Tadalafil containing orally-dissolved film agent and preparation method thereof

A technology of tadalafil and oral dissolving film, applied in the directions of pharmaceutical formulations, sexually transmitted diseases, sheet conveying, etc., can solve the problems such as affecting the health of production personnel, high requirements for workshop ventilation and explosion-proof, and increased production costs. Improve the therapeutic effect, novel dosage form, convenient medication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

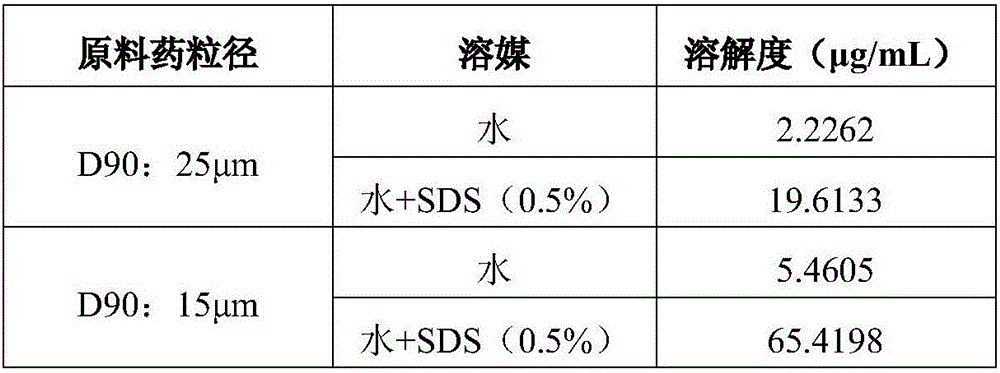

[0052] Embodiment 1: the impact of bulk drug particle size on product quality

[0053]

[0054] Note: *: used in prescription but removed in final product.

[0055] The film prepared from the above components is dark yellow, has good flatness and foldability, plasticity and toughness, and the breaking force is within 12-16N, meeting the requirements of cutting, packaging, transportation and clinical use. The melting time is within 20 to 25 seconds, and there is no significant difference. The actual melting time in the mouth is about 10 to 15 seconds. There is no sticky feeling and the taste is good.

[0056] The above results show that: the particle size of tadalafil API D90 in the range of 10 to 25 μm has no significant impact on the physical properties and melting time of the product.

Embodiment 2

[0057] Embodiment 2: the impact of bulk drug, film-forming agent, plasticizer consumption on product quality

[0058]

[0059] Note: *: used in prescription but removed in final product.

[0060] The film prepared from the above-mentioned components has good flatness, foldability, plasticity and toughness, and the breaking force is within 11-19N, meeting the requirements of cutting, packaging, transportation and clinical use. The melting time is within 20 to 30 seconds, without significant difference, and the melting time in the mouth is about 10 to 20 seconds, with no sticky feeling and good taste.

[0061] The above results show that when the proportion of the raw material is in the range of 20-50%, the proportion of the film-forming agent is in the range of 30-60%, and the proportion of the plasticizer is in the range of 10-20%, the product has good characteristics in terms of plasticity, toughness and melting time limit.

Embodiment 3

[0062] The influence of embodiment 3 solubilizing agent and transdermal absorption accelerator on product quality

[0063]

[0064] Note: *: used in prescription but removed in final product.

[0065] The film prepared from the above components has good flatness, foldability, plasticity and toughness, and the breaking force is within 13-17N, meeting the requirements of cutting, packaging, transportation and clinical use. The melting time is within 20 to 30 seconds, without significant difference, and the melting time in the mouth is about 10 to 20 seconds, with no sticky feeling and good taste.

[0066] The above results show that when the proportion of the solubilizer is 2-10%, and the proportion of the transdermal absorption accelerator is within the range of 0.5-5%, the physical properties and melting time of the product meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com