Waterborne environment-friendly elastic colored coating and preparation method thereof

A colorful coating and environmental protection technology, applied in multi-color effect coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased safety hazards, water seepage and humidity in houses, and only focus on appearance effects, etc., to achieve both flexibility and The effect of stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

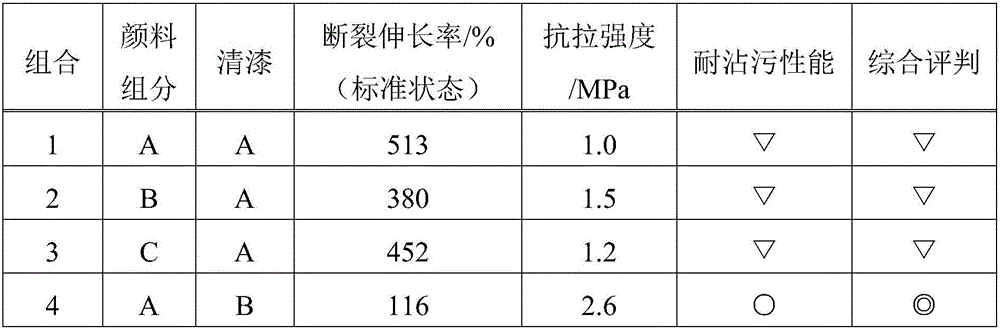

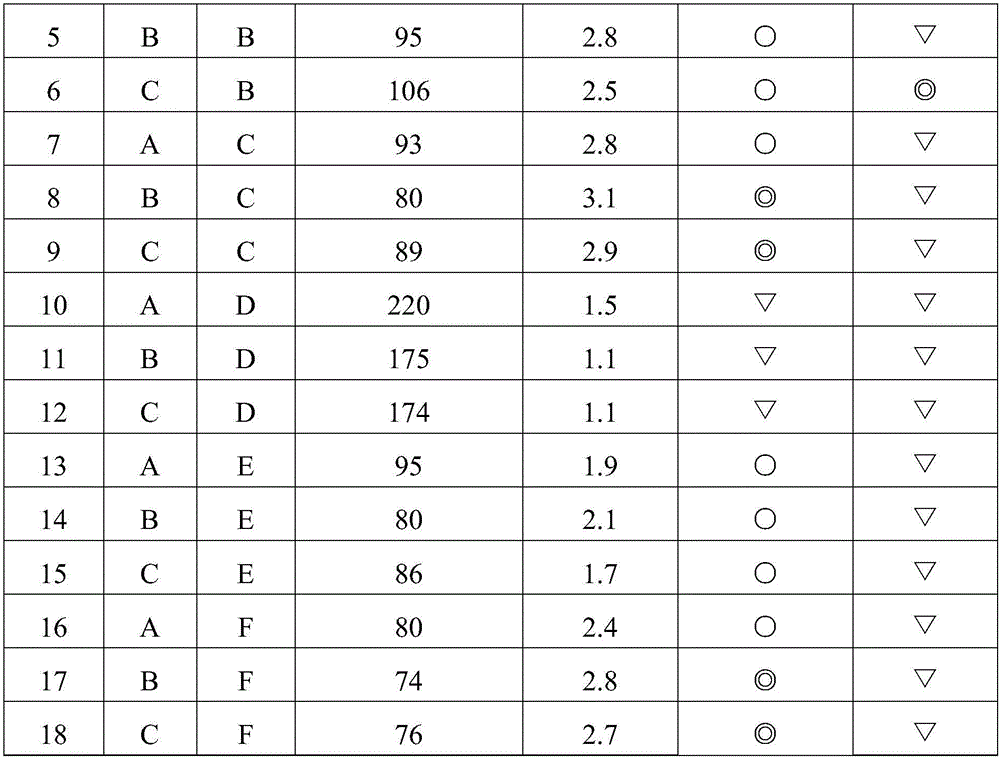

Examples

Embodiment 1

[0066] Pigment component A includes the following components and parts by weight:

[0067] 38.2 parts of water, 0.8 parts of cellulose, 40 parts of emulsion, 0.2 parts of dispersant, 6 parts of pigment and filler, 1 part of anti-aging agent, 0.2 part of defoamer, 1 part of film-forming aid, 1 part of antifreeze, inorganic protective glue 8 parts of solution, 0.3 parts of pH regulator, 0.3 parts of fungicide and 3 parts of thickener A.

[0068] Wherein, the emulsion is a mixture of acrylate polymer emulsion (Tg<0°C) and silicone-modified acrylic resin emulsion (Tg=12°C), in which the acrylate polymer emulsion and silicone-modified acrylic resin emulsion The mass ratio is 7:3.

Embodiment 2

[0070] Pigment component B includes the following components and parts by weight:

[0071] 38.2 parts of water, 0.8 parts of cellulose, 40 parts of emulsion, 0.2 parts of dispersant, 6 parts of pigment and filler, 1 part of anti-aging agent, 0.2 part of defoamer, 1 part of film-forming aid, 1 part of antifreeze, inorganic protective glue 8 parts of solution, 0.3 parts of pH regulator, 0.3 parts of fungicide and 3 parts of thickener A.

[0072] Wherein, the emulsion is a silicone-modified acrylic resin emulsion (Tg=12° C.).

Embodiment 3

[0074] Pigment component C includes the following components and parts by weight:

[0075] 38.2 parts of water, 0.8 parts of cellulose, 40 parts of emulsion, 0.2 parts of dispersant, 6 parts of pigment and filler, 1 part of anti-aging agent, 0.2 part of defoamer, 1 part of film-forming aid, 1 part of antifreeze, inorganic protective glue 8 parts of solution, 0.3 parts of pH regulator, 0.3 parts of fungicide and 3 parts of thickener A.

[0076] Wherein, the emulsion is a mixture of acrylate polymer emulsion (Tg<0°C) and silicone-modified acrylic resin emulsion (Tg=12°C), in which the acrylate polymer emulsion and silicone-modified acrylic resin emulsion The mass ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com