A kind of green trichoderma spore powder dyeing method of silk fabric and wool fabric

A technology of Trichoderma viride and a dyeing method, which is applied in the field of textile dyeing and finishing, can solve the problems that the application in the field of textile dyeing is rarely seen in literature, etc., and can overcome relatively poor color fastness, strong environmental compatibility, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of culture medium and staining solution.

[0043] 1 Experimental materials

[0044] 1.1 Strains

[0045] Trichoderma viride (GIM3.141) was purchased from Guangdong Microbial Culture Collection Center (GIMCC).

[0046] 1.2 Materials and Drugs

[0047] Potatoes, dextrose, dipotassium phosphate, magnesium sulfate heptahydrate, sodium hydroxide, hydrochloric acid, deionized water, and sterile water.

[0048] 2 Experimental Instruments

[0049]XSP-3CB biological microscope, purchased from Shanghai No. 1 Optical Instrument Factory; Shuangha brand YX280 portable stainless steel pressure sterilizer, purchased from Shanghai Sanshen Medical Instrument Co., Ltd.; DHP-9162 constant temperature incubator, purchased from Shanghai Heheng Instrument Equipment Co., Ltd.; HR40-Ⅱ-A2 biological safety cabinet, purchased from Qingdao Haier Special Electric Co., Ltd.; centrifuge, purchased from Yancheng Kite Experimental Instrument Co., Ltd.; SHZ-D (Ⅲ) circulati...

Embodiment 2

[0057] Embodiment two: Utilize dyeing liquid to dye silk fabric and woolen fabric.

[0058] 1 Experimental materials

[0059] The dyeing solution prepared according to the method described in Example 1;

[0060] 11206 silk power spinning (23% degumming rate, 43 g / m 2 );

[0061] Standard fleece lining.

[0062] 2 Experimental Instruments

[0063] UB-10 pH meter was purchased from Denver Instrument Company; XW-ZDR-25*12 low-noise oscillating dyeing machine was purchased from Jingjiang Xinwang Dyeing and Finishing Equipment Factory; TU-19000 UV-visible spectrophotometer was purchased from Beijing Spectrum Analytical General Instrument Co., Ltd.; UltraScan XE color measuring instrument, purchased from HunterLab Company of the United States; Y571B Rubbing Color Fastness Tester, purchased from Nantong Hongda Experimental Instrument Co., Ltd.; SW-12A Washing Color Fastness Tester, purchased from Wuxi Textile Instrument Factory.

[0064] 3 Experimental methods

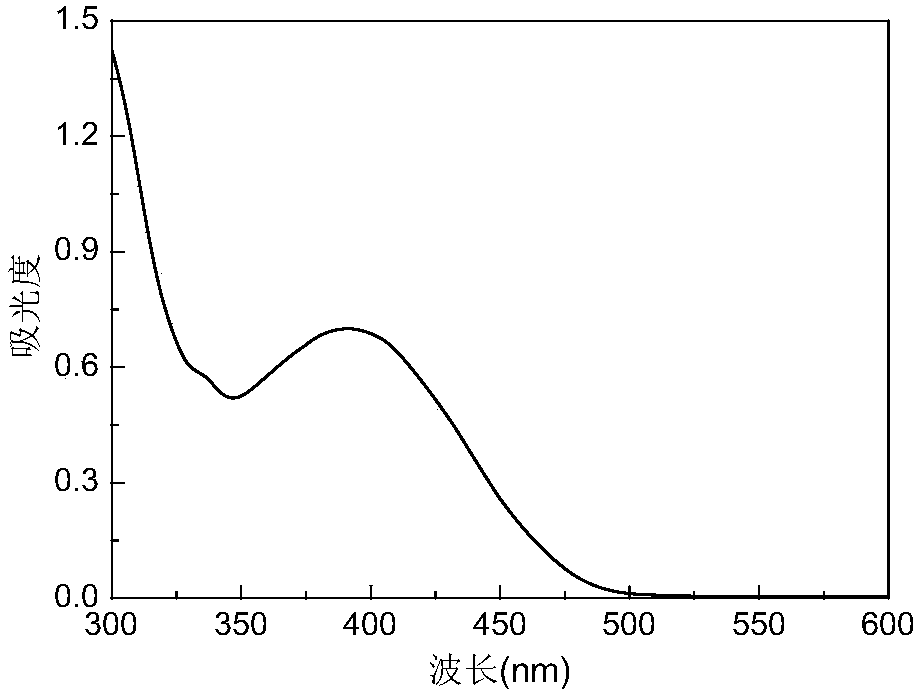

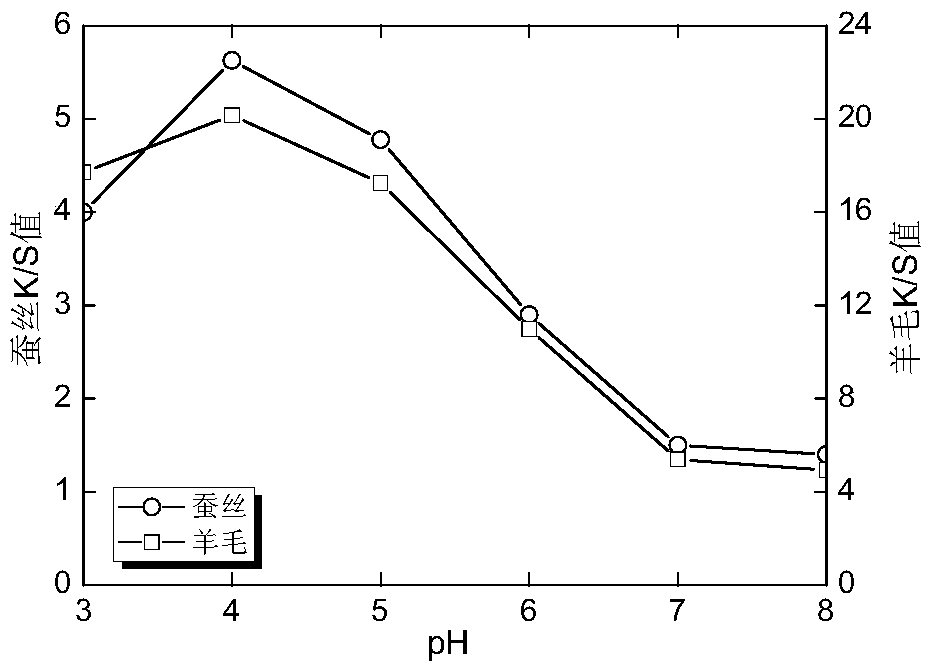

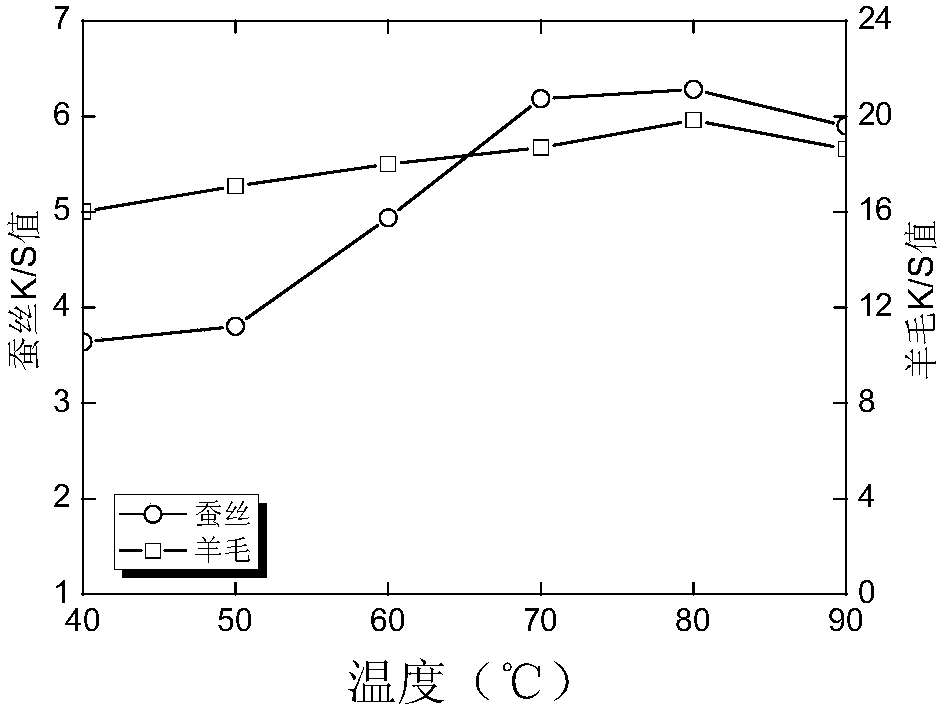

[0065] 3.1 Dye...

Embodiment 3

[0095] Embodiment three: investigate the color fastness of dyed fabric.

[0096] The silk fabric dyed in Example 2 is investigated from two aspects of soaping fastness (discoloration, cotton staining, silk staining, felt) and rubbing fastness (dry rubbing, wet rubbing), wherein the color fastness to soaping is according to The test method recorded in GB / T 3921-2008 "Textile Color Fastness Test to Soaping Color Fastness" is carried out, and the color fastness to rubbing is in accordance with GB / T 3920-2008 "Textile Color Fastness Test to Color Fastness to Rubbing" The test method recorded in , and the color fastness to light is carried out according to the test method recorded in GB / T 8427-2008 "Textile Color Fastness Tests Color Fastness to Light", and the results are shown in Table 5.

[0097]

[0098] As can be seen from Table 5, the color fastness of wool fabrics dyed with Trichoderma viridans spore powder is slightly better than that of silk fabrics dyed on it, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com