Preparation method of macromolecular soil remediation agent

A soil remediation agent and polymer technology, applied in the field of agricultural pollution control, can solve the problems of difficult preparation, large-scale use, and unstable properties of nano-titanium dioxide, and achieve improved germination rate, stable molecular structure, and simple production control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

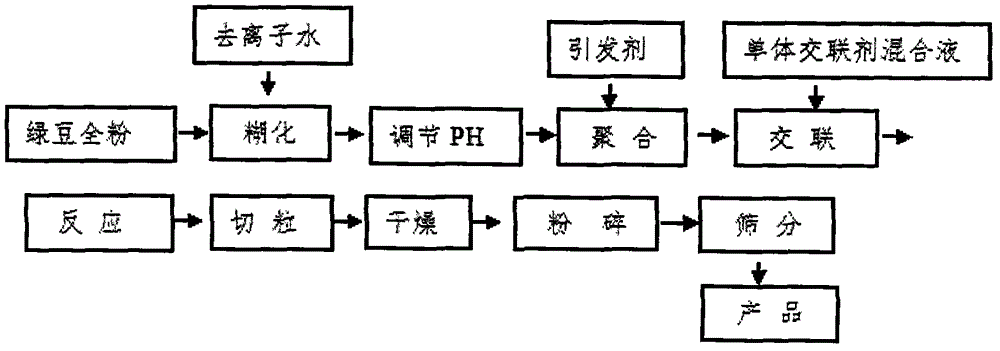

Image

Examples

Embodiment 1

[0030] A kind of preparation method of macromolecule soil remediation agent, concrete steps are as follows:

[0031] (1) Dissolve 150g of acrylic acid in 100ml of deionized water to prepare an aqueous solution of acrylic acid;

[0032] (2) 60g sodium hydroxide is dissolved in 150ml deionized water to prepare sodium hydroxide solution;

[0033] (3) At room temperature, slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution until the neutralization degree is 80%, and cool to room temperature;

[0034] (4) Add 0.05 g of cross-linking agent N-N' methylenebisacrylamide and 10 g of cross-linking agent methacryl hydroxyethyl ester to the mixed solution, stir evenly to obtain a mixed solution of monomer and cross-linking agent;

[0035] (5) Add 20 g of whole mung bean powder into a three-necked flask equipped with a stirrer, add 100 liters of distilled water, and stir and gelatinize in a constant temperature water bath at 90° C. for 15 minutes;

[003...

Embodiment 2

[0040] A kind of preparation method of macromolecule soil remediation agent, concrete steps are as follows:

[0041] (1) Dissolve 120g of acrylic acid in 50ml of deionized water to prepare an aqueous solution of acrylic acid;

[0042] (2) 60g sodium hydroxide is dissolved in 150ml deionized water to prepare sodium hydroxide solution;

[0043] (3) At room temperature, slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution until the neutralization degree is 80%, and cool to room temperature;

[0044] (4) Add 0.04 g of cross-linking agent N-N' methylene bisacrylamide and 8 g of cross-linking agent methacryl hydroxyethyl ester to the mixed solution, stir evenly to obtain a mixed solution of monomer and cross-linking agent;

[0045] (5) Add 20 g of mung bean whole powder into a three-neck flask equipped with a stirrer, add 100 g of distilled water, and stir and gelatinize in a constant temperature water bath at 80°C for 20 minutes;

[0046] (6) Adj...

Embodiment 3

[0050] A kind of preparation method of macromolecule soil remediation agent, concrete steps are as follows:

[0051] (1) Dissolve 120g of acrylic acid in 100ml of deionized water to prepare an aqueous solution of acrylic acid;

[0052] (2) 60g sodium hydroxide is dissolved in 150ml deionized water to prepare sodium hydroxide solution;

[0053] (3) At room temperature, slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution until the neutralization degree is 80%, and cool to room temperature;

[0054] (4) Add 0.04 g of cross-linking agent N-N' methylenebisacrylamide and 10 g of cross-linking agent methacryl hydroxyethyl ester to the mixed solution, stir evenly to obtain a mixed solution of monomer and cross-linking agent;

[0055] (5) Add 15g of mung bean whole powder into a three-neck flask equipped with a stirrer, add 100g of distilled water, and stir and gelatinize in a constant temperature water bath at 80°C for 30min;

[0056] (6) Adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com