Preparation method of konjac glucomannan gel microspheres

A technology of konjac glucomannan and gel microspheres, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of difficulty in obtaining uniform beads, complex screening procedures, and large manpower and material resources. Achieve the effect of maintaining biological activity and biological stability, simple preparation process and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of konjac glucomannan gel microspheres, comprising the following steps:

[0031] Step 1. Add 1 g of konjac glucomannan to 25 mL of ethanol aqueous solution, and stir at 40° C. for 1 hour to obtain a konjac glucomannan dispersion; the volume ratio of ethanol and water in the ethanol aqueous solution is 1:25 ;

[0032] Step 2: Add the konjac glucomannan dispersion into 30mL of liquid paraffin, and add 0.6mL of Span-80 and 0.8g of sodium hydroxide to the liquid paraffin, and stir at 40°C for 1 hour to obtain konjac glucomannan Mannan emulsion;

[0033] Step 3, adding 1 mL of 0.5 mol / L hydrochloric acid and 1 mL of glutaraldehyde to the konjac glucomannan emulsion, stirring and reacting for 8 hours to obtain gel microspheres;

[0034] Step 4, washing the gel microspheres with cyclohexane, ethanol, and pure water until neutral, and freeze-drying to obtain konjac glucomannan gel microspheres.

Embodiment 2

[0036] A preparation method of konjac glucomannan gel microspheres, comprising the following steps:

[0037] Step 1: Add 3 g of konjac glucomannan into 35 mL of aqueous ethanol, and stir at 500 r / min for 3 hours at 60° C. to obtain a dispersion of konjac glucomannan; the volume ratio of ethanol and water in the aqueous ethanol is 1:30;

[0038] Step 2. Add the konjac glucomannan dispersion into 60mL of liquid paraffin, and add 1.2mL of Span-80 and 2g of sodium hydroxide into the liquid paraffin, and stir at 500r / min at 60°C for 3 hours. Obtain konjac glucomannan emulsion;

[0039] Step 3, adding 5 mL of 1.5 mol / L hydrochloric acid and 5 mL of glutaraldehyde to the konjac glucomannan emulsion, stirring and reacting at 500 r / min for 12 hours to obtain gel microspheres;

[0040] Step 4, washing the gel microspheres with cyclohexane, ethanol, and pure water until neutral, and freeze-drying to obtain konjac glucomannan gel microspheres.

Embodiment 3

[0042] A preparation method of konjac glucomannan gel microspheres, comprising the following steps:

[0043] Step 1: Add 1.2 g of konjac glucomannan into 30 mL of aqueous ethanol, and stir at 600 r / min for 2 hours at 50° C. to obtain a dispersion of konjac glucomannan; the volume of ethanol and water in the aqueous ethanol solution The ratio is 3:27;

[0044]Step 2. Add the konjac glucomannan dispersion to 45mL of liquid paraffin, and add 0.9mL of Span-80 and 1.2g of sodium hydroxide to the liquid paraffin, and stir at 50°C at 600r / min for 2 hours , to obtain konjac glucomannan emulsion;

[0045] Step 3, adding 3 mL of 1 mol / L hydrochloric acid and 3 mL of glutaraldehyde to the konjac glucomannan emulsion, stirring and reacting at 600 r / min for 10 hours to obtain gel microspheres;

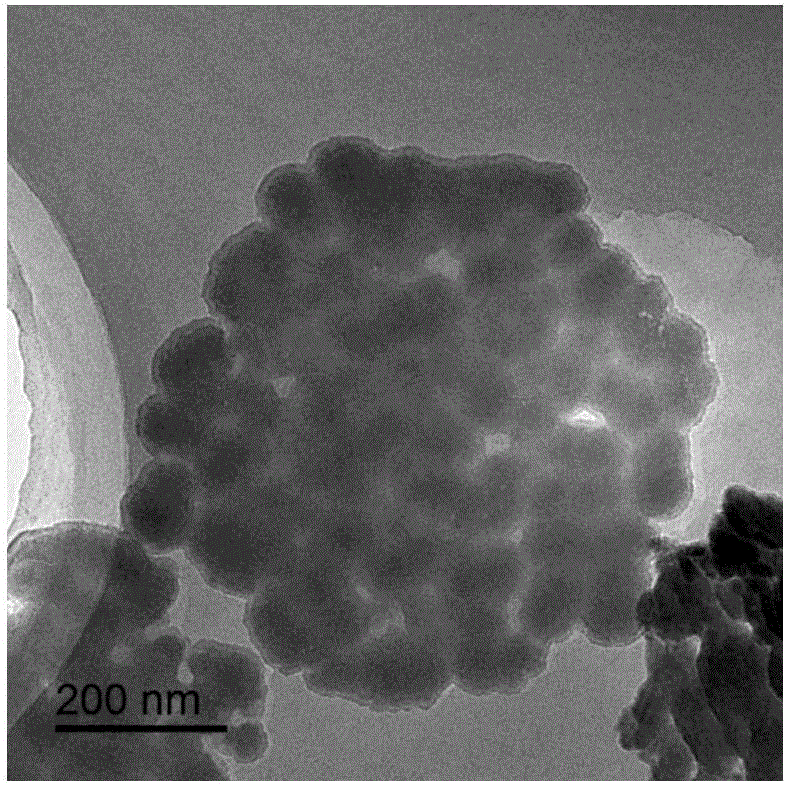

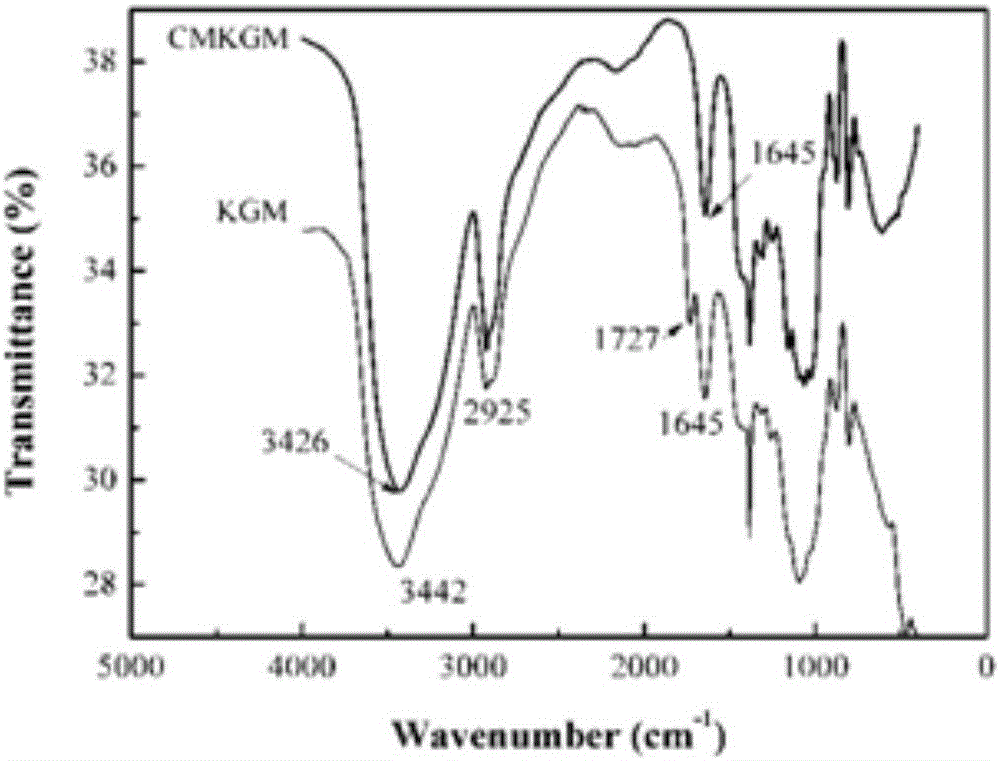

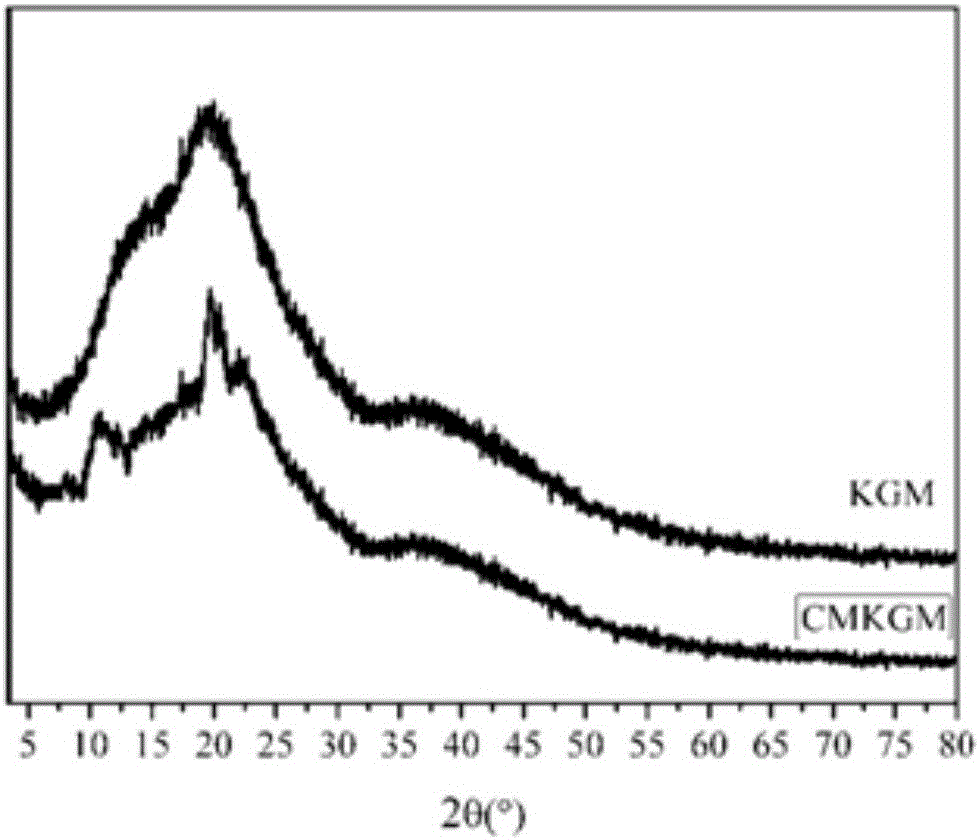

[0046] Step 4, washing the gel microspheres with cyclohexane, ethanol, and pure water to neutrality, and freeze-drying to obtain konjac glucomannan gel microspheres; figure 1 The transmission el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com