Engineered Escherichia coli and method of synthesis of catalyzing fumaric acid from maleic acid in presence of Engineered Escherichia coli

A technology of Escherichia coli and engineering bacteria, applied in microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of reducing the conversion rate and purity of fumaric acid, and achieve the effect of improving expression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

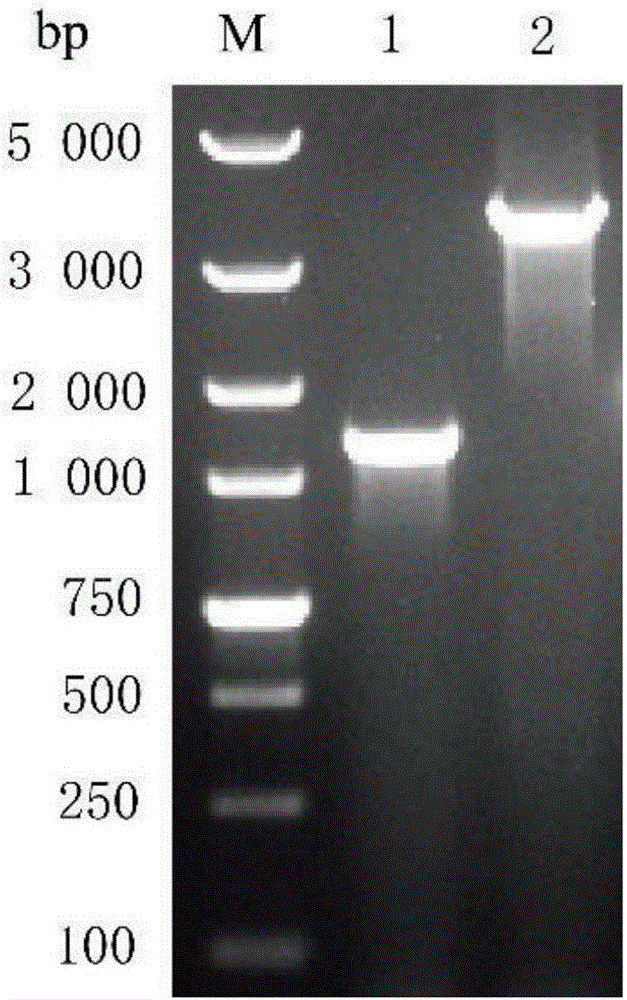

[0064] Using the pKD13 plasmid as a template, the primers FumCpKD3F and FumApKD3R of the fumA and fumC encoding genes of the target gene fumarase were used for polymerase chain reaction, and a linear line with the Kana resistance gene and FRT marker in the middle and short homology arms on both sides was amplified. Homologous recombination fragments. The sequences of FumCpKD3F and FumApKD3R are shown in SEQ ID NO: 1 and SEQ ID NO: 2, respectively.

[0065] Taking the Escherichia coli Escherichia coli BL21 (DE3) preserved in the laboratory as the starting strain, the pKD46 plasmid carrying the Red recombinase (the pKD46 plasmid is reported in the article Datsenko et al., Proc Natl Acad Sci USA, 2000,97:6640-6645 ) into Escherichia coli, and screen the transformant in the Amp-resistant plate medium; insert the transformant into 50mL LB medium with Amp resistance and cultivate overnight at 30°C; insert the same LB medium, and added arabinose at a final concentration of 2mmol / L a...

Embodiment 2

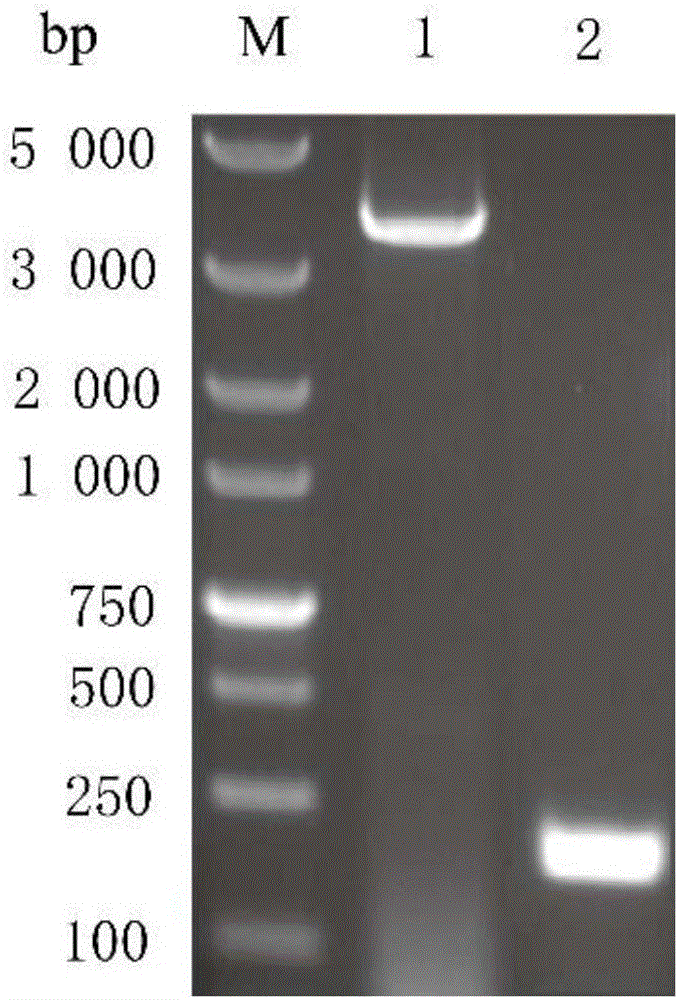

[0069] This example illustrates the construction of strain BL21(DE3)△fumA-fumC / pET24a-maiA and the high-density fermentation expression method.

[0070] The pET24a-maiA plasmid that has been successfully constructed in the laboratory was electrotransformed into the gene knockout Escherichia coli BL21(DE3)△fumA-fumC in Example 1 to obtain the E. coli engineering strain BL21(DE3)△fumA-fumC / pET24a-maiA.

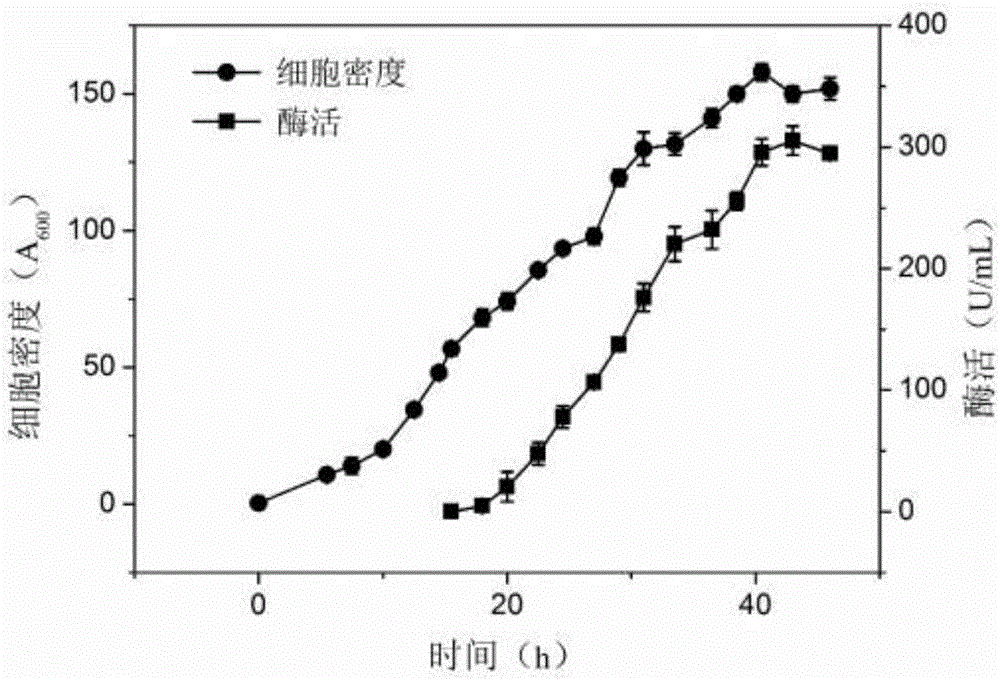

[0071] Streak the above-mentioned E. coli engineered strains stored at -80°C on an LB plate containing 50 μg / mL kanamycin for overnight activation, pick a single colony and inoculate it into a 5 mL LB test tube medium containing 50 μg / mL kanamycin resistance Incubate at 37°C for 8 hours, inoculate 120 mL of fermented seed medium containing 50 μg / mL kana resistance with 1% (v / v) inoculum, and cultivate at 37°C for 7.5 hours as the seed solution in the upper tank, and then inoculate with 7 % of the inoculum was inoculated in the fermentation medium. Cultured in fermentation med...

Embodiment 3

[0073] This example illustrates the ability of the strain BL21(DE3)△fumA-fumC / pET24a-maiA to convert maleic acid into fumaric acid.

[0074] Preparation of the substrate: Weigh 185.7 g of maleic acid solid and add it into 1 L of deionized water, and stir continuously with a magnetic stirrer, adjust the pH to 8.0 with potassium hydroxide, and prepare a 2 mol / L potassium maleate solution.

[0075] With the fermented bacterial liquid in embodiment 2 and the fermented bacterial liquid of original escherichia coli BL21 / pET24a-maiA, carry out the production of fumaric acid as biocatalyst, the ratio of 2mol / L potassium maleate solution and fermented bacterial liquid in the conversion system The conversion temperature was 4:1, and the conversion temperature was controlled at 37°C. After 1.2 hours of conversion, the conversion solution was taken to measure the concentration of maleic acid, fumaric acid and malic acid. It can be seen from Table 1 that during the production process of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com