Mannich base quaternary ammonium salt compound and preparation method thereof

A technology of quaternary ammonium salt compound and Mannich base, which is applied in the field of metal preservatives, Mannich base quaternary ammonium salt compound and its preparation, can solve the problems of poor corrosion inhibition effect, poor acid solubility, high toxicity, etc. Achieve easy adsorption, increase water solubility, and inhibit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

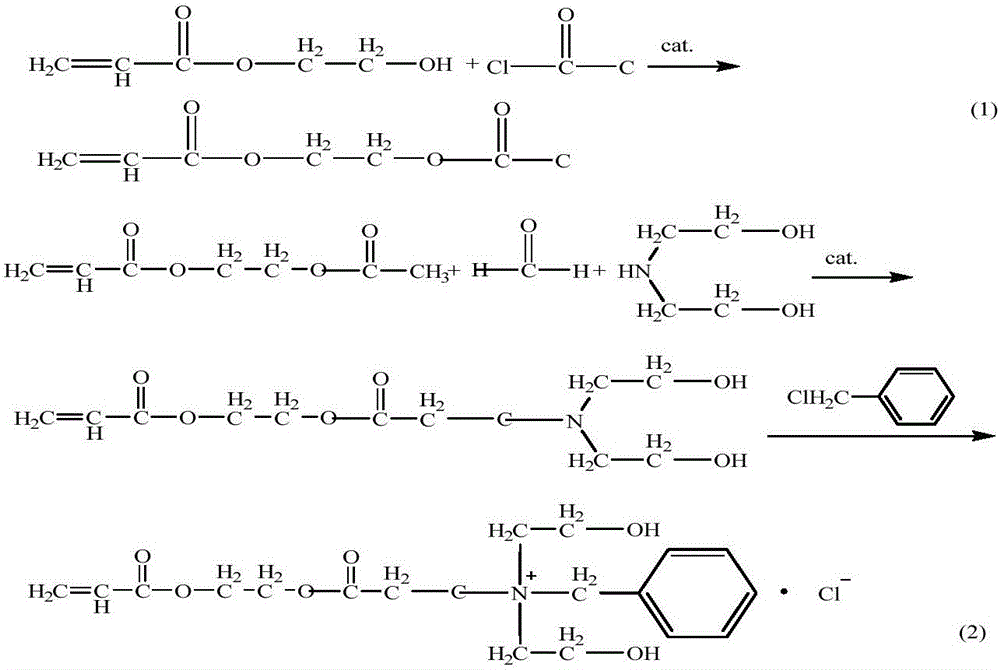

[0027] (1) see figure 1 , add hydroxyethyl acrylate and triethylamine to a 500mL three-neck flask equipped with an electric stirrer, a reflux condenser and a constant pressure dropping funnel, slowly add acetyl chloride dropwise while stirring in an ice-water bath, within 0.5h After the dropwise addition, react at 10°C for 3 hours to obtain a mixture of ethylene glycol acetate and triethylamine hydrochloride, wash with ether 2 to 3 times, remove triethylamine hydrochloride by suction filtration, and distill off Ethyl ether is used to produce ethylene glycol acetate, wherein the ratio of substances of hydroxyethyl acrylate, acetyl chloride and triethylamine is 1:1:0.5.

[0028] (2) Add 30% formaldehyde solution and diethylamine in a 500mL three-necked flask, and add deionized water (the volume ratio of deionized water to formaldehyde solution is 15:1), and use 10% hydrochloric acid solution Adjust pH=3.5, reflux reaction at 60°C for 1 hour, slowly add ethylene acetate acrylic ...

Embodiment 2

[0030] (1) Add hydroxyethyl acrylate and triethylamine to a 500mL three-necked flask equipped with an electric stirrer, a reflux condenser, and a constant pressure dropping funnel, and slowly add acetyl chloride dropwise while stirring in an ice-water bath. After the dropwise addition is completed, react at 20°C for 2 hours to obtain a mixture of ethylene glycol acetate and triethylamine hydrochloride, wash with ether 2 to 3 times, remove triethylamine hydrochloride by suction filtration, and distill Ethyl ether is removed to obtain ethylene acetate of acrylate to obtain ethylene acetate of acrylate, wherein the mass ratio of hydroxyethyl acrylate, acetyl chloride and triethylamine is 1:1:0.7.

[0031] (2) Add formaldehyde solution and diethanolamine with a mass fraction of 40% in a 500mL three-necked flask, and add an appropriate amount of solvent deionized water (the volume ratio of deionized water to formaldehyde solution is 20:1), and use a mass fraction of 10% hydrochlori...

Embodiment 3

[0033](1) Add hydroxyethyl acrylate and triethylamine to a 500mL three-necked flask equipped with an electric stirrer, a reflux condenser and a constant pressure dropping funnel, and slowly add acetyl chloride dropwise while stirring in an ice-water bath. After the internal drop is completed, react at 0°C for 1 hour to obtain a mixture of ethylene glycol acetate and triethylamine hydrochloride, wash with ether 2 to 3 times, remove triethylamine hydrochloride by suction filtration, and distill Ethyl ether is removed to obtain ethylene acetate of acrylate to obtain ethylene acetate of acrylate, wherein the mass ratio of hydroxyethyl acrylate, acetyl chloride and triethylamine is 1:1.2:1.

[0034] (2) In a 500mL three-necked flask, add paraformaldehyde solution and diethanolamine with a mass fraction of 45%, and add an appropriate amount of solvent absolute ethanol (the volume ratio of deionized water to paraformaldehyde solution is 20:1), and use The hydrochloric acid solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com