1-2 parts of heat stabilizer (dibutyltin maleate), 1-3 parts of light stabilizer (Tinuvin 770), 1.5 parts of antioxidant (antioxidant 168), 7 parts of toughening agent, 0.8 part of UV protection agent, 3 parts of molybdenum trioxide.

[0051] The heat-resistant enhancer is obtained by modifying the mixture of nano-titanium dioxide and attapulgite, wherein the mass ratio of nano-titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com