Preparation method for electro-catalysis hydrogen evolution copper nanometer particles/carbon nanofiber hybrid materials

A technology of carbon nanofibers and hybrid materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of difficulty in preparing dispersion, unstable copper nanoparticles, and easy oxidation Copper oxide and other problems, to achieve the effect of abundant raw materials, cheap raw materials, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

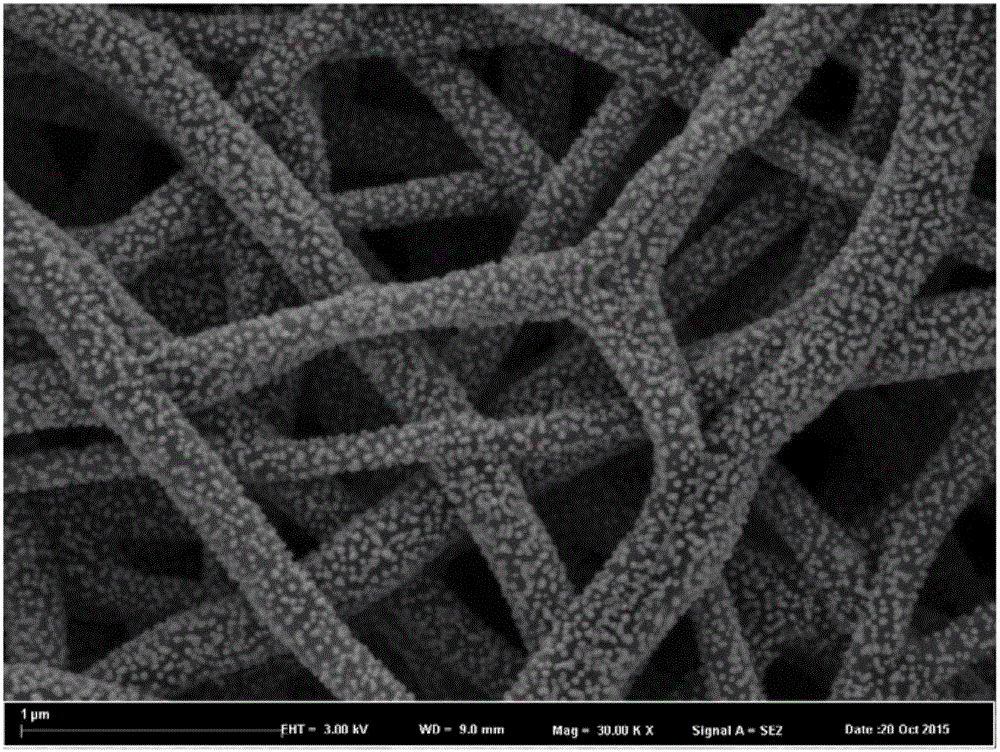

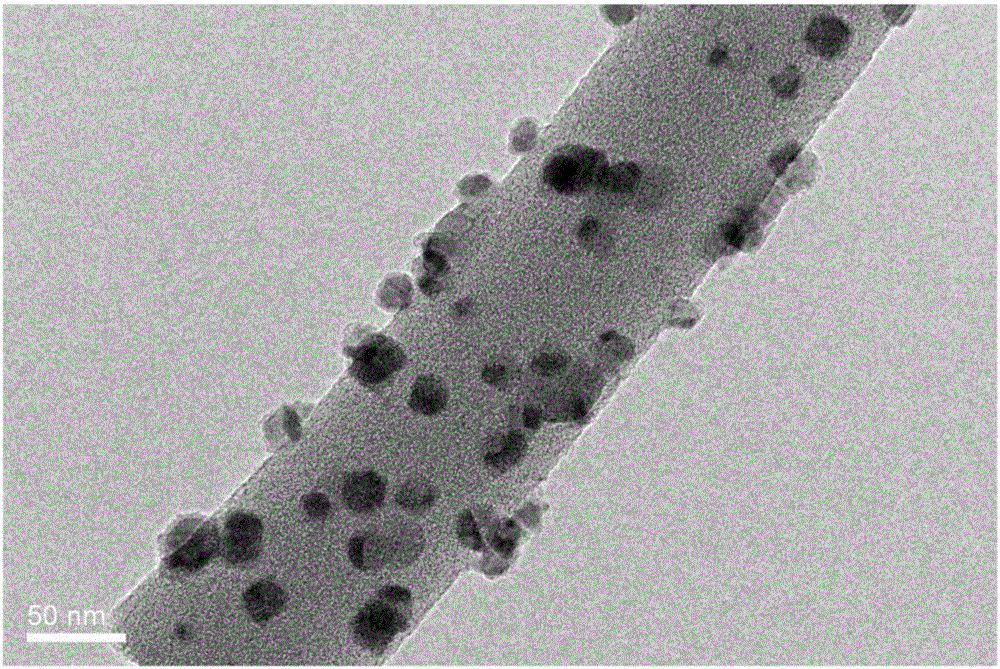

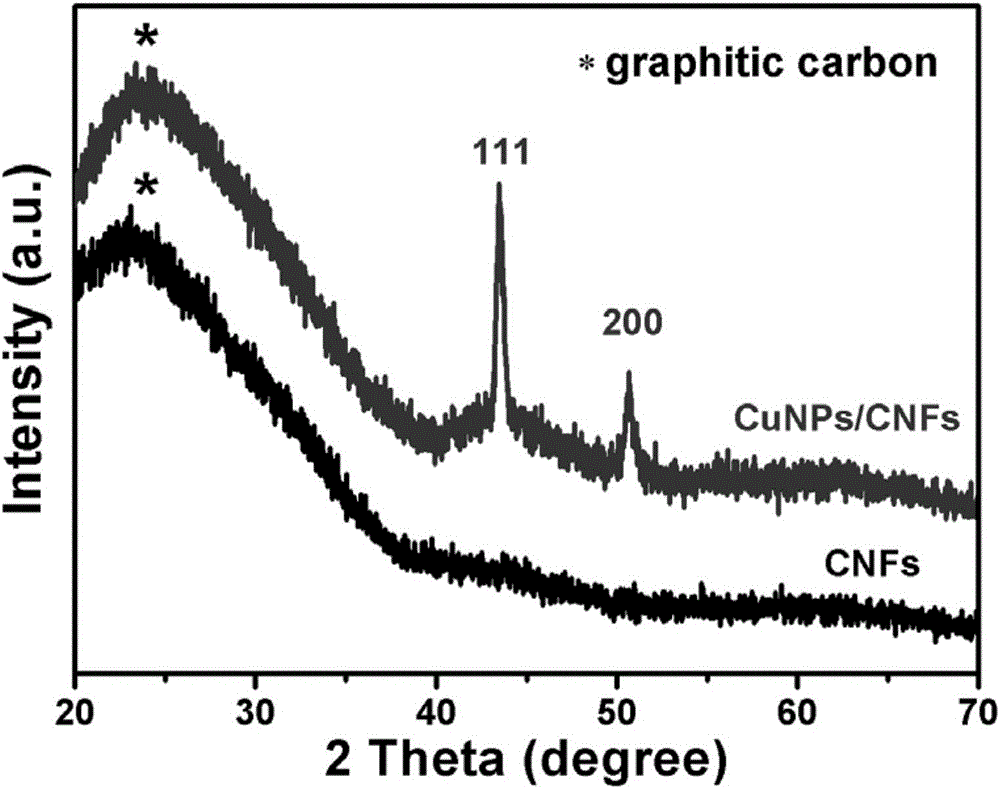

[0031] Dissolve 1.5 grams of polyvinyl alcohol (PVA) powder in deionized water to form an aqueous solution with a mass concentration of 12%, then slowly add 0.075 grams of copper chloride to the above solution, and keep stirring until the solution is evenly mixed. A precursor solution containing copper salt and polyvinyl alcohol polymer is obtained. Move the prepared precursor solution to a 10mL syringe, and fix the syringe on the micropump injector. The needle of the syringe is connected to the positive pole of the high-voltage DC power supply, and the collection plate covered with aluminum foil is connected to the negative pole of the high-voltage DC power supply. The distance between the collection plate and the needle is 12 cm, the injection speed of the micropump is 0.3 mL / h, the positive voltage is set to 15 kV, and the negative voltage is set to 1.0 kV. The composite nanofibers of copper salt and polyvinyl alcohol can be collected on the collecting plate; the composite ...

Embodiment 2

[0033] Take 2.0 grams of polyacrylonitrile (PAN) powder and dissolve it in N,N-dimethylformamide solution to form a solution with a mass concentration of 10%, then slowly add 0.075 grams of copper nitrate to the above solution, and keep stirring Until the solution is uniformly mixed, a precursor solution containing copper salt and polyacrylonitrile polymer can be obtained. Move the prepared precursor solution to a 10mL syringe, and fix the syringe on the micropump injector. The needle of the syringe is connected to the positive pole of the high-voltage DC power supply, and the collection plate covered with aluminum foil is connected to the negative pole of the high-voltage DC power supply. The distance between the collection plate and the needle is 15 cm, the injection speed of the micropump is 0.6 mL / h, the positive voltage is set to 12 kV, and the negative voltage is set to 2.0 kV. The composite nanofibers of copper salt and polyacrylonitrile can be collected on the collecti...

Embodiment 3

[0035]Take 1.5 grams of polyvinylpyrrolidone (PVP) and dissolve the powder in N,N-dimethylformamide solution to make a solution with a mass concentration of 10%, then slowly add 0.075 grams of copper sulfate to the above solution, and keep stirring Until the solution is uniformly mixed, a precursor solution containing copper salt and polyvinylpyrrolidone polymer can be obtained. Move the prepared precursor solution to a 10mL syringe, and fix the syringe on the micropump injector. The needle of the syringe is connected to the positive pole of the high-voltage DC power supply, and the collection plate covered with aluminum foil is connected to the negative pole of the high-voltage DC power supply. The distance between the collection plate and the needle is 10 cm, the injection speed of the micropump is 0.5 mL / h, the positive voltage is set to 17 kV, and the negative voltage is set to 1.5 kV. The composite nanofibers of copper salt and polyvinylpyrrolidone can be collected on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com