A kind of fermentation production process of α-ketobutyric acid

A technology of ketobutyric acid and production method, which is applied in the directions of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of high substrate production cost, decreased bacterial biomass and high product toxicity, and achieves improved The effect of bacterial biomass, increasing fermentation level, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

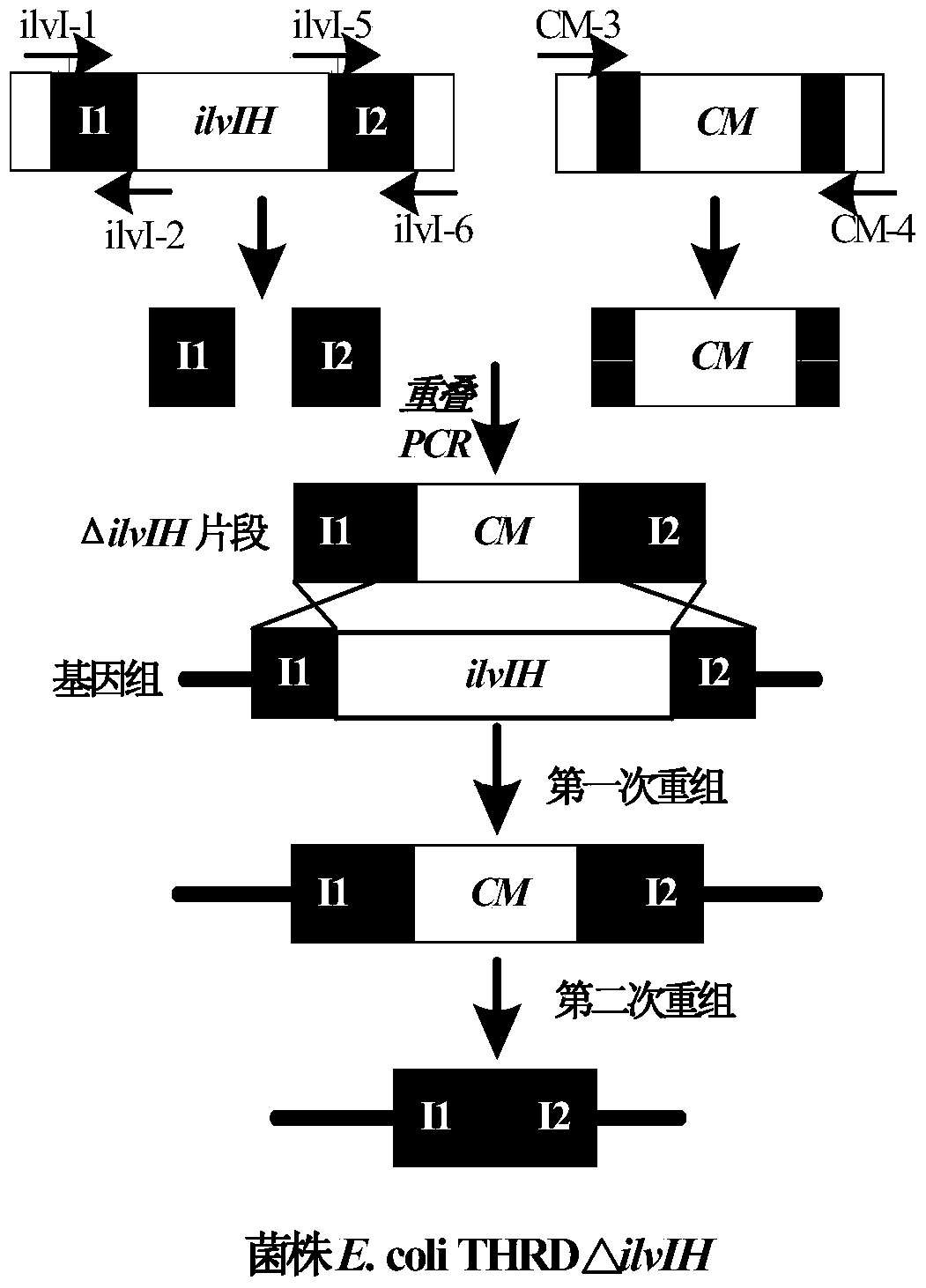

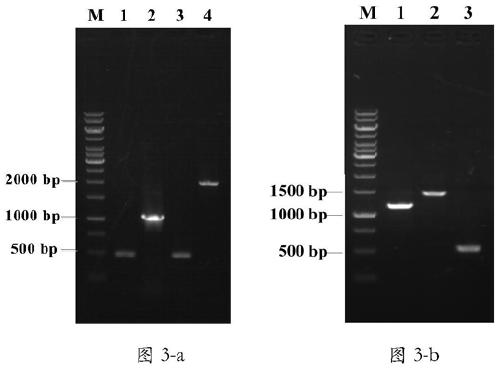

[0053] Example 1: Construction of a genetically engineered strain E.coli THRD△ilvIH+PBV220-ilvA producing ɑ-ketobutyric acid

[0054] 1. Knockout of gene ilvI encoding acetohydroxyacid synthase III large subunit

[0055] (1) Design upstream and downstream homology arm amplification primers ilvI-1, ilvI-2, ilvI-5 and ilvI-6 according to the 5' and 3' end 500bp sequences of the ilvI gene in E.col iMG1655 in the NCBI database, and use E The genome DNA of the coliTHRD strain (Accession No. CGMCC No. 11074) is used as a template to amplify homology arm fragments. The PCR amplification conditions were 1 cycle at 95°C for 5 min, 25 cycles at 94°C for 30 s, 56°C for 30 s, 1 min at 72°C, and 1 cycle at 72°C for 10 min, and the reaction system was 50 μL.

[0056] (2) Design amplification primers CM-3 and CM-4 according to the chloramphenicol resistance gene sequence in the plasmid pKD3, and amplify the chloramphenicol resistance gene fragment using the plasmid pKD3 as a template, and t...

Embodiment 2

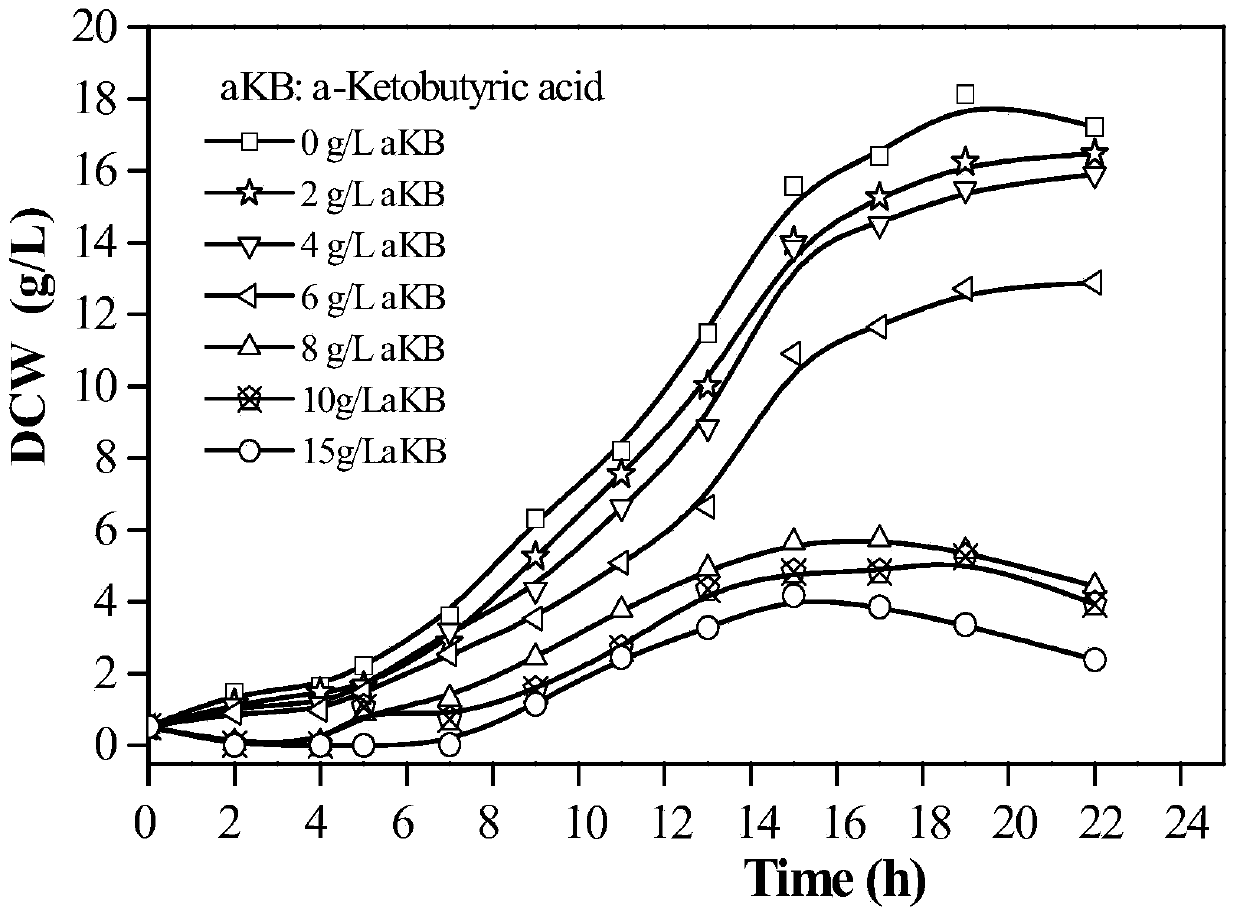

[0070] Embodiment 2: Shake flask fermentation of genetically engineered bacteria producing α-ketobutyric acid

[0071] Strain: E.coli THRD△ilvIH+PBV220-ilvA Resistance: Amp R

[0072] Seed culture: strains passed through Amp R After two generations of slant activation, scrape 1 ring of wet bacteria with an inoculation needle under sterile conditions and inoculate into 30mL containing 100μg / mL Amp R in the seed medium. Cultivate at 37°C and 200rpm for 8h, during which the pH is adjusted to ≈7.0 with ammonia water according to the color change of the indicator.

[0073] Fermentation conditions: After culturing the seed liquid for 8 hours, the seed liquid OD 600=8, use a sterilized 5mL pipette to draw 3mL seed solution under aseptic conditions and connect to 27mL containing 100μg / mL Amp R In the fermentation medium, the inoculum size was 10%. 35°C, 200rpm to start fermentation culture, when the fermentation broth OD 600 =15, directly increase the temperature to 42°C to in...

Embodiment 3

[0077] Embodiment 3: 7.5L fermenter fermentation of genetically engineered bacteria producing α-ketobutyric acid

[0078] Strain: E.coli THRD△ilvIH+PBV220-ilvA Resistance: Amp R

[0079] Seed culture: strains passed through Amp R After two generations of slant activation, under aseptic conditions, all the wet thallines on 4 slants were inoculated into a 5L seed tank with 2L seed culture medium with an inoculation needle, and 25% (W / V) ammonia water was added to regulate the seeds. The pH of the solution is 7.0, the dissolved oxygen is maintained at about 30-50% by increasing the rotating speed and the ventilation rate, and the culture is carried out at a constant temperature of 37°C.

[0080] Fermentation conditions: waiting for seed liquid OD 600 When=15, 500mL seed liquid is transferred in the 7.5L fermentor that contains aseptic fermentation medium, and total liquid volume is 4L, and inoculum size is 12%. Cultivate at 35°C, add 25% (W / V) ammonia water during the period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com