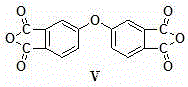

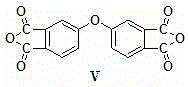

3, 3', 4, 4'-oxydiphthalic dianhydride and 9-oxo(oxa)fluorene dianhydride composition, preparation method and application thereof

A technology of biphenyl ether dianhydride and fluorene dianhydride, which is applied in the field of organic synthesis, can solve problems such as tensile resistance, heat resistance, and insufficient mechanical strength, and achieve the effects of small waste discharge, large application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 1000 g of N,N-dimethylformamide containing 2% water, 250 g of N-methyl-4-nitrophthalimide, 8 g of sodium nitrite and 12 g of sodium nitrate into a 2L autoclave, Raise the temperature to above 165°C and keep it warm for the reaction. The reaction pressure is maintained at 0.05-0.1MPa. After 16 hours of reaction, the temperature is lowered to 60-70°C. The material is transferred to the distillation bottle, and the solvent is recovered. 400 g of water was added to the liquid, crystallized, and filtered to obtain light yellow intermediate compound bis(N-methylphthalimide) ether represented by formula I and compound represented by formula II.

[0033] Put the above-mentioned intermediate, 100g of sodium hydroxide, and 400g of water into the reaction flask, stir and heat up to 100°C for reflux reaction for 12 hours, then add 335g of hydrochloric acid with a mass concentration of 30% for crystallization, cool down to 40-90°C, and filter to obtain the formula III The crude ...

Embodiment 2

[0037] Add 48kg of N,N-dimethylformamide, 2kg of water, 15kg of N-methyl-4-nitrophthalimide, 0.2kg of potassium nitrite, and 0.5kg of copper nitrate into a 100L reaction kettle , stir well to make it evenly mixed, then raise the temperature to 170°C and keep it warm for reaction, the reaction pressure is maintained at 0.15-0.25MPa, and the reaction ends in about 12 hours. After recovering about 38 kg of solvent, 25 kg of water was added thereto, crystallized, and filtered to obtain light yellow intermediate compound bis(N-methylphthalimide) ether represented by formula I and compound represented by formula II.

[0038] Put the above intermediate, 6 kg of sodium hydroxide, and 24 kg of water into the reaction kettle, stir and raise the temperature to 100°C for reflux reaction for 14 hours, then add 20kg of 30% hydrochloric acid for crystallization, cool down to 40-90°C, and filter to obtain the formula III The crude product of the compound 4,4'-diphenyl ether tetracarboxylic ac...

Embodiment 3

[0042]Add 49kg of N,N-dimethylformamide, 1kg of water, 15kg of N-methyl-4-nitrophthalimide, 0.2kg of potassium nitrite, and 0.5kg of sodium nitrate into a 100L reaction kettle , stir well to make it evenly mixed, then raise the temperature to 156-160°C and keep it warm for reaction, the reaction pressure is maintained at 0.05-0.15MPa, and the reaction is completed in about 13 hours. After recovering about 38 kg of solvent, 25 kg of water was added thereto, crystallized, and filtered to obtain light yellow intermediate compound bis(N-methylphthalimide) ether represented by formula I and compound represented by formula II.

[0043] Put the above-mentioned intermediate, 8.5kg potassium hydroxide, and 24 kg water into the reactor, stir and heat up to 100°C for reflux reaction for 14 hours, then add 17kg of 50% sulfuric acid for crystallization, cool down to 40-90°C, and filter to obtain the formula III The crude product of the compound 4,4'-diphenyl ether tetracarboxylic acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com