Solar cell based on nano-onion-carbon composite anode buffer layer

A technology for solar cells and composite anodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of short device life and low photoelectric conversion efficiency, reduce contact barriers, improve air stability and device life, improve Effect of Carrier Transport Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

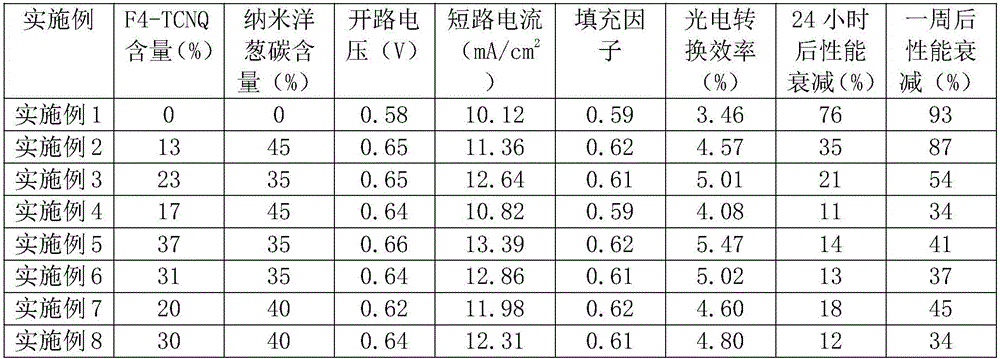

Examples

Embodiment 1

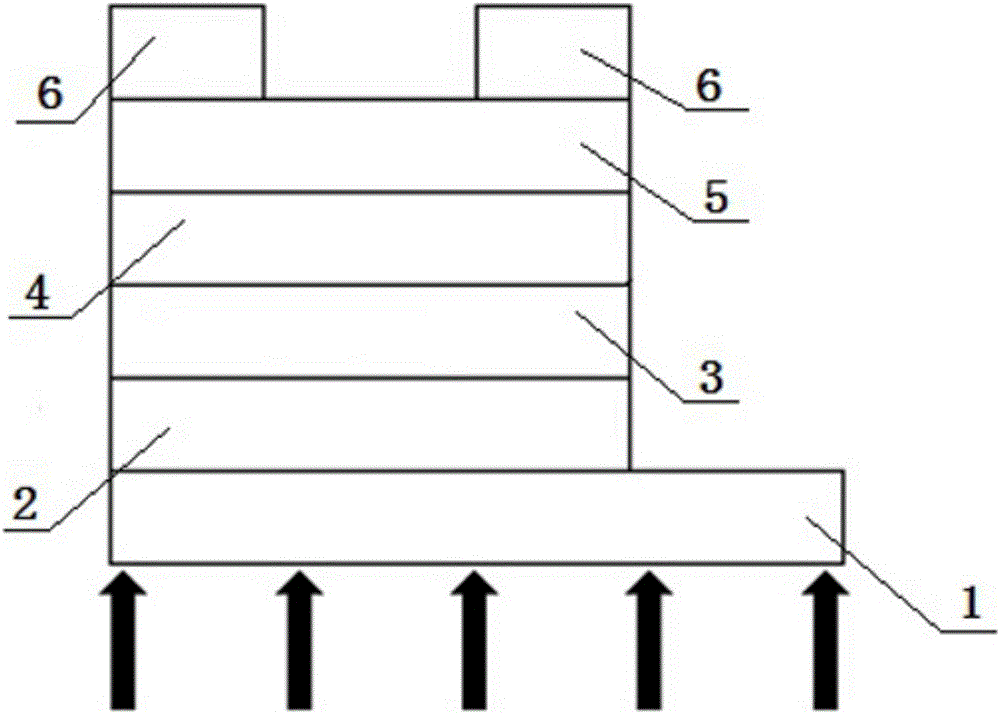

[0027] A solar cell with a shape and structure such as figure 1 As shown, the positive structure is adopted, and the arrangement from bottom to top is as follows: substrate 1, transparent conductive anode ITO 2, anode buffer layer, photoactive layer 4, cathode buffer layer 5, metal cathode 6, the anode buffer layer is conductive Polymer PEDOT:PSS.

[0028] The method for manufacturing a solar cell with a conventional structure provided in this embodiment is as follows: cleaning the substrate composed of a transparent substrate 1 and a transparent conductive anode ITO 2 whose surface roughness is less than 1 nm, and blowing dry with nitrogen after cleaning; The surface of the transparent conductive anode ITO 2 is spin-coated with an anode buffer layer of PEDOT:PSS (3500rpm, 60s, 45nm), and the formed film is baked (150°C, 60min); the anode buffer layer is prepared by spin coating The photoactive layer 4 (1200rpm, 40s) containing PTB7 / PCBM (the mass percentage of PTB7 and PCBM ...

Embodiment 2

[0030] Such as figure 1 As shown, a solar cell based on a nano-onion carbon composite anode buffer layer adopts a positive structure, and is arranged in sequence from bottom to top: substrate 1, transparent conductive anode ITO 2, composite anode buffer layer 3, photoactive layer 4, Cathode buffer layer 5, metal cathode 6, the composite anode buffer layer 3 is composed of conductive polymer PEDOT:PSS, nano-onion carbon and small molecule materials, and the mass percentages of each component in the composite anode buffer layer 3 are respectively: Conductive polymer PEDOT: PSS42%, nano onion carbon 45%, small molecule material 13%, the thickness of the cathode buffer layer 5 is 20-40nm.

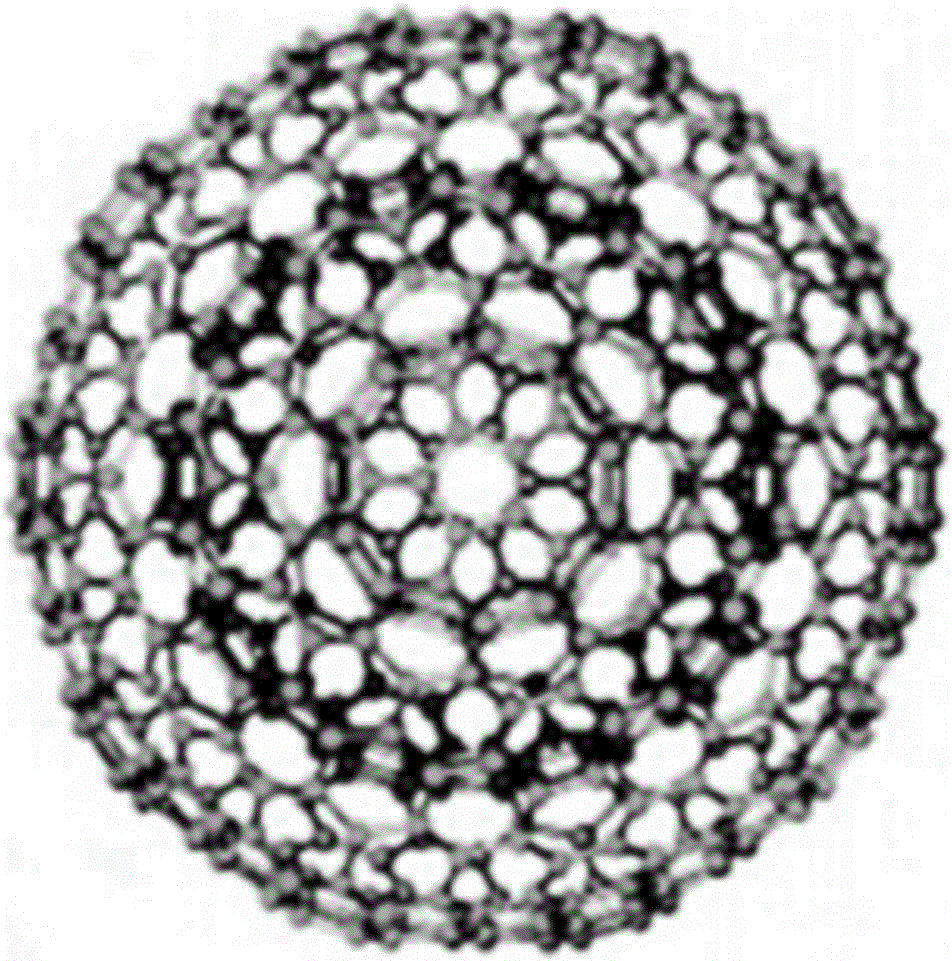

[0031] In this embodiment, the structure of the nano-onion carbon is as follows figure 2 As shown, the nano-onion carbon (Carbon Onions, CNOs) used in this embodiment is the abbreviation of nano-onion-like fullerene. As a new type of carbon material, nano-onion carbon has ultra-high conductiv...

Embodiment 3

[0034] Such as figure 1 As shown, a solar cell based on a nano-onion carbon composite anode buffer layer adopts a positive structure, and is arranged in sequence from bottom to top: substrate 1, transparent conductive anode ITO 2, composite anode buffer layer 3, photoactive layer 4, Cathode buffer layer 5, metal cathode 6, the composite anode buffer layer 3 is composed of conductive polymer PEDOT:PSS, nano-onion carbon and small molecule materials, and the mass percentages of each component in the composite anode buffer layer 3 are respectively: Conductive polymer PEDOT: PSS42%, nano onion carbon 35%, small molecule material 23%, the thickness of the cathode buffer layer 5 is 20-40nm.

[0035] In this embodiment, the structure of the nano-onion carbon is as follows figure 2 As shown, the nano-onion carbon (Carbon Onions, CNOs) used in this embodiment is the abbreviation of nano-onion-like fullerene. As a new type of carbon material, nano-onion carbon has ultra-high conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com