Graphene oxide/titanium dioxide nano-needle composite material and preparation method and application thereof

A technology of titanium dioxide and composite materials, which is applied in the field of materials, can solve the problems of low photocatalytic efficiency, small specific surface area, and easy agglomeration, and achieve high photocatalytic efficiency, strong light capture ability, and improved utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

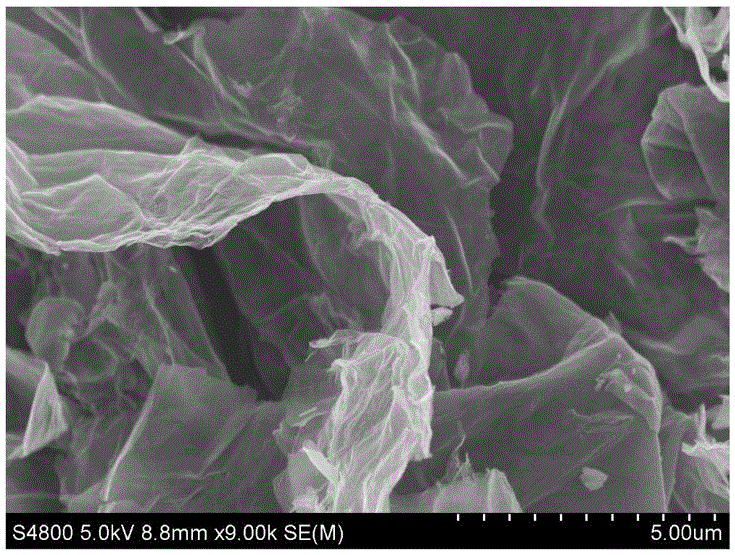

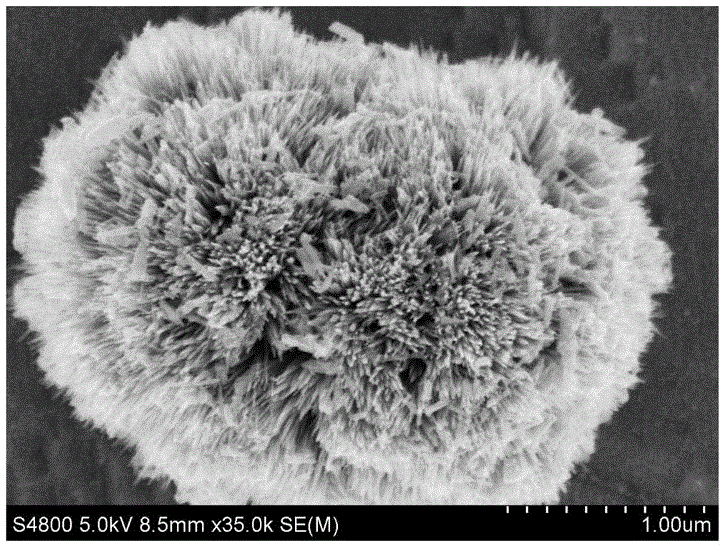

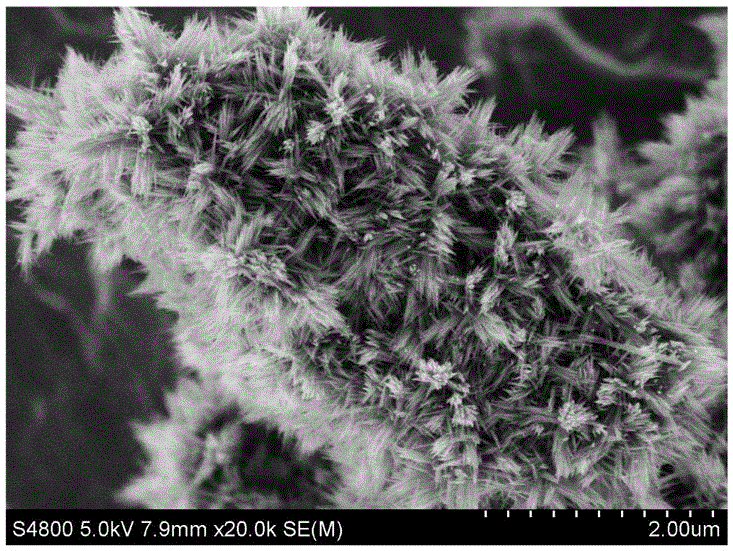

[0033] A graphene oxide / titanium dioxide nanoneedle composite material of the present invention, with graphene oxide as a carrier, titanium dioxide nanoneedles are vertically distributed on the surface of graphene oxide, wherein the titanium dioxide nanoneedles have a diameter of 10nm to 15nm and a length of 400nm to 500nm; The mass ratio of graphene and titanium dioxide nanoneedles is 1:140.8.

[0034] A preparation method of the graphene oxide / titanium dioxide nanoneedle composite material of the above-mentioned present embodiment, comprising the steps of:

[0035] (1) Add 2 mg of graphene oxide into 20 mL of ethylene glycol solution, and disperse it uniformly by ultrasonication for 100 min to prepare a graphene oxide dispersion, wherein the concentration of the graphene oxide dispersion is 0.1 g / L.

[0036] (2) Add 1.0 g of isopropyl titanate to 5 mL of concentrated hydrochloric acid with a mass concentration of 36.5%, and add 15 mL of ultrapure water while stirring to obta...

Embodiment 2

[0043] A graphene oxide / titanium dioxide nanoneedle composite material of the present invention, with graphene oxide as a carrier, titanium dioxide nanoneedles are vertically distributed on the surface of graphene oxide, wherein the titanium dioxide nanoneedles have a diameter of 10nm to 15nm and a length of 400nm to 500nm; The mass ratio of graphene and titanium dioxide nanoneedles is 1:14.08.

[0044] A preparation method of the graphene oxide / titanium dioxide nanoneedle composite material of the above-mentioned present embodiment, comprising the steps of:

[0045] (1) Add 10 mg of graphene oxide into 20 mL of ethylene glycol solution, and disperse it uniformly by ultrasonication for 100 min to prepare a graphene oxide dispersion, wherein the concentration of the graphene oxide dispersion is 0.5 g / L.

[0046] (2) Add 0.5 g of isopropyl titanate to 5 mL of concentrated hydrochloric acid with a mass concentration of 36.5%, and add 15 mL of ultrapure water while stirring to obt...

Embodiment 3

[0051] The application of a graphene oxide / titanium dioxide nanoneedle composite material of the present invention in degrading methylene blue wastewater comprises the following steps:

[0052] Add 20 mg of the graphene oxide / titanium dioxide nanoneedle composite material prepared in Example 1 of the present invention into 50 mL of a methylene blue solution with a concentration of 20 mg / L, mix and disperse evenly, and then simulate sunlight under a 150W high-pressure xenon lamp, and take samples every 10 minutes. 1mL sample was taken out, and after centrifugation, the upper clear layer was taken to measure the absorbance at 654nm by a UV-visible spectrophotometer to determine the residual methylene blue concentration. degradation effect. A blank control was made without adding graphene oxide / titanium dioxide nanoneedle composite material.

[0053] Figure 5 It is the photocatalytic degradation effect diagram of the graphene oxide / titanium dioxide nanoneedle composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com