Sludge drying flue gas treatment system and treatment process for municipal sewage treatment plant

A flue gas treatment system and sludge drying technology, which are used in dewatering/drying/concentrating sludge treatment, water/sludge/sewage treatment, gas treatment, etc. There is no substantial reduction in gas and heat pollution, and the odor concentration index cannot meet the standard, etc., to achieve the effects of low operation and maintenance costs, prevention of deposition and blockage, and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

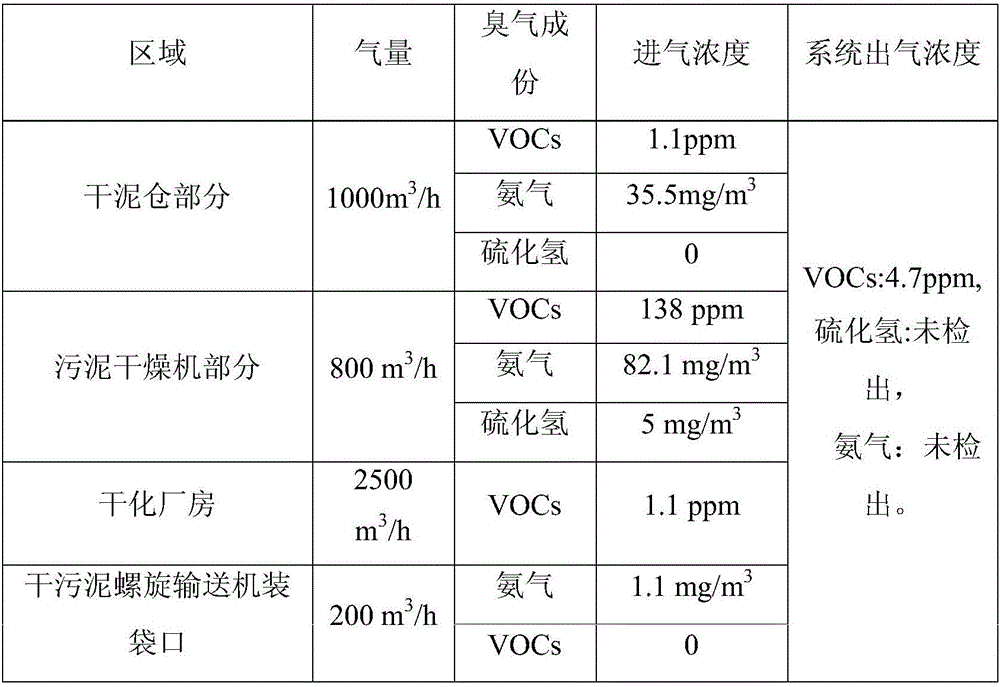

Examples

Embodiment Construction

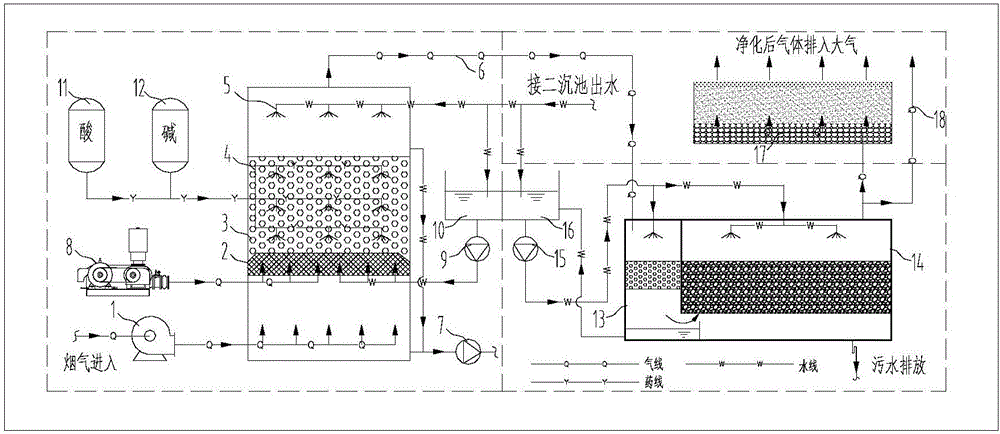

[0034] Such as figure 1As shown, the flue gas treatment system of a kind of municipal sewage plant sludge drying of the present invention includes: including induced draft fan 1, flue gas cooling and backwashing system, biological washing+biological filter system and tail gas advanced treatment system; sludge The dry flue gas outlet is connected in series with the induced draft fan, flue gas cooling and backwashing system, biological scrubbing+biological filter system and exhaust gas advanced treatment system in sequence; the flue gas treatment system also includes flue gas cooling and The auxiliary system of the backwashing system, the auxiliary system of the flue gas cooling and backwashing system includes the backwashing system and the acid-base solution dosing system, which are respectively connected to the flue gas treatment at the flue gas inlet and outlet of the flue gas cooling and backwashing system system.

[0035] A fan 1 is installed at the beginning of the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com