Degradable macromolecule network and calcium phosphate bone cement composite bone repair material and preparation method and application thereof

A technology of calcium phosphate bone cement and polymer network, which is applied in additive processing, medical science, prosthesis, etc., to achieve good mechanical properties and biological properties, increase specific surface area, and good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

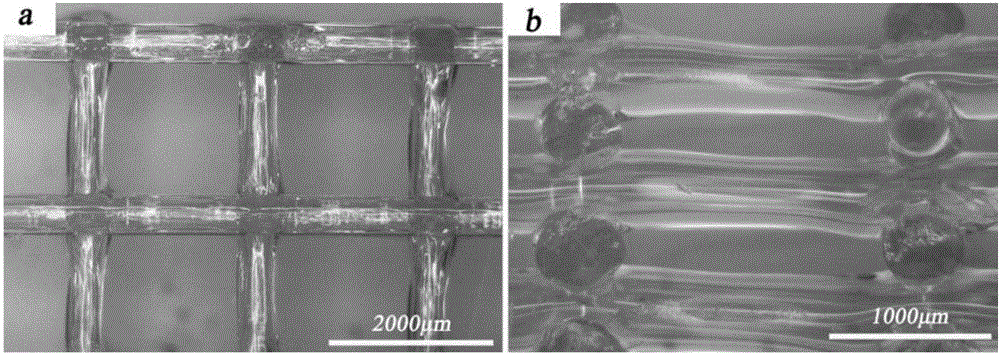

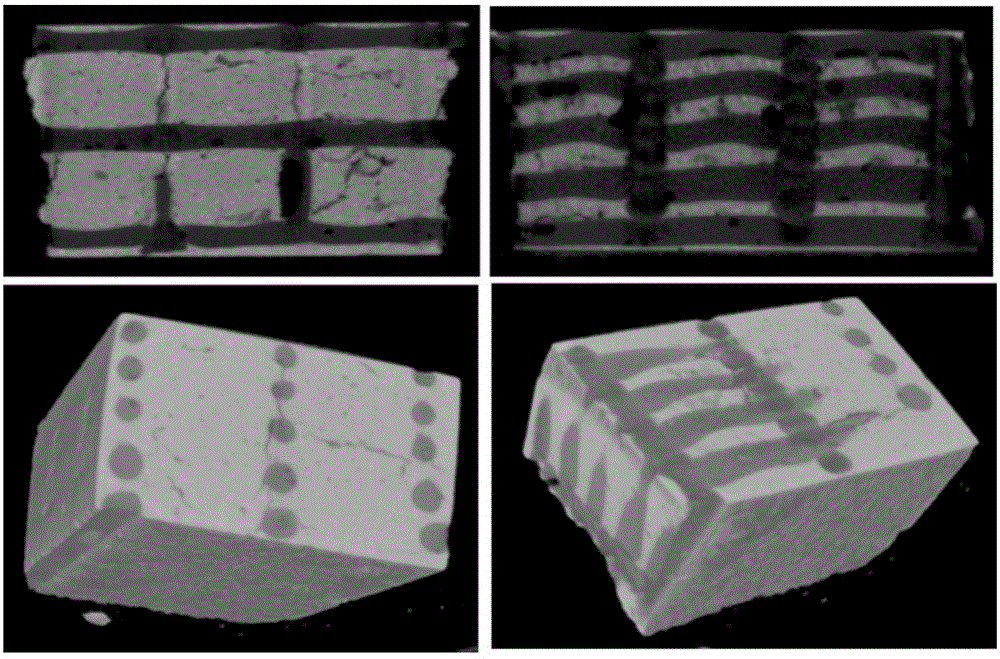

[0052] The "partially crystalline calcium phosphate-anhydrous calcium hydrogen phosphate" system bone cement was selected and prepared by 3D printing with a molecular weight of 30kDa and a monomer ratio of PLA:PGA=50:50. PLGA with terminal-COOH could form a three-dimensional connected porous structure network in situ. Equipped with an appropriate device, the calcium phosphate bone cement slurry is poured into the PLGA porous network to prepare a degradable polymer network / calcium phosphate bone cement composite bone repair material. The implementation steps include:

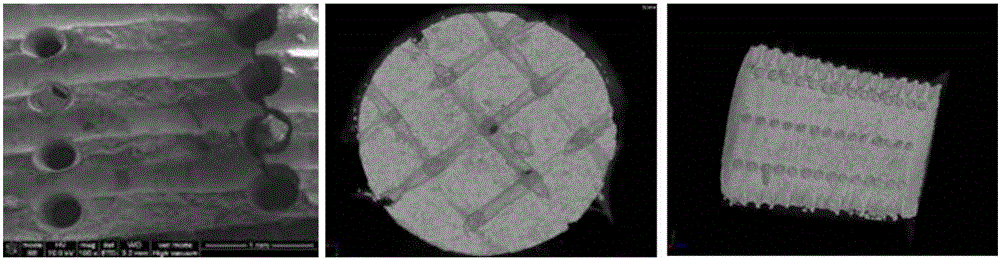

[0053] (1) Use Magics software to design a cylinder model with a diameter of 8 mm and a height of 12 mm, save it as a .stl file, import the .stl file into the Bioplotter RP layering software to layer the cuboid model, and save it as a .bpl file. Weigh 2g of PLGA particles with a molecular weight of 30kDa, monomer ratio PLA:PGA=50:50, and end-COOH, and put them into a stainless steel barrel with a stainless steel f...

Embodiment 2

[0064] The "calcium dihydrogen phosphate + α-tricalcium phosphate + calcium carbonate" system bone cement was selected and prepared by 3D printing with a molecular weight of 110kDa and a monomer ratio of PLA:PGA=50:50. The PLGA with terminal-COOH can form three-dimensional connected pores in situ structured network. Equipped with an appropriate device, the bone cement slurry is poured into the PLGA porous network to prepare a degradable polymer network / calcium phosphate bone cement composite bone repair material. The implementation steps include:

[0065] (1) Use the Magics modeling software to design a cylinder model with a diameter of 8mm and a height of 12mm, save it as a .stl format file, import the .stl file into the BioplotterRP layering software to layer the cuboid model, and save it as a .bpl format document. Weigh 2g of PLGA with a molecular weight of 110kDa, monomer ratio PLA:PGA=50:50, and end-COOH, and put it into a stainless steel barrel with a stainless steel fu...

Embodiment 3

[0075] The "amorphous calcium phosphate + calcium hydrogen phosphate dihydrate" system bone cement was selected, and the molecular weight was 30kDa prepared by 3D printing, the monomer ratio PLA:PGA=75:25, and the PLGA with terminal-COOH could form a three-dimensional connected porous structure network in situ. Equipped with an appropriate device, the bone cement slurry is poured into the PLGA porous network to prepare a degradable polymer network / calcium phosphate bone cement composite bone repair material. The implementation steps include:

[0076] (1) Use the Magics modeling software to design a cylinder model with a diameter of 8mm and a height of 12mm, save it as a .stl format file, import the .stl file into the BioplotterRP layering software to layer the cuboid model, and save it as a .bpl format document. Weigh 2g of PLGA with a molecular weight of 30kDa, monomer ratio PLA:PGA=75:25, and end-COOH, and put it into a stainless steel barrel with a stainless steel funnel. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com