A kind of molasses ethanol fermentation separation coupling method

A technology of ethanol fermentation and molasses, applied in the field of separation and coupling of molasses and ethanol fermentation, can solve problems such as pollution, achieve the effects of reducing product inhibition, reducing membrane fouling, increasing ethanol yield and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

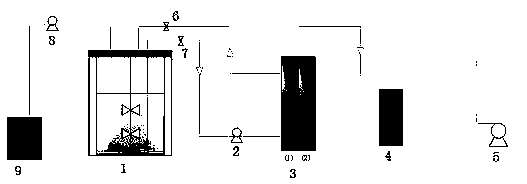

Image

Examples

Embodiment 1

[0029] Example 1: This example illustrates the preparation of alginate-immobilized Saccharomyces cerevisiae

[0030] Saccharomyces cerevisiae Saccharomyces cerevisiae AQ (CCTCC AY 2015008) was mixed with 2% sodium alginate solution, slowly dropped into 4% calcium chloride solution, and the formed white particles were solidified in calcium chloride solution for 4 h, and then washed 3 times with normal saline.

Embodiment 2

[0031] Example 2: This example illustrates the proliferation of alginate-immobilized Saccharomyces cerevisiae

[0032] The prepared immobilized cells were cultured in a 1 L fermenter for about 20-24 h at a temperature of 30 °C and a pH of 5.5.

[0033] Proliferation medium components were 1% yeast extract, 2% peptone, and 2% in situ pretreated molasses.

Embodiment 3

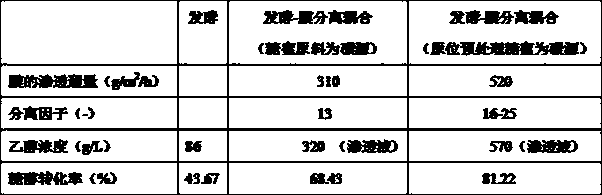

[0034] Embodiment 3: This embodiment illustrates the coupling of fermentation and separation of alginate immobilized S. cerevisiae

[0035] Proliferated immobilized cells were inoculated in the fermentation medium according to 50% of the volume of the fermenter at a temperature of 30 °C.

[0036] pH 5.5. The components of the fermentation medium were 18% in-situ pretreated molasses, 0.2% potassium dihydrogen phosphate, 0.3% magnesium sulfate, 1% ammonium sulfate, and 1% yeast extract.

[0037] When the ethanol concentration in the fermenter reaches 6% (v / v), the membrane separation is started, and the permeate is collected in the cold trap.

[0038] The retentate is returned to the fermenter to continue as culture medium. When the total sugar concentration in the fermenter is lower than 50 g / L, feed the fermenter, and the feed medium is the fermentation medium. After 300 hours of continuous operation, the permeation flux of the membrane is 400 g / m 2 / h, the separation facto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com