Hydrophilic modified polymer membrane as well as preparation method and application thereof

A hydrophilic modification and polymer technology, which is applied in the field of oil-water separation filter membrane, amphiphilic ion polyelectrolyte modified hydrophilic and pollution-resistant polymer porous membrane, which can solve the problems of unsuitable for industrial application, membrane fouling, high cost, etc. problem, to achieve the effect of oil-water separation flux and anti-pollution performance improvement, simple and controllable preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

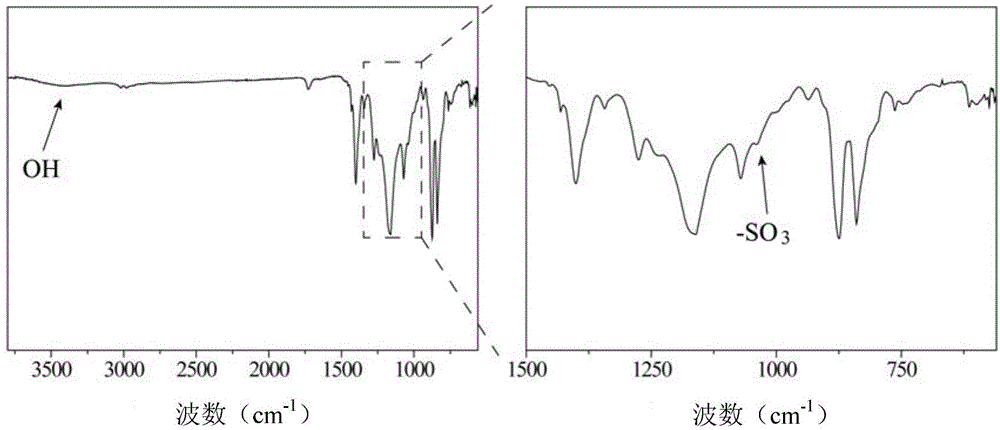

[0032] In a typical implementation case, the preparation method of the polymer hydrophilic modified membrane may include the following steps:

[0033] Ⅰ. The cross-linked hydrophilic copolymer that can be amphiphilic and ionized is prepared by free radical polymerization. The molar ratio of the comonomer dimethylaminoethyl methacrylate to other comonomers is 6:4 to 8:2. The volume ratio of the reaction solvent water and ethanol is 7:3 to 4:6, and the polymerization temperature is 25°C to 60°C;

[0034] II. The post-crosslinked hydrophilic copolymer prepared in step I, which can be amphiphilic and ionized, and polyvinylidene fluoride (including but not limited to polyvinylidene fluoride) according to the mass ratio of 1:4 to 1:1 Proportionally dissolved in a solvent to prepare a casting solution;

[0035] Ⅲ. The casting solution prepared in step Ⅱ is prepared through liquid-induced phase inversion to prepare a porous separation membrane. In the hydrogel bath used for the liqui...

Embodiment 1

[0041] Measure 5.6ml monomer dimethylaminoethyl methacrylate and 2.4ml hydroxyethyl methacrylate, weigh 0.16g sodium sulfate (Na 2 S 2 o 8 ) and 0.16g sodium bisulfite (NaHSO 3 ), dissolved in 40ml of mixed solvent of water and ethanol, the volume of water and ethanol is 1:1, under the condition of 60 ℃, polymerization reaction for 3h, after purification, the cross-linked hydrophilic copolymer that can be amphiphilic and ionized is obtained ;

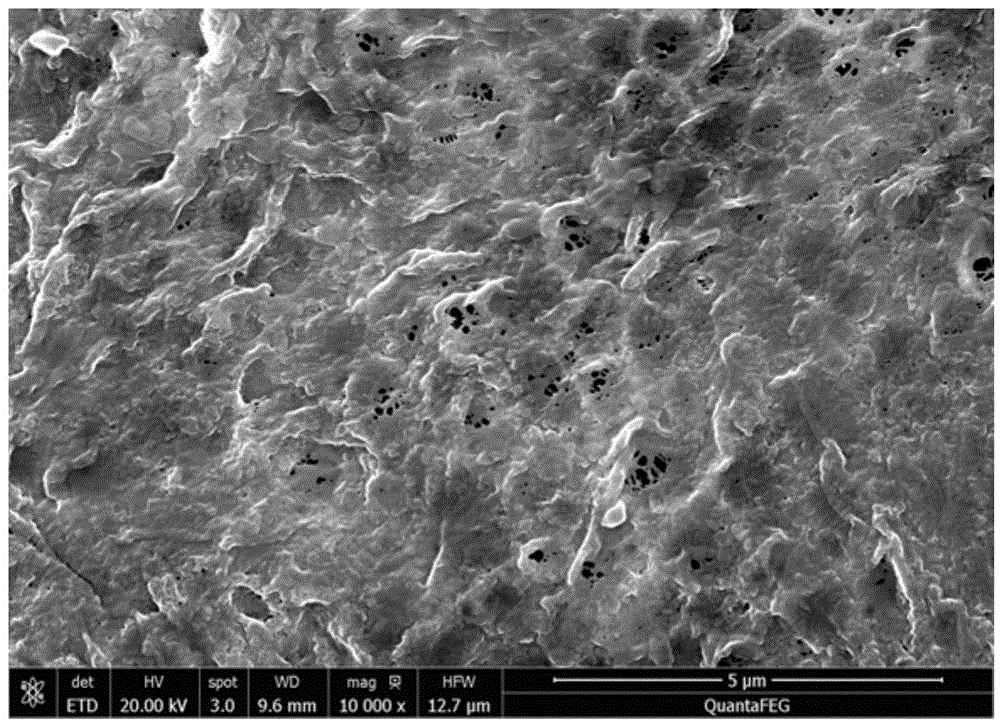

[0042]Weigh 1g of amphiphilic ionizable post-crosslinked hydrophilic copolymer and 1g of polyvinylidene fluoride, and dissolve them in 10ml of N,N-dimethylformamide containing 4% water by volume at 70°C , be prepared into 20wt% casting liquid, after standing for 12h for defoaming, then scrape the casting liquid evenly onto the surface of clean glass with a film scraper, the edge of the scraper is 200 μm away from the glass surface, and then Immediately immerse in the gel bath for 60min phase inversion, then take it out and put it in...

Embodiment 2

[0044] Measure 6.5ml monomer dimethylaminoethyl methacrylate and 1.8ml hydroxyethyl methacrylate, weigh sodium sulfate 0.16g (Na 2 S 2 o 8 ) and 0.16g sodium bisulfite (NaHSO 3 ), dissolved in 40ml of mixed solvent of water and ethanol, the volume of water and ethanol is 1:1, under the condition of 60 ℃, polymerization reaction for 3h, after purification, the cross-linked hydrophilic copolymer that can be amphiphilic and ionized is obtained ;

[0045] Weigh 1g of amphiphilic ionizable post-crosslinked hydrophilic copolymer and 1g of polyvinylidene fluoride, and dissolve them in 10ml of N,N-dimethylformamide containing 4% water by volume at 70°C , be prepared into 20wt% casting liquid, after standing for 12h for defoaming, then scrape the casting liquid evenly onto the surface of clean glass with a film scraper, the edge of the scraper is 200 μm away from the glass surface, and then Immediately immerse in the gel bath for 60min phase inversion, then take it out and put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com