Method for extracting gentamycin sulfate from gentamicin fermentation broth

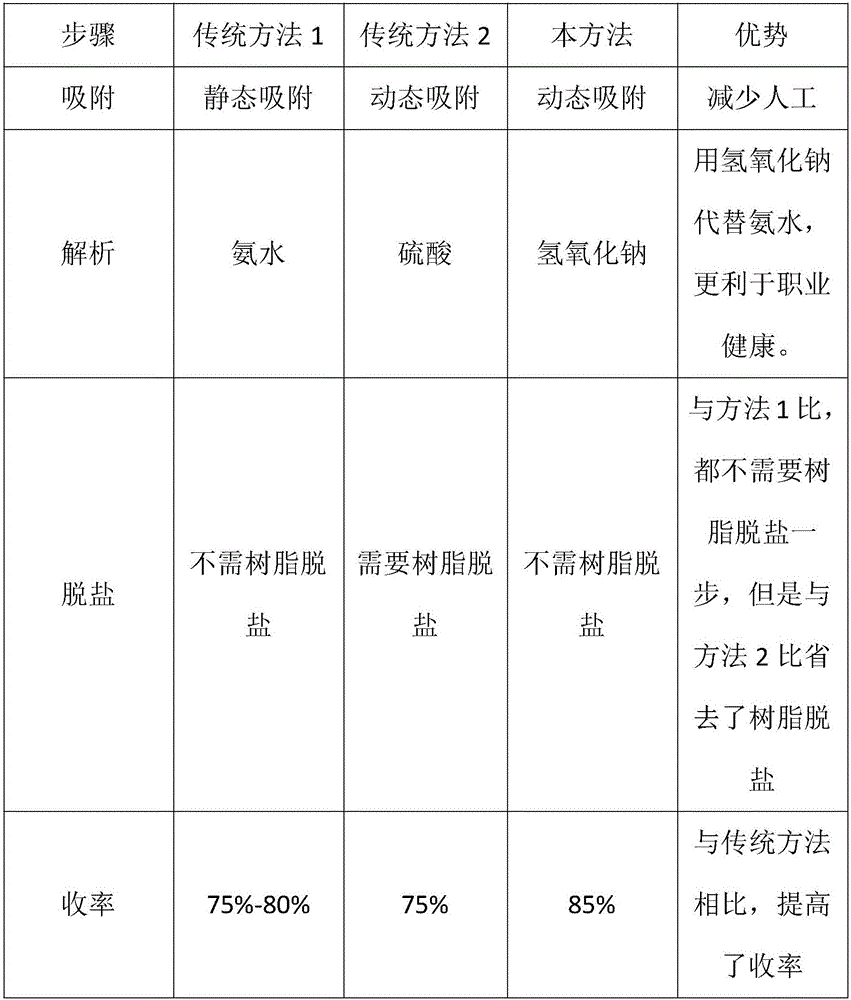

A technology of gentamicin sulfate and gentamicin, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of long steps, cumbersome process, low yield, etc., and achieve low hardness , the effect of reducing costs and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Get gentamicin fermentation liquid 50L, potency 1500U / ml, containing product 0.075 billion. Adjust the pH to 2.0 with sulfuric acid, and filter the acidified solution with a ceramic membrane. The filtrate was adjusted to pH 6.0 with aqueous sodium hydroxide solution to obtain a neutralized solution. Pump the neutralizing solution into the D152 resin column for adsorption at a flow rate of 0.1BV / h. After the adsorption is saturated, pre-wash with 0.01mol / L sodium hydroxide aqueous solution at a flow rate of 0.1BV / h. When the titer is given, the prewashing is considered to be over. After pre-washing, elute with 0.1mol / L sodium hydroxide aqueous solution at a flow rate of 0.1BV / h until the pH of the effluent reaches 11.0, and top-wash with water until the titer is less than 100u / ml. The analytical solution is decolorized with 711 resin, and the decolorized solution is concentrated and desalted with a nanofiltration membrane with a molecular weight of 200. Sulfuric acid...

Embodiment 2

[0031] Gentamicin fermented broth 55L, potency 1450U / ml, product 0.0798 billion. Adjust the pH to 4.0 with sulfuric acid, and filter the acidified solution with a ceramic membrane. The filtrate was adjusted to pH 8.0 with aqueous sodium hydroxide solution to obtain a neutralized solution. Pump the neutralizing solution into the D152 resin column for adsorption at a flow rate of 3.0BV / h. After adsorption saturation, pre-wash with 0.1mol / L sodium hydroxide aqueous solution at a flow rate of 1BV / h. When the titer is given, the prewashing is considered to be over. After pre-washing, use 1.0mol / L sodium hydroxide aqueous solution for elution, the flow rate is 1BV / h until the pH of the effluent reaches 12.0, and top wash with water until the titer is less than 100u / ml. The analytical solution is decolorized with 711 resin, and the decolorized solution is concentrated and desalted with a nanofiltration membrane with a molecular weight of 270. Add sulfuric acid to the concentrated...

Embodiment 3

[0033] Get gentamicin fermentation liquid 60L, potency 1550U / ml, product 0.093 billion. Adjust the pH to 3.0 with sulfuric acid, and filter the acidified solution with a ceramic membrane. The filtrate was adjusted to pH 7.0 with aqueous sodium hydroxide solution to obtain a neutralized solution. Pump the neutralizing solution into the D152 resin column for adsorption at a flow rate of 1.0BV / h. After adsorption saturation, pre-wash with 0.05mol / L sodium hydroxide aqueous solution at a flow rate of 0.5BV / h. When the titer is given, the prewashing is considered to be over. After prewashing, use 0.5mol / L sodium hydroxide aqueous solution for elution, the flow rate is 0.5BV / h until the pH of the effluent reaches 11.5, and top wash with water until the titer is less than 100u / ml. The analytical solution is decolorized with 711 resin, and the decolorized solution is concentrated and desalted with a nanofiltration membrane with a molecular weight of 200. Add sulfuric acid to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com