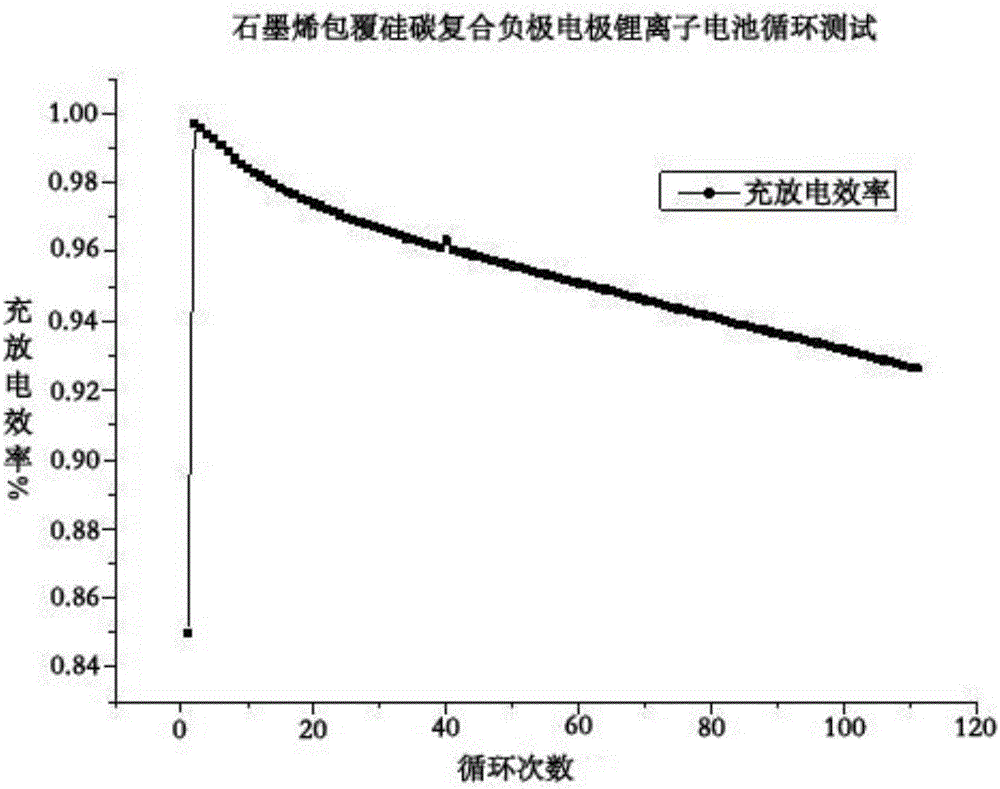

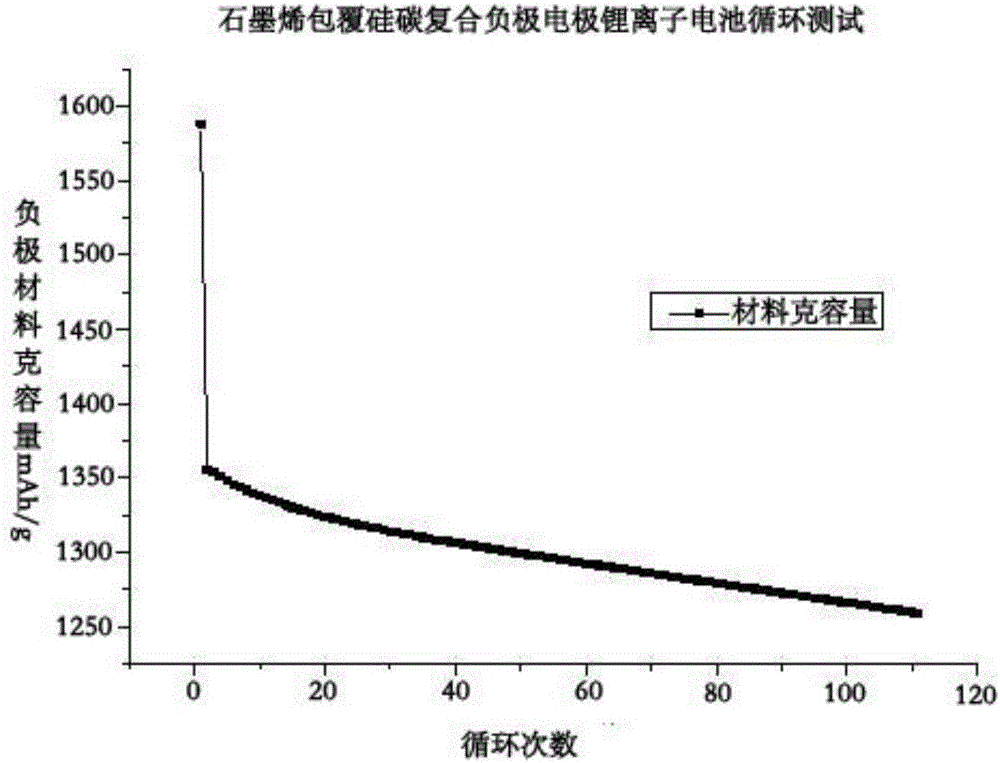

Preparation method of graphene-coated silicon-carbon composite anode material and lithium ion battery

A graphene-coated, silicon-carbon composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as rapid capacity decay, and achieve the effects of reduced expansion rate, excellent electrical conductivity, and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of a graphene-coated silicon-carbon composite negative electrode, comprising the steps of:

[0028] Step 1) Prepare a graphene-coated silicon-carbon composite negative electrode slurry by fully and effectively dispersing the nano-silicon material, graphite, graphene, graphite oxide, organic polymer and solvent;

[0029] Among them, the mass fraction of nano-silicon material accounts for 30%-90%, the mass fraction of graphite and graphite oxide accounts for 0%-30%, and the mass fraction of graphene accounts for 2%-30%. The mass fraction of the substance accounts for 5%-30%, and the balance is a solvent;

[0030] Step 2) coating the silicon-carbon composite negative electrode slurry coated with graphene on the metal current collector;

[0031] Step 3) After the coated negative electrode is calcined at high temperature and rapidly cooled in a short period of time, the graphene-coated silicon-carbon composite negative electrode finally used for lithium...

Embodiment

[0043] A preparation method of a graphene-coated silicon-carbon composite negative electrode, comprising the steps of:

[0044] Step 1) Prepare graphene-coated silicon-carbon composites by ultrasonically dispersing nano-silicon materials, graphite, S-substituted graphene, graphite oxide, polyacrylonitrile, and N,N-dimethylformamide with a particle size distribution of 100 nm. Negative electrode slurry, wherein the mass fraction of nano-silicon material accounts for 30%, the mass fraction of graphite and graphite oxide accounts for 5%, the mass fraction of graphene accounts for 20%, and the mass fraction of polyacrylonitrile accounts for 15%. %, the balance is solvent N,N-dimethylformamide;

[0045] Step 2) coating the silicon-carbon composite negative electrode slurry coated with graphene on the copper foil;

[0046] Step 3) Under a helium atmosphere, the negative electrode that has been coated is controlled at a rate of 10° C. / min to control the final temperature of the nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com