A three-dimensional limn 2 o 4 Preparation method of thin-film positive electrode and three-dimensional all-solid-state thin-film lithium-ion battery

A lithium-ion battery and positive electrode technology, applied in the field of all-solid-state thin-film lithium-ion batteries, can solve the problems of morphology control and mass production, difficulty in maintaining three-dimensional nanostructures, difficulty in uniform deposition of positive electrode materials, etc., and achieve excellent rate performance And cycle stability, increase the electrochemical reaction area, improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Three-dimensional LiMn 2 o 4 A method for preparing a thin film positive electrode, comprising

[0030] (1) LiMn with excess Li 2 o 4 The material is used as the target material, the stainless steel foil coated with metal layer is used as the substrate, and the magnetron sputtering vacuum chamber is evacuated to 6×10 -5 Pa, heat the substrate to 300°C, feed 36sccm argon and 4sccm oxygen, and adjust the gas pressure in the chamber to 1Pa;

[0031] (2) Set the DC sputtering power to 4.3W / cm 2 , the target base distance is 80mm, and the pre-sputtering is 10min to clean the impurities on the target surface. The sputtering time is 3h, and the three-dimensional LiMn can be directly obtained on the substrate. 2 o 4 film.

[0032] (3) The three-dimensional LiMn obtained above 2 o 4 Thin film annealing treatment, annealing temperature 700°C, annealing time 2h.

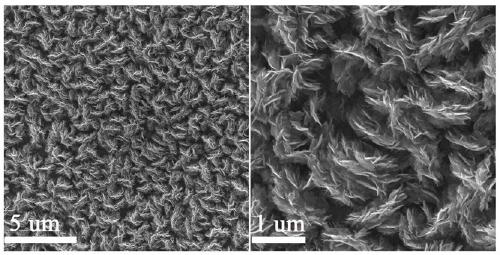

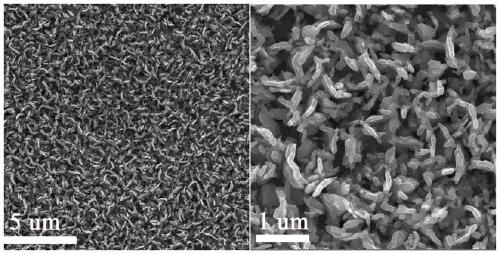

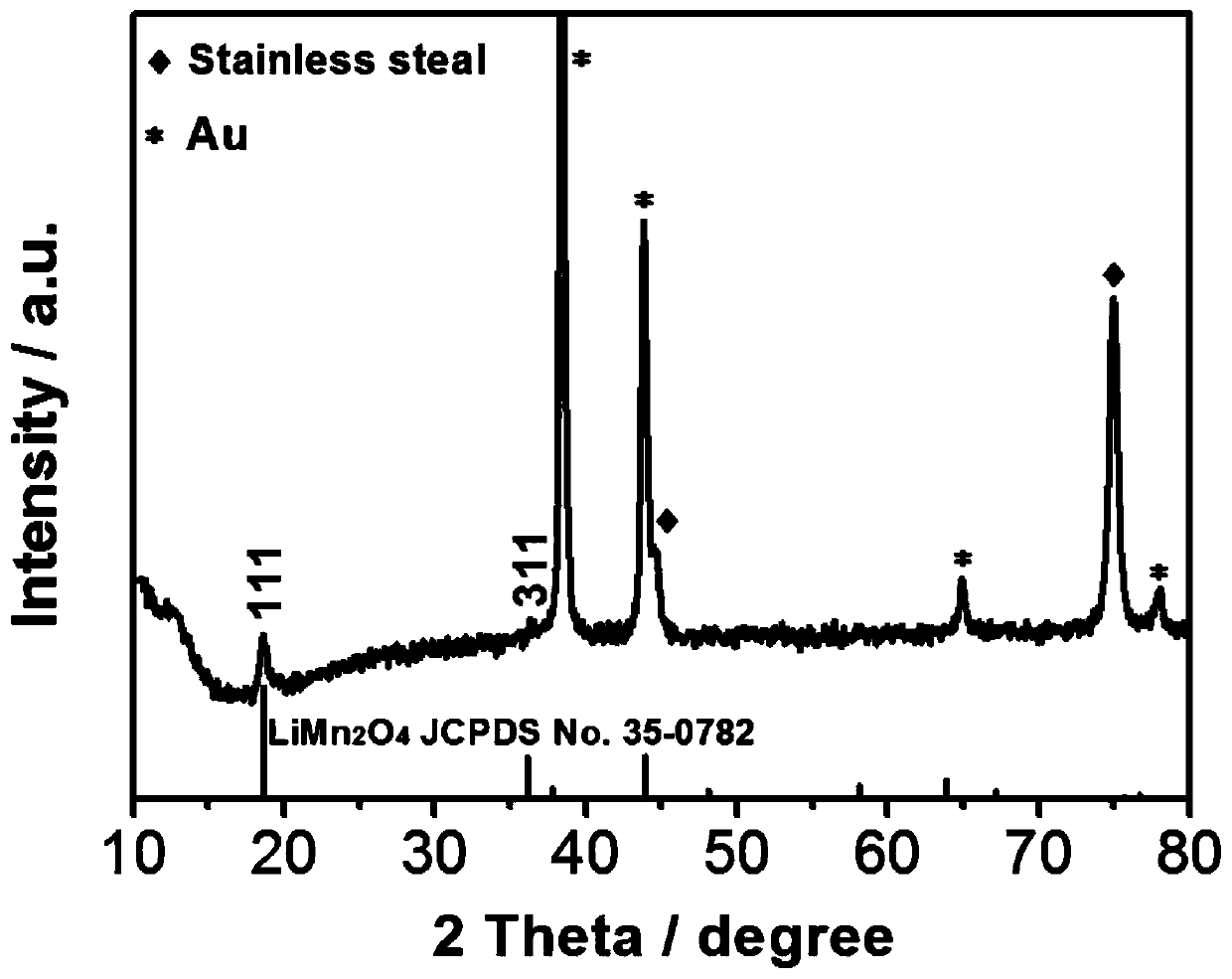

[0033] figure 1 It is a three-dimensional LiMn sputtered directly at 300 °C 2 o 4 SEM image...

Embodiment 2

[0041] This embodiment provides a LiMn for three-dimensional all-solid-state ion battery 2 o 4 The anode material is obtained by directly sputtering with a DC power source to obtain a three-dimensional anode film with a thickness of 1.3 μm.

[0042] Preparation method: (1) LiMn with excess Li 2 o 4 The material is used as the target, the stainless steel foil coated with gold layer is used as the substrate, and the magnetron sputtering vacuum chamber is evacuated to 6×10 -5 Pa, heat the substrate to 300°C, feed 36sccm argon and 4sccm oxygen, and adjust the gas pressure in the chamber to 1Pa;

[0043] (2) Set the DC sputtering power to 4.3W / cm 2 , the target base distance is 80mm, and the pre-sputtering is 10 minutes to clean the impurities on the target surface. The sputtering time is 3h, and the three-dimensional LiMn can be directly obtained on the substrate. 2 o 4 film;

[0044] (3) The three-dimensional LiMn obtained above 2 o 4 Thin film annealing treatment, annea...

Embodiment 3

[0049] This embodiment provides a LiMn for three-dimensional all-solid-state ion battery 2 o 4 The anode material is obtained by directly sputtering with a DC power source to obtain a three-dimensional anode film with a thickness of 1.3 μm.

[0050] Preparation method: (1) LiMn with excess Li 2 o 4 The material is used as the target, the stainless steel foil coated with gold layer is used as the substrate, and the magnetron sputtering vacuum chamber is evacuated to 6×10 -5 Pa, heat the substrate to 300°C, feed 36sccm argon and 4sccm oxygen, and adjust the gas pressure in the chamber to 1Pa;

[0051] (2) Set the DC sputtering power to 4.3W / cm 2 , target base distance 80mm, pre-sputtering for 10 minutes to clean the impurities on the target surface, sputtering time is 2h, then adjust the temperature to 600°C, sputtering time 1h, other conditions remain unchanged, can be obtained directly on the substrate 3D LiMn 2 o 4 film.

[0052] (3) The three-dimensional LiMn obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com