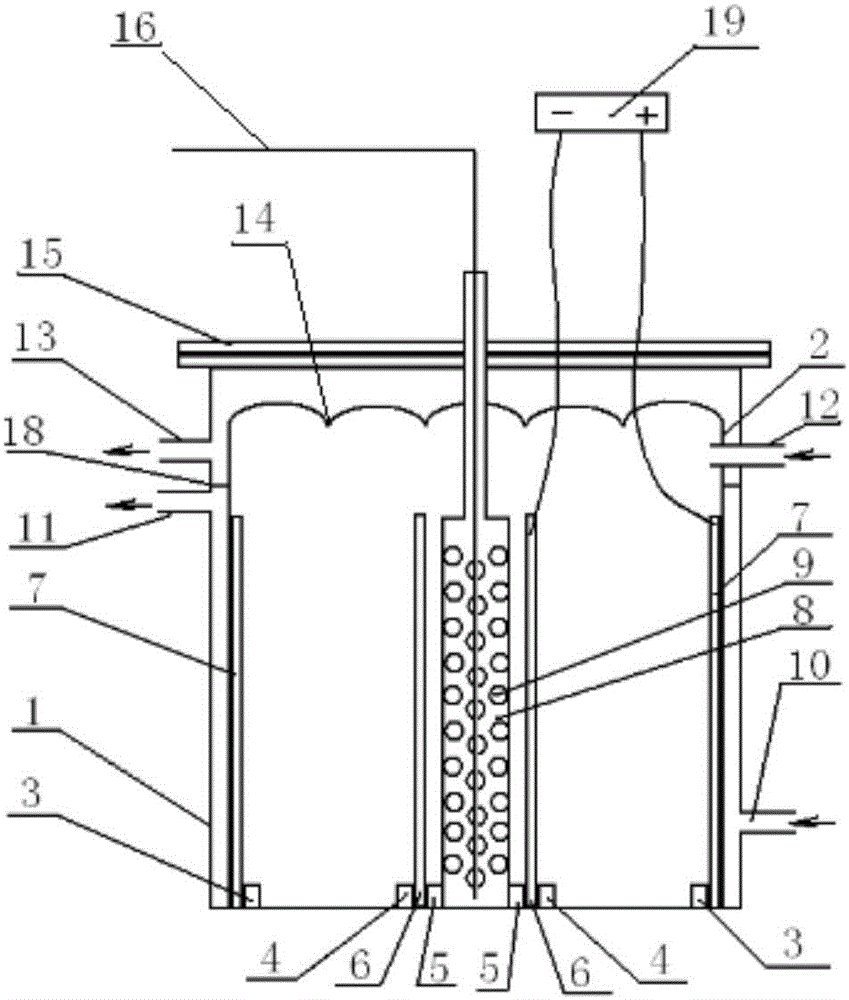

Electrode bio-membrane reactor capable of synchronously removing nitrate and hexavalent chromium

A biofilm reactor and reactor technology, which is applied in electrochemical biocombination treatment, biological treatment device, biological water/sewage treatment, etc., can solve the problem of high operation cost and maintenance cost of ion exchange method, and limit the contact between pollutants and microorganisms. With mixing, membrane separation method membrane is easily contaminated and other problems, to achieve the effect of large biofouling capacity, easy operation and maintenance, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

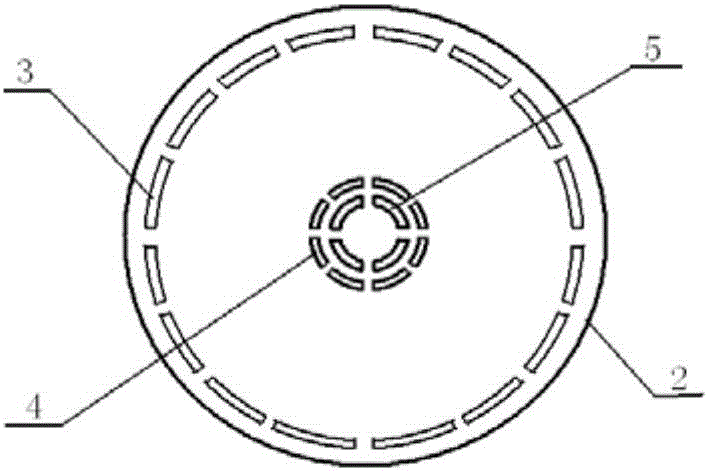

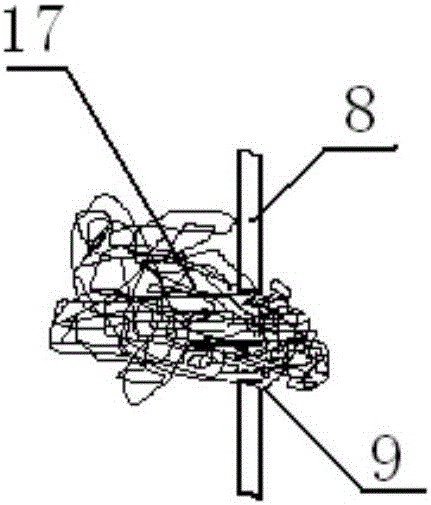

Method used

Image

Examples

Embodiment 1

[0047] The reactor of the present invention is used.

[0048] The concentration of nitrate in artificial water is 50mg / L, and methanol is added as organic carbon source to control C / N to 0.7, pH to 7, and HRT to 8 hours. When the current intensity I is 0, 20, and 50mA, the denitrification effect of the reaction system is the best when the current I=50mA, and neither nitrate nor nitrite is detected in the effluent. When the microcurrent is controlled at 50mA, the dosage of carbon source is gradually reduced, and the C / N is 0.5, which can still have a good nitrate removal effect, but nitrite has begun to accumulate.

[0049]

Embodiment 2

[0051] The reactor of the present invention is used.

[0052] The concentration of hexavalent chromium in the artificially distributed water is 1.0 mg / L, the added organic carbon source (methanol) is 30 mg / L, the pH is 7, and the HRT is 8 hours. When the microcurrent I is 0, 20, 50, 100, and 200mA, when the current intensity is 50mA, the removal effect of Cr(VI) concentration in the reactor effluent is the best, and the removal rate of Cr(VI) reaches more than 95%. After stable operation The removal rate of Cr(VI) can reach 100%.

[0053]

Embodiment 3

[0055] The reactor of the present invention is used.

[0056] The concentration of nitrate in the artificially distributed water is 50mg / L, the concentration of hexavalent chromium in the influent is 1.0mg / L, methanol is added as the organic carbon source to control the reaction system C / N to 0.8, and a buffer solution is added to keep the pH of the influent at about 7. The residence time HRT is 8 hours.

[0057] When the microcurrent I is 0, 20, 50, 100, and 200mA, the effect of synchronous removal of nitrate and chromium salt compound pollution matrix is worse than that of the reactor alone. However, when the current intensity is 50mA, the treatment effect of the reactor is still better, and the removal effect of Cr(VI) and nitrate in the effluent is the best. At the same time, there is no obvious accumulation of nitrite. The removal rates all reached more than 90%.

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com