Silicon nitride combined silicon carbide kiln composite block heat-insulation material and preparation method thereof

A thermal insulation material, a technology of silicon carbide, applied in the field of composite thermal insulation materials, can solve the problems of thermal insulation performance and strength decline of silicon carbide thermal insulation materials, and achieve the effect of good thermal insulation performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

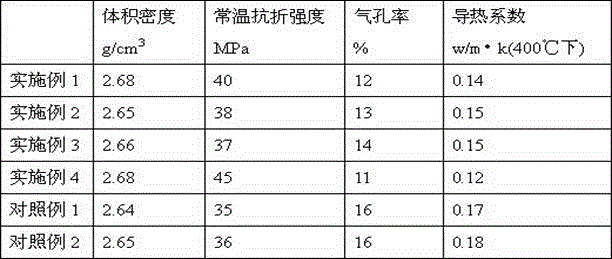

Examples

Embodiment 1

[0033] Prepare the following raw materials in parts by weight: 80 parts of silicon carbide (SiC), silicon nitride (Si 3 N 4 ) 3 parts, aluminum titanate (Al 2 TiO 5 ) 4 parts, potassium titanate whiskers 4 parts, filler particle silica 3 parts, paraffin wax 6 parts, talcum powder 3 parts, cationic surfactant stearyl amino ether lactate 2 parts, anionic surfactant 2- 2 parts of ethylhexyl sulfate, 3 parts of crystalline polyester resin polyethylene terephthalate, 6 parts of organic solvent ethyl acetate.

[0034] The preparation method comprises the steps of:

[0035] Step 1: Mix silicon carbide, aluminum titanate, potassium titanate whiskers, cationic surfactant, crystalline polyester resin, and organic solvent at 80°C for 20 minutes to obtain a mixture of cationic modified particles ;

[0036] In the second step, the silicon nitride, filler particles, paraffin, talcum powder, and anionic surfactant are mixed uniformly at 40°C, and the mixing time is 20 minutes to obtain ...

Embodiment 2

[0041] Prepare the following raw materials in parts by weight: 90 parts of silicon carbide (SiC), silicon nitride (Si 3 N 4 ) 10 parts, aluminum titanate (Al 2 TiO 5 ) 7 parts, potassium titanate whiskers 12 parts, filler particle silica 5 parts, paraffin wax 8 parts, talc powder 5 parts, cationic surfactant stearyl amino ether lactate 4 parts, anionic surfactant 2- 4 parts of ethylhexyl sulfate, 6 parts of crystalline polyester resin polyethylene terephthalate, 12 parts of organic solvent ethyl acetate.

[0042] The preparation method comprises the steps of:

[0043] Step 1: Mix silicon carbide, aluminum titanate, potassium titanate whiskers, cationic surfactant, crystalline polyester resin, and organic solvent at 110°C for 30 minutes to obtain a mixture of cationic modified particles ;

[0044] In the second step, the silicon nitride, filler particles, paraffin, talcum powder, and anionic surfactant are mixed uniformly at 50°C, and the mixing time is 30 minutes to obtai...

Embodiment 3

[0049] Prepare the following raw materials by weight: 85 parts of silicon carbide (SiC), silicon nitride (Si 3 N 4 ) 5 parts, aluminum titanate (Al 2 TiO 5 ) 5 parts, potassium titanate whiskers 5 parts, filler particle silica 4 parts, paraffin wax 7 parts, talcum powder 4 parts, cationic surfactant stearyl amino ether lactate 3 parts, anionic surfactant 2- 3 parts of ethylhexyl sulfate, 4 parts of crystalline polyester resin polyethylene terephthalate, 8 parts of organic solvent ethyl acetate.

[0050] The preparation method comprises the steps of:

[0051] Step 1: Mix silicon carbide, aluminum titanate, potassium titanate whiskers, cationic surfactant, crystalline polyester resin, and organic solvent at 90°C for 25 minutes to obtain a mixture of cationic modified particles ;

[0052] Step 2: Mix silicon nitride, filler particles, paraffin wax, talcum powder, and anionic surfactant at 45°C, and the mixing time is 25 minutes to obtain a mixture of anion-modified particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com