Lithium battery graphene conductive paste and preparation method thereof

A technology of conductive paste and graphene, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of difficult dispersion of conductive agents and poor conductivity, so as to improve charge and discharge efficiency, increase carrier concentration, and protect integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

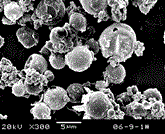

Image

Examples

Embodiment 1

[0057] (1) Mix 10 parts by weight of graphite powder and 0.5 parts by weight of activator lithium carboxylate evenly at 200-250°C, then send them into a high-speed centrifugal jet mill, and generate high-speed swirling flow in the pulverization chamber of the jet micromachine , causing intense collision and friction between the graphite powder particles, thereby pulverizing and homogenizing, and making the graphite powder particles undergo activation modification;

[0058] (2) Combine the material obtained in step (1) with 0.1 parts by weight of carbon nanotubes, 1 part by weight of dispersant styrene maleimide resin, 0.1 parts by weight of micron-scale accelerator vanadium pentoxide, 0.2 parts by weight The colloidal material gelatin in parts by weight is dispersed and stripped in a sand mill, and is circularly ground under the shear force and friction of the sand mill. The micron-scale accelerator acts as a microscopic force transmission medium to make graphite be stripped in...

Embodiment 2

[0063] (1) Mix 10 parts by weight of natural flake graphite and 2 parts by weight of activator sodium carboxylate evenly at 200-250°C, then send them into a flat jet mill, and generate high-speed whirl in the flat jet mill pulverization chamber. The flow causes intense collision and friction between the graphite powder particles, thereby pulverizing and homogenizing, so that the graphite powder particles can be activated and modified;

[0064] (2) The material obtained in step (1) is mixed with 0.2 parts by weight of carbon nanotubes, 0.5-1 parts by weight of dispersant sodium lauryl sulfate, and 0.05 parts by weight of accelerator 2-5 micron diboride Titanium and 0.2 parts by weight of the colloidal material xanthan gum are dispersed and stripped in a planetary ball mill, and are cyclically ground under the shear force and friction of the grinding unit. The micron-scale accelerator acts as a microscopic force transmission medium to make the graphite stripped into graphene. At...

Embodiment 3

[0069] (1) Mix 8 parts by weight of expanded graphite and 1 part by weight of activator lithium carboxylate evenly at 200-250°C, and then send them into a circulating tube jet mill, where high-speed The swirling flow causes intense collision and friction between the graphite powder particles, thereby pulverizing and homogenizing the graphite powder particles for activation and modification;

[0070] (2) Combine the material obtained in step (1) with 0.3 parts by weight of carbon nanotubes, 0.5 parts by weight of dispersant sodium dodecylbenzenesulfonate, 0.04 parts by weight of accelerator micron-sized boron oxide, 0.2 parts by weight Part of the colloidal material guar gum is dispersed and stripped in the agitating grinder, and is circularly ground under the action of the shear force and friction of the agitating grinder. The micron-scale accelerator acts as a microcosmic force transmission medium to make the graphite be stripped into graphene, and at the same time Micron-sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com