Preparation method of abamectin

A technology of abamectin and crude product, applied in the field of preparation of high-purity abamectin, can solve problems such as not suitable for large-scale production and application, no obvious removal effect of impurities, unsatisfactory removal effect of impurities, etc., and achieve low production cost , less investment in equipment, and improved elution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of crude abamectin.

[0034] The Streptomyces avermitilis strain was inoculated on the slant medium, and cultured for 10 days at 28° C. and an ambient relative humidity of 55%. Dig out the lawn from the inclined surface, insert it into the sterilized seed medium, and cultivate it for 48 hours at 28°C, the relative humidity of the environment is 55%, the cultivation speed is 200rpm, and the rotation radius is 50mm to obtain the seed solution. Inoculate the seed liquid with an inoculation amount of 5% by volume in a 50L fermenter equipped with fermentation medium. The tank temperature is 28°C, the relative humidity of the environment is 55%, the tank pressure is 0.05±0.01Mpa, the ventilation rate is 20L / min, and 200rpm is stirred. Fermentation 240h obtains the abamectin fermented liquid.

[0035] The preparation method of the slant medium is: glucose 15g, beef extract 3g, asparagine 0.5g, KH 2 PO 4 0.5g, agar 19g, add tap water to dissolve to 1000ml, pH v...

Embodiment 2

[0040] Get 10g Abamectin crude product, adopt 30ml of organic solvent dissolving according to every gram Abamectin crude product, select toluene as organic solvent, add 300ml toluene in Abamectin crude product, dissolve at 50 ℃, be mixed with crude product solution.

[0041]Take sodium sulfate, absolute ethanol and water and prepare the eluent, specifically: at a dissolution temperature of 25°C, add water to 90ml of absolute ethanol to 300ml to prepare an aqueous ethanol solution, then add 3g of sodium sulfate to the aqueous ethanol solution, Dissolve and prepare as eluent.

[0042] Elution was carried out in a countercurrent extraction equipment, the elution ratio of the crude product solution to the eluent was 1:1, the elution temperature was set at 25°C, the flow rate of the crude product solution was 7ml / min, and the flow rate of the eluent was 7ml / min , after the elution is complete, the eluate is obtained.

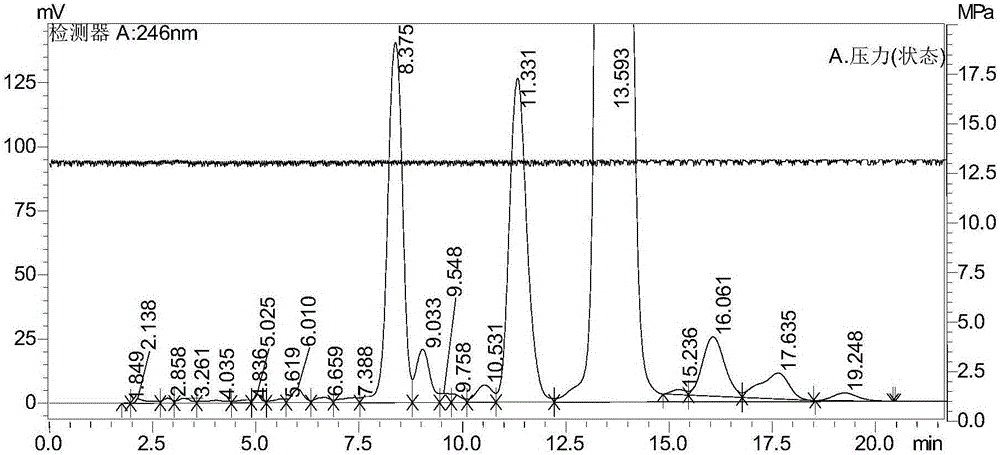

[0043] The eluate was concentrated and dried, and the dried pr...

Embodiment 3

[0045] Get 15g Abamectin crude product, adopt 30ml organic solvent dissolving according to every gram Abamectin crude product, select sec-butyl acetate as organic solvent, add 450ml sec-butyl acetate in Abamectin crude product, 50 ℃ dissolve, Prepared as a crude solution.

[0046] Take sodium carbonate, anhydrous methanol and water to prepare the eluent, specifically: at a dissolution temperature of 30°C, add water to 135ml of anhydrous methanol to 450ml to prepare methanol aqueous solution, and then add 4.5g of sodium carbonate to the methanol aqueous solution , dissolved clear, prepared as eluent.

[0047] Elution was carried out in a countercurrent extraction equipment, the elution ratio of the crude product solution to the eluent was 1:1, the elution temperature was set at 25°C, the flow rate of the crude product solution was 14ml / min, and the flow rate of the eluent was 14ml / min , after the elution is complete, the eluate is obtained.

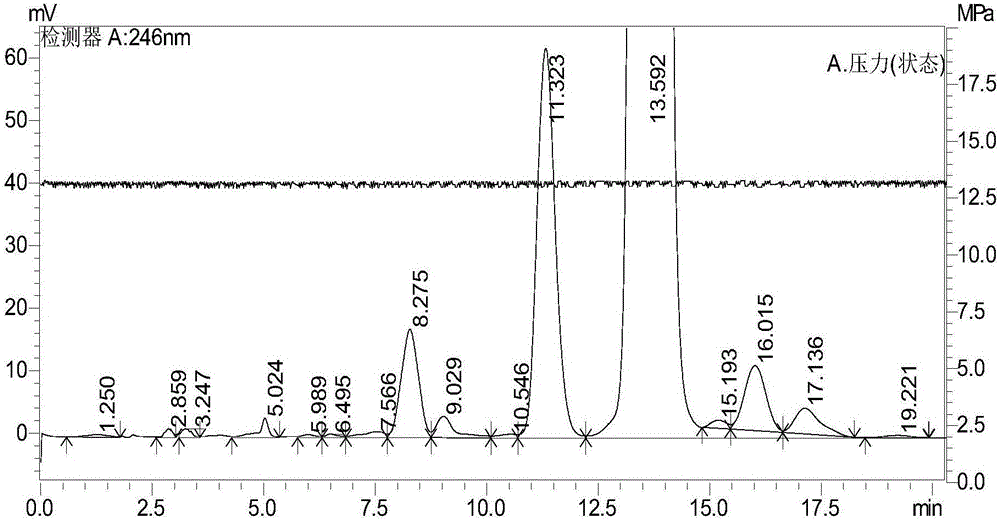

[0048] The eluate was concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com