Processing method of nutritional rice flour

A nutritional rice flour and processing method technology, applied in the field of food processing, can solve problems such as poor mastery, influence on patient prognosis, and unoptimistic implementation of dietary doctor's orders, and achieve the effects of improving human immunity, improving kidney function, and facilitating human body absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

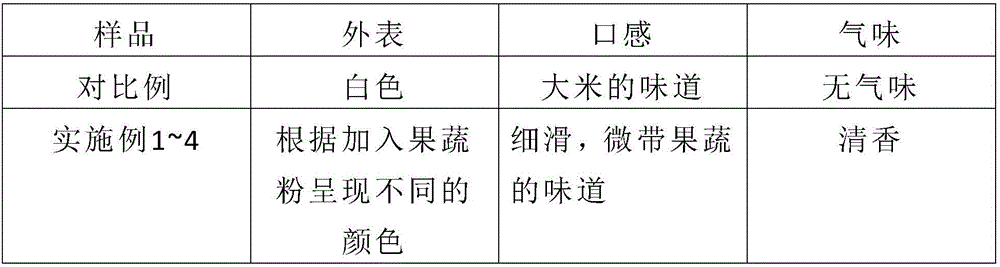

Examples

Embodiment 1

[0021] Embodiment 1: the processing method of nutritious rice flour

[0022] (1) Preparation of low protein-low phosphorus rice flour:

[0023] Using rice as raw material, first wash it with water, grind it into rice milk, then add papain and bromelain compound protease to the rice milk for proteolysis treatment, wherein the weight ratio of papain and bromelain is 1:4, the compound protease The dosage is 0.2% of the mass of rice milk, reaction pH: 9.5, temperature: 20°C, time: 5h, after proteolysis treatment, add Lactobacillus delbrueckii (L.delbrueckii) of the genus Lactobacillus and thermophilic milk chain of the genus Streptococcus Coccus (S.thermophilus) joint fermentation, Lactobacillus delbrueckii (L.delbrueckii) and thermophilic streptococcus (S.thermophilus) (S.thermophilus) two parts by weight ratio 1:10 to make lactic acid starter, the dosage of lactic acid starter is 0.2% of the mass of rice milk, reaction pH: 7.0, temperature: 35° C., time: 3 hours, then centrifug...

Embodiment 2

[0030] Embodiment 2: the processing method of nutritious rice flour

[0031] (1) Preparation of low protein-low phosphorus rice flour:

[0032] Using rice as raw material, wash it with water first, grind it into rice milk, then add bromelain to the rice milk for proteolysis treatment, the dosage of bromelain is 1% of the mass of rice milk, reaction pH: 3.0, temperature: 50°C, time: 1h, after proteolysis treatment, add Lactobacillus delbrueckii (L.delbrueckii) and Streptococcus thermophilic Streptococcus lactis (S.thermophilus) for joint fermentation, Lactobacillus delbrueckii (L.delbrueckii) and thermophilic Streptococcus lactis (S.thermophilus) made a lactic acid starter with a weight ratio of 10:1, the amount of lactic acid starter was 0.2% of the mass of rice milk, reaction pH: 5.0, temperature: 30°C, time: 1h, Then the rice milk after protein hydrolysis is centrifuged, washed with water, and dried to obtain low-protein-low-phosphorus rice flour.

[0033] (2) Preparation ...

Embodiment 3

[0039] The processing method of embodiment 3 nutritious rice noodles

[0040] (1) Preparation of low protein-low phosphorus rice flour:

[0041] Using rice as raw material, wash it with water first, grind it into rice milk, heat it to 96°C, keep it warm for 0.5 minutes, cool it to 30°C, then add neutral protease to the rice milk for proteolysis treatment, the amount of neutral protease is the mass of rice milk 0.5%, reaction pH: 7.0, temperature: 60°C, time: 2.5h, add Pediococcus lactic acid Pediococcus (P.acidilactic), Lactobacillus acidophilus Lactobacillus (L.acido phlus) and Joint fermentation of Leuconostoc enterococci subspecies milk fat, the ratio of the three parts by weight is 10:1:10, the amount of lactic acid starter is 0.2% of the mass of rice milk, the reaction pH: 5.0, temperature: 42°C, time: 1h , and then centrifuging the rice milk after protein hydrolysis, washing with water, and drying to obtain deproteinized and dephosphorized rice flour.

[0042] (2) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com