Production method of micro-particle size precipitated barium sulfate

A technology for precipitating barium sulfate and a production method, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve the problems of large particle size, poor dispersibility, wide particle size distribution, etc. , to achieve the effects of improved mechanical properties, increased adhesion, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

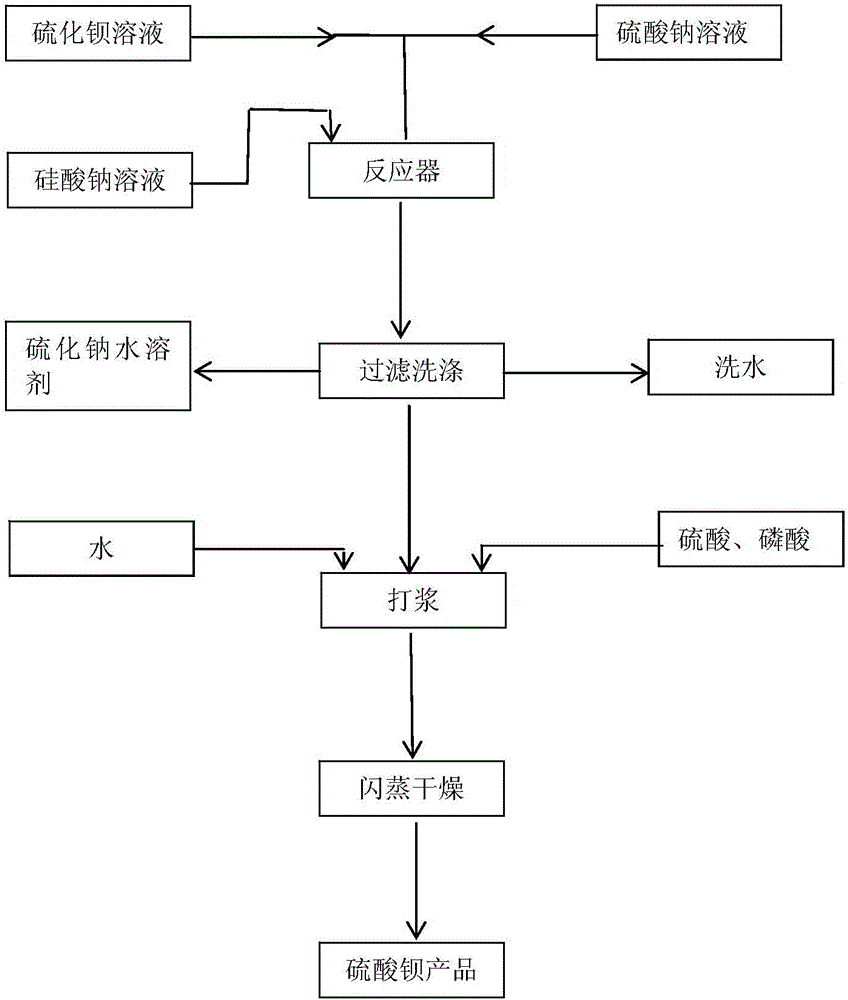

[0011] see figure 1 , the present invention focuses on the control of particle size in the production of precipitated barium sulfate, so that the barium sulfate particle size produced is small and the span is narrow, specifically comprising the following steps:

[0012] S100: Dissolve the crude barium sulfide black ash in water to make a clear barium sulfide solution with a concentration of 190g / L-200g / L and a temperature above 85°C for later use;

[0013] S200: Make sodium sulfate (glauber's salt) into a clear sodium sulfate solution with a concentration of 280-300g / L and a temperature above 85°C for later use.

[0014] In the present invention, the concentration of barium sulfide solution is 190-200g / L, the temperature is 85°C, the concentration of sodium sulfate solution is 280-300g / L, and the temperature is 85°C. In traditional production, the solution concentration is not controlled or the solution concentration is controlled low. The concentration of barium is usually 1...

Embodiment 2

[0023] This embodiment focuses on the application of barium sulfate worthwhile in Example 1. Adopt the barium sulfate prepared in embodiment 1 to prepare modified masterbatch, the high-purity barium sulfate obtained in embodiment 1 is mixed with silane coupling agent, stearic acid, polyethylene wax and resin, in every 100 kilograms of precipitated barium sulfate , add 2 kg of silane coupling agent, 1 kg of stearic acid, 5 kg of polyethylene wax and 15 kg of resin. Then put it into a high-speed mixer for high-speed mixing and heating. The heating temperature is 110°C. After heating for 20 minutes, cool it down. After cooling to 100°C, it is sent into the twin-screw extruder through the feeder. The temperature of the coils is controlled at 190°C, and finally they are extruded by a twin-screw extruder, pelletized and packaged. The prepared modified masterbatch has a particle diameter of 45mm, a relative density of 5 (15°C), a melting point of 1600°C, a Mohs hardness of 3.0, a wh...

Embodiment 3

[0025] This embodiment focuses on the application of barium sulfate worthwhile in Example 1. The method for preparing a composite material by using the barium sulfate prepared in Example 1, comprising: a. adding carbon fibers to 25 parts of 95% ethanol solvent, ultrasonically dispersing, adding acetic acid to adjust the pH to 4-5, adding 10 parts of silane coupling agent KH550, stirred for 8-15h, then washed with deionized water, and dried in vacuum; b. In the remaining 95% ethanol solvent, oxidized graphene oxide into graphene peroxide by glow discharge plasma technology; c. The graphene peroxide obtained by b is added to dimethylformamide (DMF), ultrasonicated for 2 to 3 hours, stirred, followed by adding 4-dimethylaminopyridine (DMAP), dicyclohexylcarbodiimide (DCC) and step a. The resulting carbon fibers were reacted at room temperature for 18-36h, then washed with deionized water, and dried in vacuum to obtain carbon fibers grafted with graphene peroxide; d. Adding fluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com