Converted production well pretreating agent suitable for middle-low-permeability reservoir and preparation method

A pretreatment agent and oil seepage technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low biodegradation rate, long construction time, impossibility of implementation, etc., achieve high degree of biodegradation, avoid secondary Secondary pollution and reduced construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

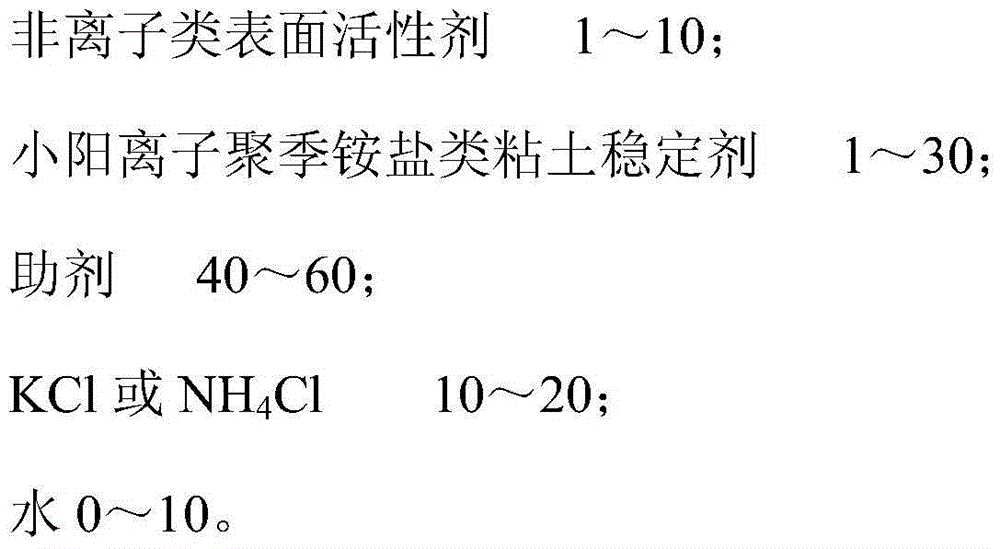

Method used

Image

Examples

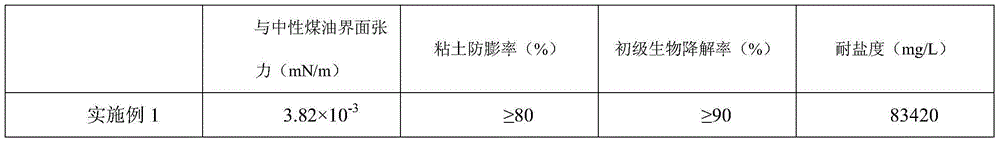

Embodiment 1

[0026] Take 10 kg of KCl or NH 4 Cl, first add 30 kg of Cl with the molecular formula (C 7 h 18 2N2Br) n , n=2~5 small cationic polyquaternium clay stabilizer, then add 1 kg of APG0810 nonionic surfactant, then add 60 kg of ethylene glycol monobutyl ether, stir evenly to obtain the product.

[0027] The method of use is:

[0028] (1) The clear water well fluid used to prepare the treatment agent solution is finely filtered through the fiber composite membrane to ensure that the solid phase particle diameter and solid phase content of the well fluid meet the standards of the petroleum and natural gas industry of the People's Republic of China "SY / T 5329-2012 Injection water quality indicators and analysis methods for clastic rock reservoirs "Recommended main control indicators of water quality in 4.2";

[0029] (2) Requirements for the temperature of the entering well fluid: for crude oil with a freezing point above 0°C, the temperature of the entering well fluid should be ...

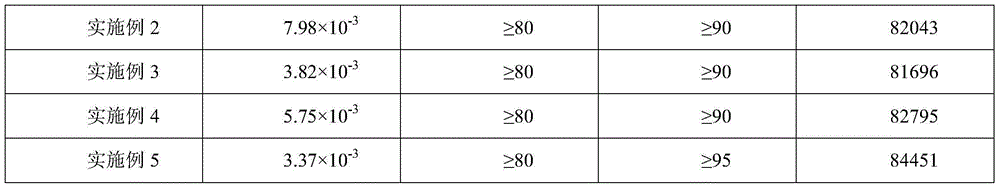

Embodiment 2

[0033] Take 20 kg of KCl or NH 4 Add Cl to 10 kg of water, mix well under the condition of temperature of 0°C and stirring speed of 10 r / min, then continue stirring, first add 1 kg of water with the molecular formula (C 7 h 18 2N2Br) n , n=2~5 small cationic polyquaternium clay stabilizer, then add 10 kg of APG0810 nonionic surfactant, finally add 40 kg of ethylene glycol monobutyl ether, stir evenly to obtain the product.

[0034] The method of use is:

[0035] (1) The clear water well fluid used to prepare the treatment agent solution is finely filtered through the fiber composite membrane to ensure that the solid phase particle diameter and solid phase content of the well fluid meet the standards of the petroleum and natural gas industry of the People's Republic of China "SY / T 5329-2012 Injection water quality indicators and analysis methods for clastic rock reservoirs "Recommended main control indicators of water quality in 4.2";

[0036] (2) Requirements for the tempe...

Embodiment 3

[0040] First, 15 kg of KCl or NH 4 Add Cl into 5 kg of water, mix well at a temperature of 15°C and a stirring speed of 7 r / min, then continue to stir, first add 15 kg of water with the molecular formula (C 7 h 18 2N2Br) n , n=2~5 small cationic polyquaternium clay stabilizer, then add 5 kg of APG0810 nonionic surfactant, finally add 50 kg of ethylene glycol monobutyl ether, stir evenly to obtain the product.

[0041] The method of use is:

[0042] (1) The well-entry fluid used to prepare the treatment agent solution comes from oilfield sewage, and the oilfield sewage undergoes solid phase sedimentation, multi-layer filter material filtration and multi-stage filtration of fiber composite membrane after degreasing. Ensure that the solid particle diameter and solid content of the well fluid reach the main control indicators recommended in 4.2 of the Petroleum and Natural Gas Industry Standard of the People's Republic of China "SY / T 5329-2012 Injection Water Quality Indicators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| salt tolerance | aaaaa | aaaaa |

| salt tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com