Method for determining COD through rapid digestion

A determination method and rapid technology, applied in the field of analytical chemistry, can solve the problems of heavy metal residual hazards, unsuitable for routine detection, and high price of microwave ovens, so as to facilitate post-processing and environmental protection, reduce labor intensity, and reduce operational risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Water sample digestion

[0024] Take 5.00ml of a standard substance sample of known concentration, add 15.00ml of distilled water; add 10ml of 0.050mol / L potassium dichromate, 20ml of concentrated phosphoric acid, a few glass beads to prevent boiling, connect the heating reflux device, add 0.2g MgSO 4 -MnSO 4 The mixture (weight ratio is 2:1) is heated and digested, and when the sample starts to boil, it is timed to digest for 20 minutes.

[0025] 2) Titration

[0026] After reflux, cool to room temperature, add 75.00ml of distilled water, add 3 drops of ferrous iron indicator, titrate to the end point with 0.020mol / L sodium thiosulfate solution, and record the consumption;

[0027] 3) Blank control test

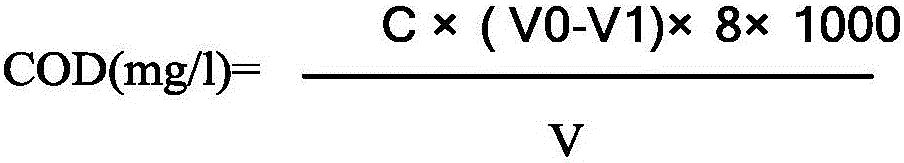

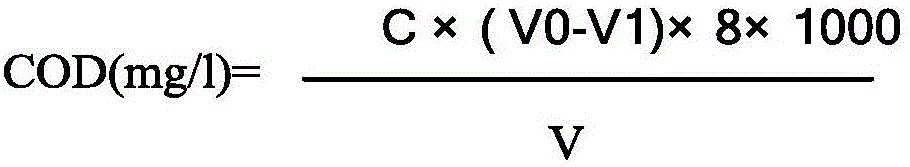

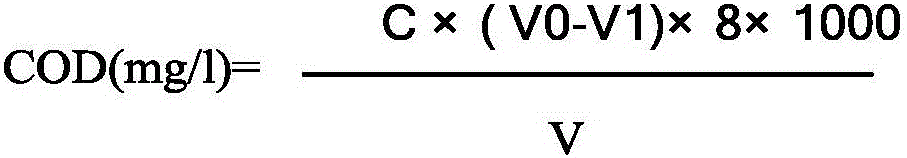

[0028] Use 20ml of distilled water instead of the sample to conduct a blank control test, repeat steps [1) to 2)], record the consumption of sodium thiosulfate solution during blank titration; calculate the COD value according to the formula.

[0029] ...

Embodiment 2

[0032] 1) Water sample digestion

[0033] Take 5.00ml of a standard substance sample of known concentration, add 15.00ml of distilled water; add 13ml of 0.040mol / L potassium dichromate, 25ml of concentrated phosphoric acid, a few glass beads to prevent boiling, connect the heating reflux device, add 0.4g MgSO 4 -MnSO 4 The mixture (weight ratio is 3:1) is heated and digested, and when the sample starts to boil, it is timed to digest for 15 minutes.

[0034] 2) Titration

[0035] After reflux, cool to room temperature, add 100.00ml of distilled water, add 3 drops of ferrous iron indicator, titrate to the end point with 0.015mol / L sodium thiosulfate solution, and record the consumption;

[0036] 3) Blank control test

[0037] Use 20ml of distilled water instead of the sample to enter the blank control test, repeat the operation of steps [1) ~ 2)], record the consumption of sodium thiosulfate solution during blank titration; calculate the COD value according to the formula.

...

Embodiment 3

[0041] 1) Water sample digestion

[0042] Take 5.00ml of a standard substance sample of known concentration, add 15.00ml of distilled water; add 15ml of 0.025mol / L potassium dichromate, 28ml of concentrated phosphoric acid, a few glass beads to prevent boiling, connect the heating and reflux device, and add 0.90g of MgSO 4 -MnSO 4 The mixture (4:1 by weight) was heated and digested, and when the sample began to boil, it was digested for 18 minutes.

[0043] 2) Titration

[0044] After reflux, cool to room temperature, add 90.00ml of distilled water, add 3 drops of ferrous iron indicator, titrate to the end point with 0.025mol / L sodium thiosulfate solution, and record the consumption.

[0045] 3) Blank control test

[0046] Use 20ml of distilled water instead of the sample to enter the blank control test, repeat the operation of steps [1) to 2)], and record the consumption of sodium thiosulfate solution during the blank titration. According to the formula to calculate the COD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com