Efficient and environment-friendly coal and preparation method thereof

A manufacturing method and an environmentally friendly technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of inability to produce colloids, high degree of metamorphism, and difficulty in coking and blending coal ingredients, and achieve increased calorific value, reduced waste residue, The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

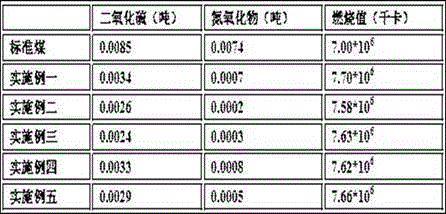

Examples

Embodiment 1

[0043] An environment-friendly high-efficiency carbon is prepared from the following raw materials in parts by weight: 100 parts of single-species coal, 11 parts of asphalt, 9 parts of solid binder, 15 parts of soda ash, 13 parts of gypsum and 10 parts of sodium humate.

[0044] The specific preparation method is as follows:

[0045] Mix the raw materials according to the above proportions, and grind them; preheat to 130°C, add water, press into a block, and send it to a carbonization furnace for carbonization. The carbonization temperature is 900°C and the carbonization time is 4 hours. Atomize the water so that the smoke generated during the carbonization process is not yellow; out of the furnace, put it in water for rapid cooling.

[0046] The charcoal prepared through the above treatment removes most of the harmful substances and reduces the sulfur dioxide produced after combustion.

Embodiment 2

[0048] An environment-friendly high-efficiency carbon is prepared from the following raw materials in parts by weight: 100 parts of single-species coal, 11 parts of asphalt, 9 parts of solid binder, 15 parts of soda ash, 13 parts of gypsum and 10 parts of sodium humate.

[0049] The specific preparation method is as follows:

[0050] Mix the raw materials according to the above proportions, and grind them; preheat to 130°C, add water, press into blocks, and send them to a carbonization furnace for carbonization. The carbonization temperature is 1100°C and the carbonization time is 8 hours. Atomize the water so that the smoke generated during the conversation is not yellow; take it out of the oven, put it in water for rapid cooling after it is out of the oven.

[0051] The charcoal prepared through the above treatment removes most of the harmful substances and reduces the sulfur dioxide produced after combustion.

[0052] Compared with Example 1, using the same formula prolong...

Embodiment 3

[0054] An environment-friendly high-efficiency charcoal is prepared from the following raw materials in parts by weight: 100 parts of single-variety coal, 12 parts of asphalt, 8 parts of solid binder, 21 parts of soda ash, 10 parts of gypsum and 10 parts of sodium humate.

[0055] The specific preparation method is as follows:

[0056] Mix the raw materials according to the above proportions, and grind them; preheat to 130°C, add water, press into a block, and send it to a carbonization furnace for carbonization. The carbonization temperature is 900°C and the carbonization time is 4 hours. Atomize the water so that the smoke generated during the carbonization process is not yellow; out of the furnace, put it in water for rapid cooling.

[0057] Compared with Embodiment 1, the method of this embodiment is the same; the proportion of soda ash is larger, and the emission of sulfur dioxide and nitrogen oxides produced after combustion is less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com