Surface protective agent composition, electrical connection structure using the composition, and method for manufacturing the electrical connection structure

一种表面保护剂、电连接结构的技术,应用在永久变形起作用的连接、导电连接、润滑组合物等方向,能够解决难油膜、分子量降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

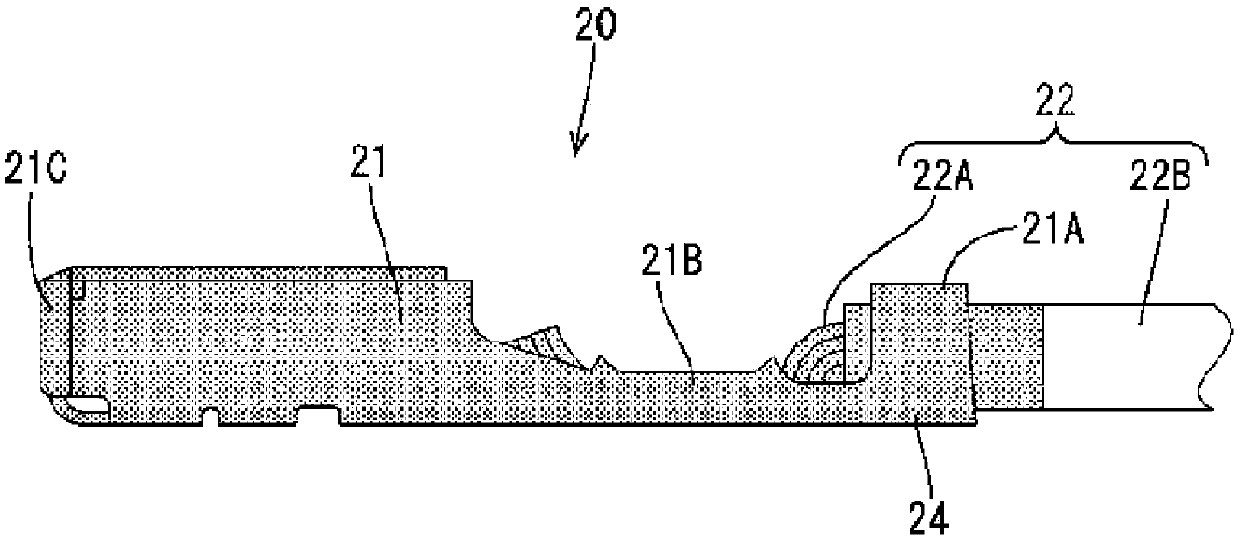

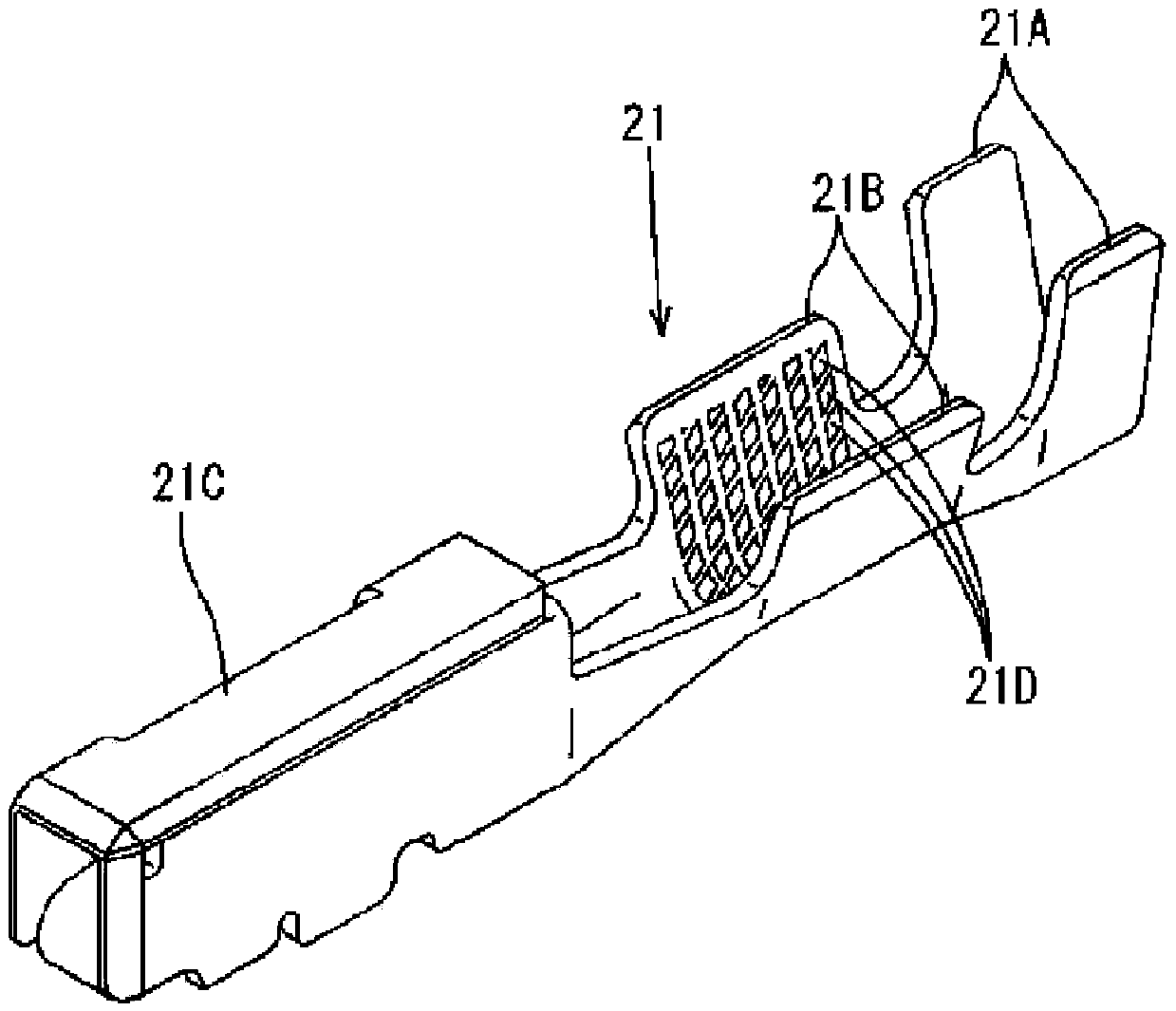

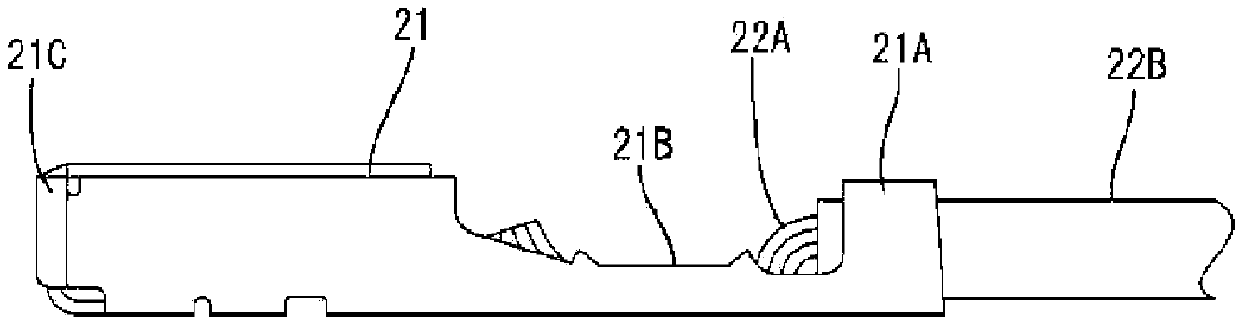

[0170] refer to Figure 1~3 The electrical connection structure 20 according to Embodiment 1 of the present invention will be described. This embodiment is an electrical connection structure 20 having a terminal 21 (an example of a first metal member) containing copper or a copper alloy and a core wire 22A (an example of a second metal member) containing a metal with a stronger ionization tendency than copper. 22 of the wires.

[0171] wire 22

[0172] The electric wire 22 has a core wire 22A wrapped with an insulating coating 22B formed of a synthetic resin. The metal constituting the core wire 22A may be a metal having a stronger ionization tendency than copper, and examples thereof include magnesium, aluminum, manganese, zinc, chromium, iron, cadmium, cobalt, nickel, tin, lead, and alloys thereof. In this embodiment, the core wire 22A contains aluminum or an aluminum alloy.

[0173] The core wire 22A in this embodiment is a twisted wire having a plurality of thin metal ...

Embodiment approach 2

[0186] refer to Figure 4 The electrical connection structure 30 according to Embodiment 2 of the present invention will be described. This embodiment is a copper electric wire 32 having a copper core wire 32A (an example of a second metal member) containing copper or a copper alloy, and an aluminum core wire 33A (another example of a second metal member) containing aluminum or an aluminum alloy. ) aluminum electric wires 33 are connected to each other through connection terminals 31. The outer circumference of the copper core wire 32A is coated with an insulating coating 32B formed of synthetic resin, and the outer circumference of the aluminum core wire 33A is coated with an insulating coating 33B formed of synthetic resin. Descriptions that overlap with Embodiment 1 will not be repeated here.

[0187] In this embodiment, the copper core wire 32A and the aluminum core wire 33A are electrically connected through the connection terminal 31 . The connection terminal 31 has a...

Embodiment

[0192] The content of the present invention will be described in more detail below in conjunction with examples and comparative examples, but the present invention is not limited by these examples. The following examples are based on Embodiment 1 (figure (b)).

[0193] surface protectant composition

[0194] According to the formula shown in Table 1, the surface protective agent composition of the present invention (Examples 1-4) and the composition for comparison (Comparative Examples 1-4) were prepared.

[0195] [Table 1]

[0196]

[0197] (a-1) Mineral base oil, kinematic viscosity (100°C): 4.0mm 2 / s, %CP: 66.9%

[0198] (a-2) Mineral base oil, kinematic viscosity (100°C): 11.1mm 2 / s, %CP: 66.1%

[0199] (a-3) Mineral base oil, kinematic viscosity (100°C): 32.0mm 2 / s, %CP: 66.9%

[0200] (b-1) Zn salt of (2-ethylhexyl) phosphate, P content: 7.2% by mass

[0201] (b-2) Zn salt of isostearyl phosphate, P content: 6.0% by mass

[0202] (b-3) Ca salt of isosteary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com