Method and system for refining cyclohexanone and recycling cyclohexanol

A technology of cyclohexanol and cyclohexanone, which is applied in the field of cyclohexanone refining and cyclohexanol recycling, can solve the problem of high reaction activity, achieve the effects of high product purity, reduce material consumption and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

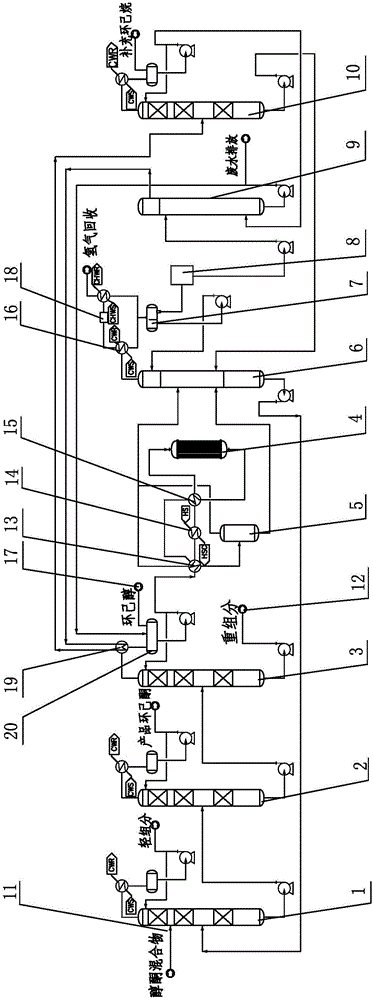

[0031] A method for refining cyclohexanone and recycling cyclohexanol, such as figure 1 As shown, it specifically includes the following steps:

[0032] (1) Send the alcohol and ketone mixture material (crude phenol hydrogenation product) containing cyclohexanone, cyclohexanol, light components and heavy components to the light removal tower 1, and control the number of theoretical plates in the light removal tower 1 to 30 -70 blocks, the top pressure is controlled to be 40-65kpa, the reflux ratio is controlled to be 100-1000, the light impurity components with cyclohexanone content less than 20wt% are extracted from the top of the light removal tower 1, and the light components are extracted from the bottom of the tower Materials with a content of less than 50ppm;

[0033] (2) Send the material with the light component content lower than 50ppm obtained in step (1) into the cyclohexanone product tower 2, and control the theoretical plate number of the cyclohexanone product to...

specific Embodiment 2

[0040] The system used for the purification of cyclohexanone and the recycling method of cyclohexanol in the above specific embodiment one, such as figure 1 As shown, it includes light removal tower 1, cyclohexanone product tower 2, cyclohexanol recovery tower 3, cyclohexanol dehydrogenation reactor 4, gas-liquid separation tank 5, dehydration tower 6, oil-water separator 7, waste water collection tank 8. Cyclohexane extraction tower 9, alcohol and ketone recovery tower 10, the upper end of light removal tower 1 is provided with alcohol and ketone mixture material (phenol hydrogenation crude product) inlet 11, the bottom material outlet of light removal tower 1 and cyclohexanone product The middle material inlet of tower 2 is connected, and the bottom material outlet of cyclohexanone product tower 2 is connected with the middle material inlet of cyclohexanol recovery tower 3, and the tower bottom of cyclohexanol recovery tower 3 is provided with heavy component outlet 12, cyclo...

specific Embodiment 3

[0042] Processing method is with above-mentioned embodiment one, and system equipment is with above-mentioned embodiment two, and its difference is:

[0043] The theoretical plate number of light removal tower 1 is 55, and tower top pressure is 55kpa, and mass reflux ratio is 400;

[0044] The theoretical plate number of cyclohexanone product tower 2 is 55, and tower top pressure is 15 kpa, and mass reflux ratio is 3;

[0045] The theoretical plate number of cyclohexanol recovery tower 3 is 45, and tower top pressure is 20 kpa, and reflux ratio is 1.5;

[0046] The theoretical plate number of hexanaphthene extraction tower 9 is 8, and tower top pressure is 130 kpa;

[0047] The theoretical plate number of alcohol and ketone recovery tower 10 is 40, and tower top pressure is 105 kpa, and mass reflux ratio is 0.8;

[0048] The dehydration tower 6 is a rectification tower with 8 theoretical plates and a pressure at the top of the tower of 120kpa.

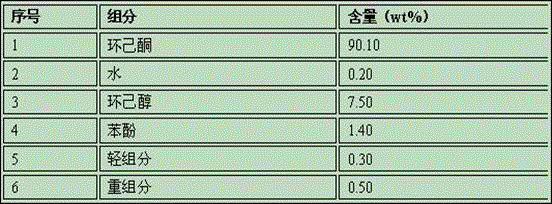

[0049] Among them, the alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com