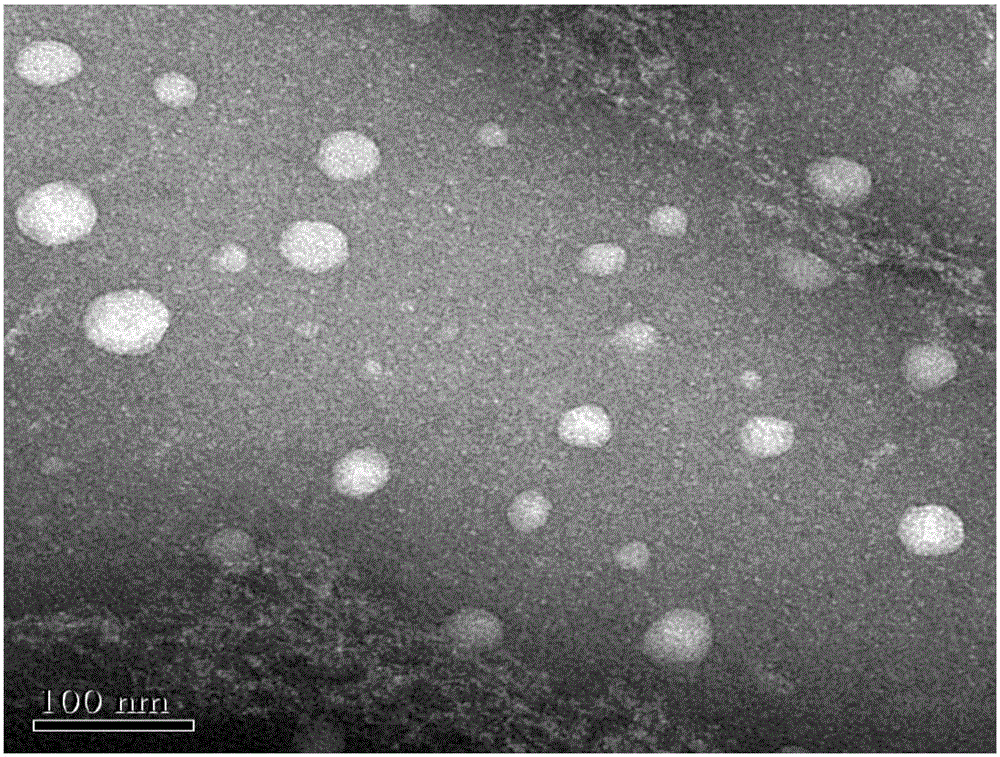

Hemicellulose-based light response nano hydrogel and preparation method and application thereof

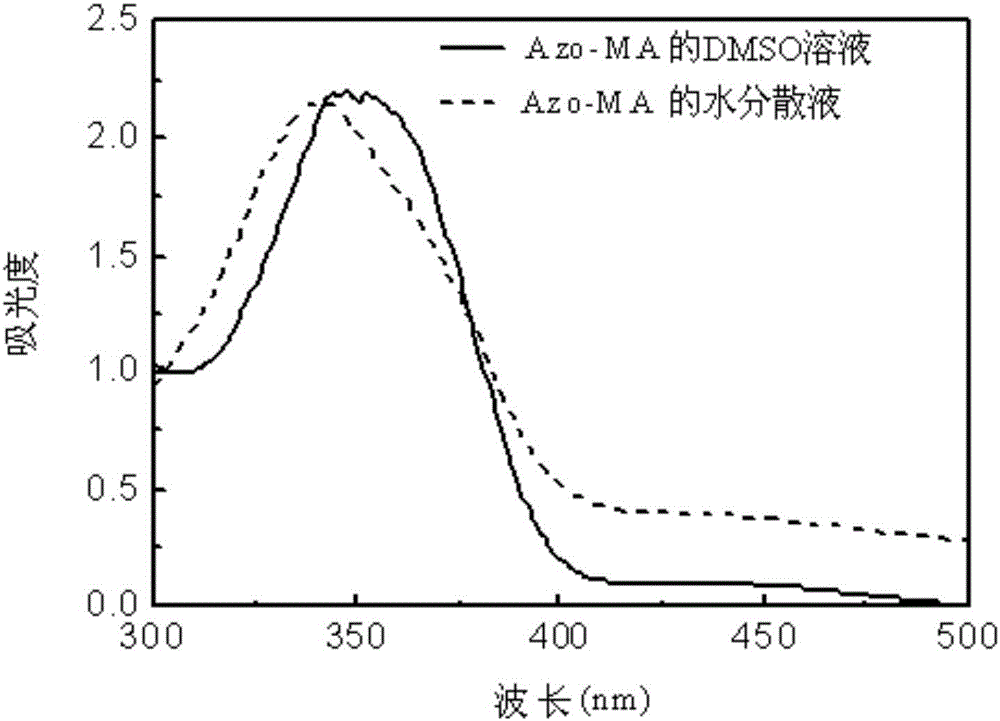

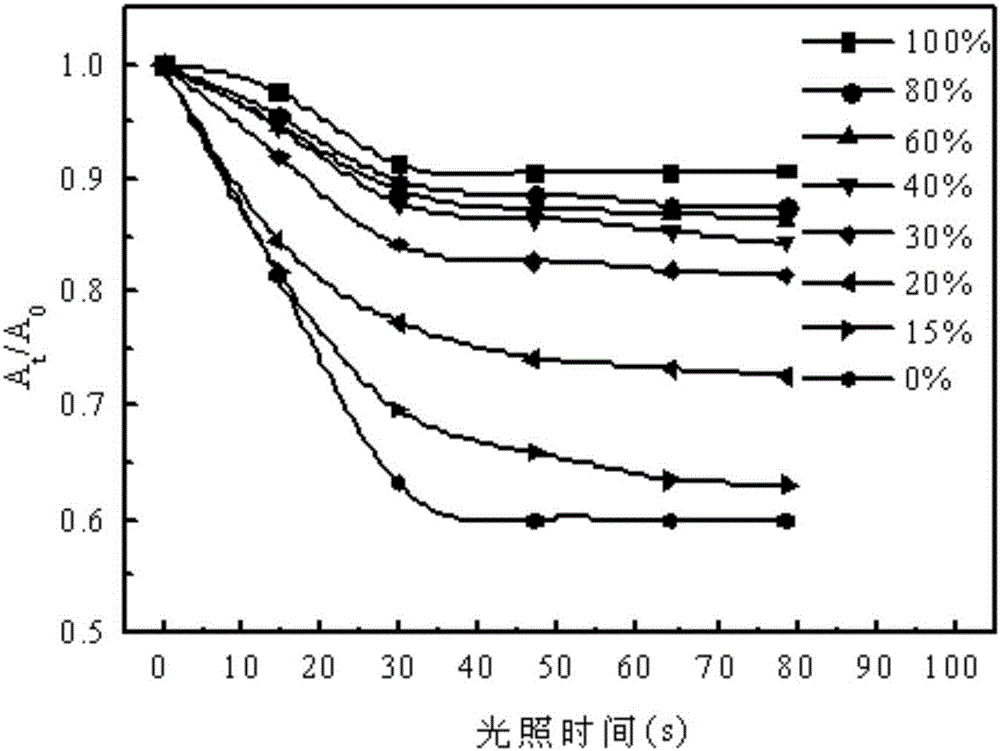

A nano-hydrogel and hemicellulose technology is applied in the field of hemicellulose-based light-responsive nano-hydrogel and its preparation, which can solve the problems of long response time, unenvironmental protection, non-compliance, etc., and achieves good application prospects, biological Good compatibility and high photoresponse efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Into the three-necked flask, pass nitrogen gas, put 40g 1,6-dibromohexane, 12g K 2 CO 3 Add 0.5g KI and 0.5g KI into 125ml acetone, stir well and then slowly heat up to above 60°C; dissolve 4.95g 4-hydroxyazobenzene in acetone, add dropwise to the above reaction system with a constant pressure funnel, drop After adding, it was heated to reflux for 24h. Filter while hot to remove the inorganic salt (filter residue) in the system, wash with acetone and collect the filtrate, evaporate and concentrate the filtrate with a rotary evaporator, add dropwise to cold ethanol to precipitate, filter, and finally recrystallize the solid after drying to obtain yellow flakes The solid is the desired 4-omega-bromohexyloxyazobenzene.

[0031] (2) Under heating conditions, dissolve 1 g of hemicellulose in anhydrous DMSO until completely dissolved into a light yellow transparent solution, then cool down to room temperature, and pass through N 2 Then add 100 μL of 10% alkali solution...

Embodiment 2

[0034] (1) Into the three-necked flask, feed nitrogen, put 15g 1,6-dibromohexane, 4.5g K 2 CO 3 Add 0.2g KI and 0.2g KI into 125mL acetone, stir well and then slowly heat up to above 60°C; dissolve 4.95g 4-hydroxyazobenzene in acetone, and add dropwise to the above reaction system with a constant pressure funnel, dropwise After adding, it was heated to reflux for 24h. Filter while hot to remove the inorganic salt (filter residue) in the system, wash with acetone and collect the filtrate, evaporate and concentrate the filtrate with a rotary evaporator, add dropwise to cold ethanol to precipitate, filter, and finally recrystallize the solid after drying to obtain yellow flakes The solid is the desired 4-omega-bromohexyloxyazobenzene.

[0035] (2) Under heating conditions, dissolve 1 g of hemicellulose in anhydrous DMSO until completely dissolved into a light yellow transparent solution, then cool down to room temperature, and pass through N 2 Then add 100 μL alkali solution w...

Embodiment 3

[0038] (1) Into the three-necked flask, feed nitrogen, mix 40g 1,6-dibromohexane, 12.1g K 2 CO 3 Add 0.5g KI and 0.5g KI into 125ml acetone, stir well and then slowly heat up to above 60°C; dissolve 4.95g 4-hydroxyazobenzene in acetone, add dropwise to the above reaction system with a constant pressure funnel, drop After adding, it was heated to reflux for 24h. Filter while hot to remove the inorganic salt (filter residue) in the system, wash with acetone and collect the filtrate, evaporate and concentrate the filtrate with a rotary evaporator, add dropwise to cold ethanol to precipitate, filter, and finally recrystallize the solid after drying to obtain yellow flakes The solid is the desired 4-omega-bromohexyloxyazobenzene.

[0039] (2) Under heating conditions, dissolve 1 g of hemicellulose in anhydrous DMSO until completely dissolved into a light yellow transparent solution, then cool down to room temperature, and pass through N 2 Then add 100 μL alkali solution with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com