Ionic-liquid-gel-electrolyte-based quasi-solid flexible self-powered ZnO-based ultraviolet detector and preparation method thereof

A gel electrolyte and ultraviolet detector technology, which is applied in semiconductor devices, circuits, electrical components, etc., can solve the problems that hinder the long-term continuous operation of the detector, and the electrolyte is volatile, so as to achieve easy large-scale production and good charge transmission performance , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

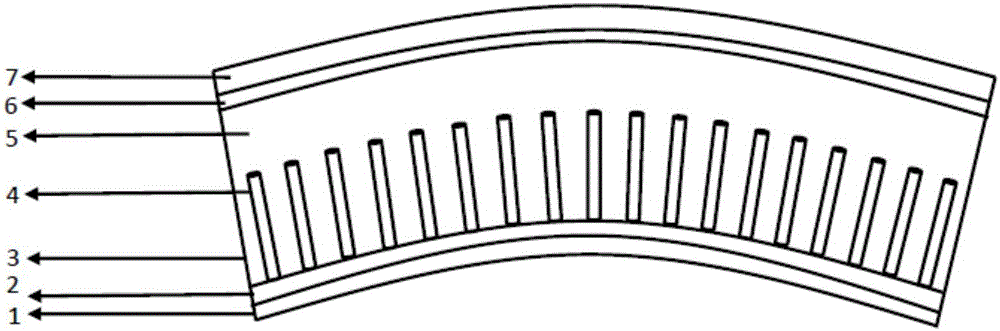

[0026] 1) Put the cleaned PET substrate coated with ITO conductive film into the laser pulse deposition equipment, use the ZnO ceramic target as the target, adjust the growth temperature to 60 ° C, O 2 The pressure is 1Pa, and the growth thickness is a ZnO seed layer of 50nm; then put into the hydrothermal reaction kettle, with zinc acetate dihydrate and hexamethylenetetramine as the source, the zinc acetate dihydrate and hexamethylenetetramine The molar ratio is 1:1, and the working electrode is prepared by growing a ZnO nanoarray with a length of 1.5 μm on the ZnO seed layer at 80°C for 4 hours;

[0027] 2) Dissolve 50 mg of 1-methyl-3-propyl imidazolium iodide in 2 mL of hexanitrile, stir for 10 min, then add 0.1 g of potassium iodide and stir until dissolved, finally add 0.5 g of polyethylene oxide, and stir for 12 h to prepare Ionic liquid gel electrolyte;

[0028] 3) Put the cleaned PET flexible substrate into the electron beam evaporation equipment, use metal Pt as the...

Embodiment 2

[0032] 1) Put the cleaned PET substrate coated with ITO conductive film into the laser pulse deposition equipment, use ZnO ceramic target as the target material, adjust the growth temperature to 30°C, O 2 Pressure is 2Pa, and the growth thickness is the ZnO seed crystal layer of 20nm; Put into hydrothermal reactor then, be source with dihydrate zinc acetate and hexamethylenetetramine, the dihydrate zinc acetate and hexamethylenetetramine The molar ratio is 1:1, and the working electrode is prepared by growing a ZnO nanoarray with a length of 3 μm on the ZnO seed layer at 85°C for 7 hours;

[0033] 2) Dissolve 50 mg of 1-methyl-3-propylimidazolium iodide in 3 mL of hexanitrile, stir for 10 min, then add 0.2 g of potassium iodide and stir until dissolved, finally add 1 g of polyethylene oxide, and stir for 12 h to prepare an ionic liquid gel electrolyte;

[0034] 3) Put the cleaned PET flexible substrate into the electron beam evaporation equipment, use metal Pt as the evaporat...

Embodiment 3

[0038] 1) Put the cleaned PET substrate coated with ITO conductive film into the laser pulse deposition equipment, use the ZnO ceramic target as the target material, adjust the growth temperature to 50°C, O 2 The pressure is 1Pa, and the growth thickness is a ZnO seed layer of 80nm; then put into a hydrothermal reaction kettle, with zinc acetate dihydrate and hexamethylenetetramine as the source, the zinc acetate dihydrate and hexamethylenetetramine The molar ratio is 1:1, the temperature is kept at 85°C for 5h, and the ZnO nanoarray with a length of 2.5 μm is grown on the ZnO seed layer to prepare the working electrode;

[0039] 2) Dissolve 50 mg of 1-methyl-3-propyl imidazolium iodide in 3 mL of hexanitrile, stir for 10 min, then add 0.2 g of potassium iodide and stir until dissolved, finally add 2 g of polyethylene oxide, and stir for 12 h to prepare ions liquid gel electrolyte;

[0040] 3) Put the cleaned PET flexible substrate into the electron beam evaporation equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com