Preparation method and film of graphene/silver nanowire composite film with high thermal conductivity and high electrical conductivity

A technology of silver nanowires and composite films, which is applied in the field of preparation of graphene composite films, can solve the problems of insufficient stability of graphene performance, lack of simple operation, high equipment requirements, etc., and achieve uniform layering, high thermal conductivity and electrical conductivity , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the high thermal conductivity described in the present embodiment, the highly conductive graphene / silver nanowire composite film is specifically carried out according to the following steps:

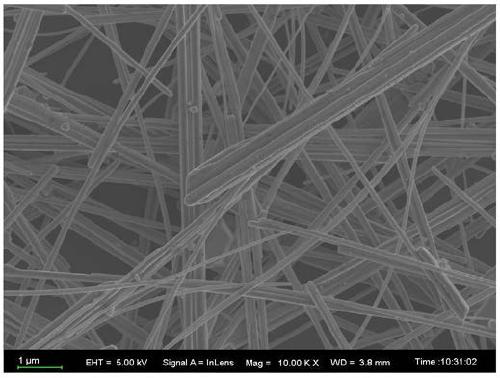

[0035] 1) Preparation of silver nanowires: 0.32mg FeCl 3 Dissolve in 20ml of ethylene glycol solution, then add 0.369g of polyvinylpyrrolidone to the solution, and magnetically stir for 10min; 0.34g of AgNO 3 Dissolve in 20ml ethylene glycol, stir well; use syringe pump to dissolve FeCl 3 The solution was slowly added to the AgNO 3 solution, fully stirred; inject the mixed solution into the reaction kettle, and react at 160°C for 2.5h to obtain the silver nanowire solution;

[0036] The FeCl 3 The molar concentration of the solution is 0.1mM / L; the molar concentration of the solution of the polyvinylpyrrolidone is 0.15M / L; the AgNO 3 The molar concentration of the solution is 0.1M / L; the injection rate of the syringe pump is 1mL / min;

[0037] Dispers...

Embodiment 2

[0051] The preparation method of the high thermal conductivity described in the present embodiment, the highly conductive graphene / silver nanowire composite film is specifically carried out according to the following steps:

[0052] 1) Preparation of silver nanowires: 0.32mg FeCl 3 Dissolve in 20ml of ethylene glycol solution, then add 0.369g of polyvinylpyrrolidone to the solution, and magnetically stir for 10min; 0.34g of AgNO 3 Dissolve in 20ml ethylene glycol, stir well; use syringe pump to dissolve FeCl 3 The solution was slowly added to the AgNO 3 solution, fully stirred; inject the mixed solution into the reaction kettle, and react at 160°C for 2.5h to obtain the silver nanowire solution;

[0053] The FeCl 3 The molar concentration of the solution is 0.1mM / L; the molar concentration of the solution of the polyvinylpyrrolidone is 0.15M / L; the AgNO 3 The molar concentration of the solution is 0.1M / L; the injection rate of the syringe pump is 0.5mL / min;

[0054] Dispe...

Embodiment 3

[0065] The preparation method of the high thermal conductivity described in the present embodiment, the highly conductive graphene / silver nanowire composite film is specifically carried out according to the following steps:

[0066] 1) Preparation of silver nanowires: 0.32mg FeCl 3 Dissolve in 20ml of ethylene glycol solution, then add 0.369g of polyvinylpyrrolidone to the solution, and magnetically stir for 10min; 0.34g of AgNO 3 Dissolve in 20ml ethylene glycol, stir well; use syringe pump to dissolve FeCl 3 The solution was slowly added to the AgNO 3 solution, fully stirred; inject the mixed solution into the reaction kettle, and react at 160°C for 2.5h to obtain the silver nanowire solution;

[0067] The FeCl 3 The molar concentration of the solution is 0.1mM / L; the molar concentration of the solution of the polyvinylpyrrolidone is 0.15M / L; the AgNO 3 The molar concentration of the solution is 0.1M / L; the injection rate of the syringe pump is 0.8mL / min;

[0068] Dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com