Non-self-consumption electric arc smelting preparing method of tungsten alloy

An arc smelting, non-consumable technology, applied in the field of non-consumable arc smelting and preparation of high-density, ultra-high specific gravity tungsten alloys, can solve the problems of low bulk density of tungsten powder, complicated electrode preparation, introduction of carbide impurities, etc. , to achieve the effect of reducing the difficulty and porosity of arc melting, easy experimental conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

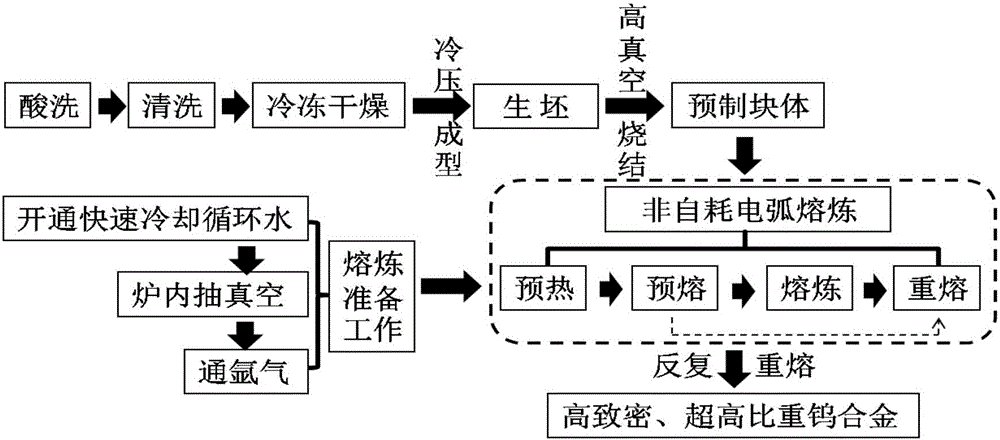

Method used

Image

Examples

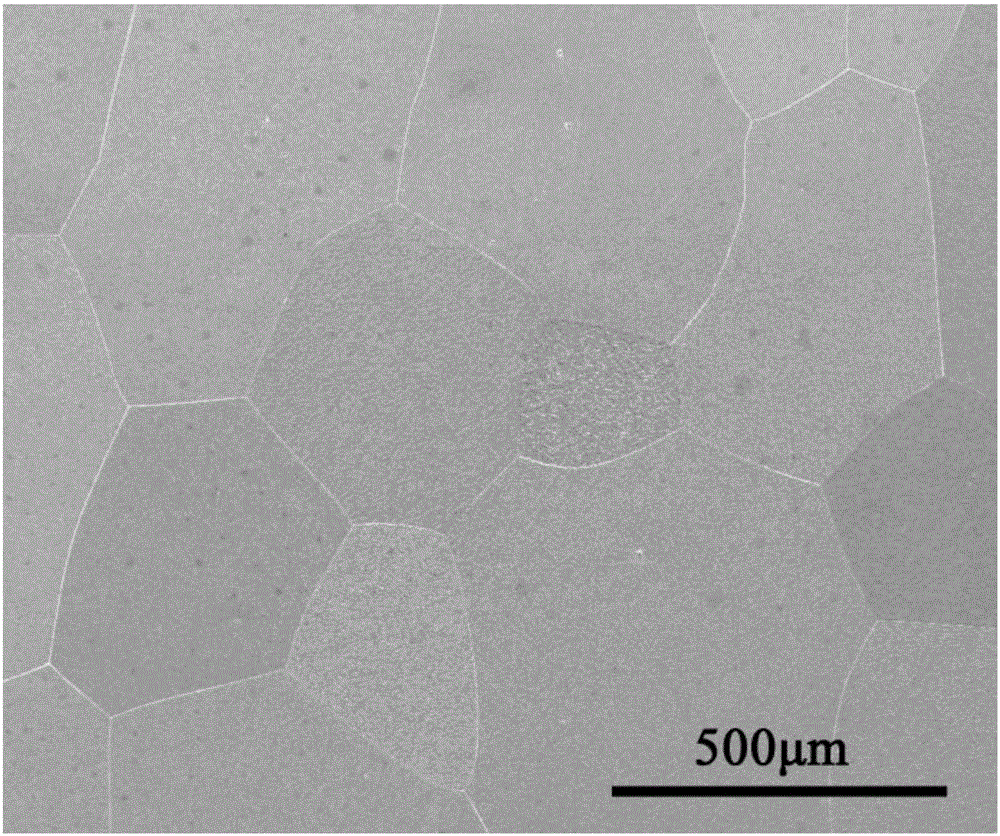

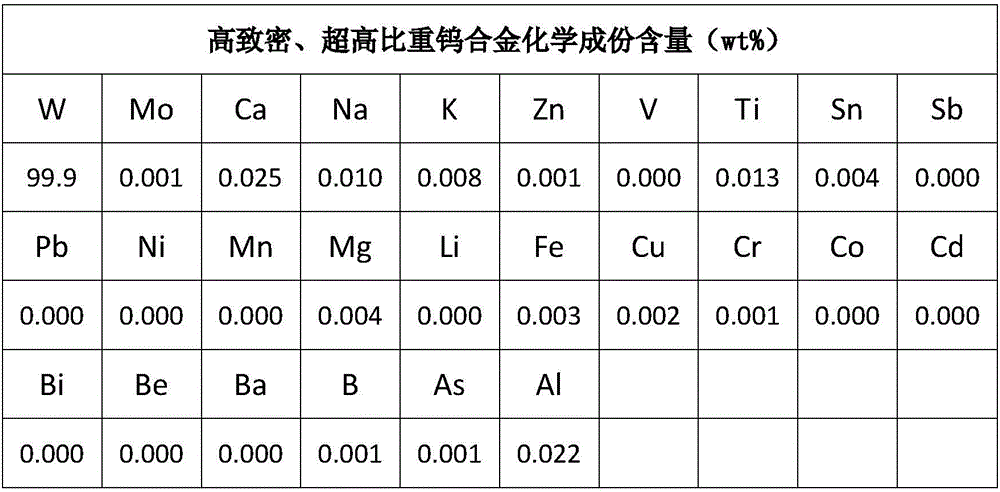

Embodiment 1

[0038] An ultra-high specific gravity tungsten alloy with a density of 99.2% is prepared (the specific gravity content of tungsten is 99.9%, and the specific gravity is 19.11). The preparation process is sequentially processed by tungsten powder pickling, cleaning, freeze-drying, cold pressing, high vacuum sintering to obtain a prefabricated block, and non-consumable arc melting of the alloy to obtain the tungsten alloy. Among them, the process of non-consumable arc melting includes preheating, premelting, melting, multiple remelting, etc. The specific steps are as follows:

[0039] 1. Pickling, cleaning and freeze-drying of tungsten powder:

[0040] Use dilute hydrochloric acid with a concentration of 3mol / L to pickle tungsten powder (with a particle size of 1-20μm) with a specific gravity of 99.0% for 60 minutes, then remove the upper cleaning solution, and use a resistivity ≥ 2.0×10 6 Wash with Ω·cm deionized water until pH ≥ 4, and then use freeze-drying equipment to fre...

Embodiment 2

[0048] An ultra-high specific gravity tungsten alloy with a density of 98.1% is prepared (the specific gravity content of tungsten is 99.7%, and the specific gravity is 18.89). The preparation process is sequentially processed by tungsten powder pickling, cleaning, freeze-drying, cold pressing, high vacuum sintering to obtain a prefabricated block, and non-consumable arc melting of the alloy to obtain the tungsten alloy. Among them, the process of non-consumable arc melting includes preheating, premelting, melting, multiple remelting, etc. The specific steps are as follows:

[0049] 1. Pickling, cleaning and freeze-drying of tungsten powder:

[0050] Use dilute hydrochloric acid with a concentration of 3mol / L to pickle tungsten powder (with a particle size of 1-20μm) with a specific gravity of 98.5% for 30 minutes, then remove the upper cleaning solution, and use a resistivity ≥ 2.0×10 6 Wash with Ω·cm deionized water until pH ≥ 4, and then use freeze-drying equipment to fre...

Embodiment 3

[0058] An ultra-high specific gravity tungsten alloy with a density of 99.0% is prepared (the specific gravity content of tungsten is 99.9%, and the specific gravity is 19.07). The preparation process is sequentially processed by tungsten powder pickling, cleaning, freeze-drying, cold pressing, high vacuum sintering to obtain a prefabricated block, and non-consumable arc melting of the alloy to obtain the tungsten alloy. Among them, the process of non-consumable arc melting includes preheating, premelting, melting, multiple remelting, etc. The specific steps are as follows:

[0059] 1. Pickling, cleaning and freeze-drying of tungsten powder:

[0060] Use dilute hydrochloric acid with a concentration of 1mol / L to pickle tungsten powder (with a particle size of 1-20μm) with a specific gravity of 98.5% for 60 minutes, then remove the upper cleaning solution, and use a resistivity ≥ 2.0×10 6 Wash with Ω·cm deionized water until pH ≥ 4, and then use freeze-drying equipment to fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com